A Vision for Sustainable Metals

Mission:

Basic Science for SUSTAINABLE METALLURGY, SUSTAINABLE MATERIALS & PROCESSES to avoid greenhouse gas emissions and waste production BEFORE they happen in industry and energy conversion, e.g. reduce greenhouse gas emission & energy costs in

(1) Materials and alloy production

(2) Thermal power generation

(3) Manufacturing and low energy processing

CO2 mitigation comes from AVOIDING emission of CO2.

The strongest lever is recycling where everything can become feedstock.

Limiting global warming can only be achieved through a disruptive reduction of the enormous industrial greenhouse-gas emissions. The numbers speak for themselves. My research therefore focuses on developing sustainable materials and manufacturing routes with the goal of transforming one of humanity’s largest emission sources into a climate-mitigation solution: the production and processing of metals. Each year, more than two billion tons of metals are produced, consuming about 10 % of the world’s total energy and accounting for roughly 40 % of all industrial CO₂ emissions.

I address this challenge from a materials-science perspective: developing hydrogen-based plasma reduction processes as a replacement for carbon-based primary metal production; designing “dirty alloys” from chemically contaminated scrap with up to 95 % lower emissions; and harnessing toxic industrial waste streams as new metal sources. Together, these strategies establish the scientific foundation for a circular, fossil-free economy and could avoid up to 10 % of global CO₂ emissions.

Moreover, the supply of more than 30 critical, strategic, and rare elements increasingly depends on recycling, as many industrial residues today contain metal concentrations up to five times higher than the ores from which they were once extracted.

This quest represents the most profound transformation in materials science since the dawn of the Bronze Age nearly 6,000 years ago and we work on the basic science behind this greatest challenge of our modern industrialised civilisation.

My background: I studied metallurgy and metal physics at RWTH Aachen. After my doctorate 1992 and habilitation 1997 I received a Heisenberg fellowship and worked at Carnegie Mellon University and at the High Magnetic Field Lab in Tallahassee. I joined Max Planck Society as a director 1999. My main research interest is Sustainable Metallurgy, i.e. to make industrial production, use and recycling of materials more sustainable, focusing on basic research with high leverage for CO2 emission mitigation and lower energy consumption. Specific topics are in sustainable metals (specifically ‘green’ steel, Nickel, Aluminium, Titanium etc.), recycling-oriented material design, metal physics behind sustainable production, interfaces, phase transformation, atom probe tomography, materials theory, hydrogen, and artificial intelligence methods in materials science. I received the Gottfried Wilhelm Leibniz Award and two ERC Advanced Grants. I am professor at RWTH Aachen and at KU Leuven. I hold a Doctor Honoris Causa at the Norwegian Technical University. I am member of the German National Science Academy Leopoldina, the US National Academy of Engineering and of the German Engineering Academy Acatech.

Search this website

Metallurgical Sustainability Engineering down to atomic scale

Metals & Metallurgical Research

Metallic materials carry human civilization more than 5000 years, lending even entire ages their name. With a global market of 3500 billion € per year and a daily turnover of 3.5 Billion € in the EU alone materials are key drivers in economy (World Trade Organisation, Optimat Materials Landscaping Study).

The accelerated demand for both, load-bearing and functional materials in key sectors such as energy, sustainability, construction, health, communication, infrastructure, safety and transportation is resulting in predicted production growth rates of up to 200 per cent until 2050 for many material classes.

‘Materials’ are a specific type of matter that is finally used for something, be it a product or process. Therefore materials science has generally both a basic and an applied facet. Nowadays, after virtually thousands of years of development, we still use only about 1000 different types of metallic alloys out of a sheer infinite combinatorial space of about 1060 possible combinations when considering only the 50-60 frequently used elements. This means that we only stand at the beginning of basic research of metals.

These boundary conditions require not only to better understand the fundamental relationships between synthesis, manufacturing, basic mechanisms, microstructure and properties but also to discover novel materials that meet both, advanced application challenges under harsh environments.

Currently several developments are revolutionizing materials research. The first one is the availability of models and artificial intelligence methods with predictive capability such as provided by density functional theory, advanced quasi-particle and continuum simulation methods, computational alloy thermodynamics as well as big data driven tools fueled by machine learning approaches. The second one is the availability and correlative use of high resolution characterization tools such as corrected electron microscopes, atom probe tomography, synchrotron and neutron imaging. The third one is materials synthesis, which stretches nowadays from efficient chemical processing of nanoparticles, thin film synthesis, artchitectured materials, combinatorial casting to additive manufacturing providing fast and flexible routes for materials fabrication.

These enabling techniques meet latest developments in industry and society such as the need for improved sustainability of materials and their manufacturing value chains (e.g. synthesis of alloys and polymers with greenhouse gas emissions); revolutionized drive trains in the transportation sector, i.e the transition from fossile to electrical propelling systems and the way how we provide and store energy.

All these techniques and recent developments enable us to solve some of the most essential challenges in the fields of mobility, energy, infrastructure, medicine and safety.

Along these topics my group works on key fields of highest relevance for society and manufacturing. Examples relate to the following fields:

- Energy (e.g., materials for a hydrogen-propelled industry, hydrogen-tolerant structural alloys, catalysis materials, high temperature alloys, semiconducting materials for photovoltaics and

photo-electrochemistry, fuel cell components, materials for direct solar-thermic components)

- Mobility (e.g., ductile magnesium, steels and magnets for light weight electrical and hybrid vehicles)

- Infrastructure (e.g., high strength and corrosion-resistant alloys for infrastructures, such as wind turbines and chemical infrastructures)

- Medicine & health (e.g., biomedical tribology, compliant implant alloys)

- Safety (e.g., high toughness alloys, cryogenic alloys, coatings and thin film materials, hydrogen tolerant materials).

Some recent papers

Nickel is a critical element in the shift to sustainable energy systems, with the demand for nickel projected to exceed 6 million tons annually by 2040, largely driven by the electrification of the transport sector. Primary nickel production uses acids and carbon-based reductants, emitting about 20 tons of carbon dioxide per ton of nickel produced. Here we present a method using fossil-free hydrogen-plasma-based reduction to extract nickel from low-grade ore variants known as laterites. We bypass the traditional multistep process and combine calcination, smelting, reduction and refining into a single metallurgical step conducted in one furnace. This approach produces high-grade ferronickel alloys at fast reduction kinetics.

Nature April 2025 Sustainable nickel ena[...]

PDF-Dokument [6.1 MB]

Entropy-related phase stabilization can allow compositionally complex solid solutions of multiple principal elements. The massive mixing approach was originally introduced for metals and has recently been extended to ionic, semiconductor, polymer and low-dimensional materials. Multielement mixing can leverage new types of random, weakly ordered clustering and precipitation states in bulk materials as well as at interfaces and dislocations. The many possible atomic configurations offer opportunities to discover and exploit new functionalities, as well as to create new local symmetry features, ordering phenomena and interstitial configurations. This opens up a huge chemical and structural space in which uncharted phase states, defect chemistries, mechanisms and properties.

Multifunctional high-entropy.pdf

PDF-Dokument [2.2 MB]

Metal production involves today 3 steps: extracting metals from ores, mixing into alloys by liquid processing and thermomechanical processing to achieve the desired microstructures. This sequential approach, practised since the Bronze Age, reaches its limit today because of the urgent demand for a sustainable economy: almost 10% of all the greenhouse gas emissions (mostly carbon dioxide) are generated because of the use of fossil-based carbon-containing reductants and high-temperature metallurgical processing with frequent intermediate cooling and re-heating. Here we present a novel sustainable hydrogen-based joint redox synthesis and compaction approach that reforms traditional alloymaking by merging metal extraction, reduction from ores, metal alloying and thermomechanical treatment.

Nature Sept 2024 s41586-024-07932-w One[...]

PDF-Dokument [16.1 MB]

Red mud, a byproduct of bauxite refinement into alumina—the feedstock for aluminium production, is a significant environmental concern due to its sheer volume. Globally, approximately 180 million tons of red mud are generated annually, resulting in an alarming stockpile of 4 billion tons. In this study, we propose a novel approach to transform red mud into valuable and sustainable feedstock using fossil-free hydrogen plasma-based reduction. By doing so, we address a portion of the steel industry's CO2 emissions by enabling the production of several hundred million tons of green steel. The reduction involves rapid liquid-state reduction, chemical partitioning, and density- and viscosity-driven separation between metal and oxides.

Green steel from red mud.pdf

PDF-Dokument [15.5 MB]

OPEN ACCESS: https://pubs.acs.org/doi/10.1021/acs.chemrev.2c00799

- - - - - -

Production of metals stands for 40% of all industrial greenhouse gas emissions, 10% of the global energy consumption, 3.2 billion tonnes of minerals mined, and several billion tonnes of by-products every year. Therefore, metals must become more sustainable. A circular economy model does not work, because market demand exceeds the available scrap currently by about twothirds. Even under optimal conditions, at least one-third of the metals will also in the future come from primary production, creating huge emissions. Although the influence of metals on global warming has been discussed with respect to mitigation strategies and socio-economic factors, the materials science has been less addressed.

acs.chemrev.2c00799_with_volume_ID_s.pdf

PDF-Dokument [6.2 MB]

<< Neues Textfeld >>

Iron making is the biggest single cause of global warming. The reduction of iron ores with carbon generates about 7% of the global carbon dioxide emissions to produce ≈1.85 billion tons of steel per year. This dramatic scenario fuels efforts to re-invent this sector by using renewable and carbon-free reductants and electricity. Here, the authors show how to make sustainable steel by reducing solid iron oxides with hydrogen released from ammonia. Ammonia is an annually 180 million ton traded chemical energy carrier, with established transcontinental logistics and low liquefaction costs. It can be synthesized with green hydrogen and release hydrogen again through the reduction reaction. This advantage connects it with green iron making, for replacing fossil reductants.

Advanced Science - 2023 - Ma - Reducing [...]

PDF-Dokument [2.1 MB]

The chemical space for designing materials is practically infinite. This makes disruptive progress by traditional physics-based modeling alone challenging. Yet, training data for identifying composition–structure–property relations by artificial intelligence are sparse. We discuss opportunities to discover new chemically complex materials by hybrid methods where physics laws are combined with artificial intelligence.

a85cb3e6-26ba-420a-88a8-0a3ef2baa7e0.pdf

PDF-Dokument [2.3 MB]

Han, L., Maccari, F., Souza Filho, I.R. et al. A mechanically strong and ductile soft magnet with extremely low coercivity. Nature 608, 310–316 (2022). https://doi.org/10.1038/s41586-022-04935-3

2022 Nature A mechanically strong and du[...]

PDF-Dokument [14.0 MB]

Toward the design of ultrahigh-entropy alloys via mining six million texts

It has long been a norm that researchers extract knowledge from literature to design materials. However, the avalanche of publications makes the norm challenging to follow. Text mining (TM) is efficient in extracting information from corpora. Still, it cannot discover materials not present in the corpora, hindering its broader applications in exploring novel materials, such as high-entropy alloys (HEAs). Here we introduce a concept of “context similarity" for selecting chemical elements for HEAs, based on TM models that analyze the abstracts of 6.4 million papers. The method captures the similarity of chemical elements in the context used by scientists. It overcomes the limitations of TM and identifies the Cantor and Senkov HEAs. We demonstrate its screening capability for six- and seven-component lightweight HEAs by finding nearly 500 promising alloys out of 2.6 million candidates. The method thus brings an approach to the development of ultrahigh-entropy alloys and multicomponent materials.

It has long been a norm that researchers extract knowledge from literature to design materials. However, the avalanche of publications makes the norm challenging to follow. Text mining (TM) is efficient in extracting information from corpora. Still, it cannot discover materials not present in the corpora, hindering its broader applications in exploring novel materials, such as high-entropy alloys (HEAs). Here we introduce a concept of “context similarity" for selecting chemical elements for HEAs, based on TM models that analyze the abstracts of 6.4 million papers. The method captures the similarity of chemical elements in the context used by scientists. It overcomes the limitations of TM and identifies the Cantor and Senkov HEAs. We demonstrate its screening capability for six- and seven

s41467-022-35766-5.pdf

PDF-Dokument [2.2 MB]

We propose strategies that couple natural language processing with deep learning to enhance machine capability for corrosion-resistant alloy design. First, accuracy of machine learning models for materials datasets is often limited by their inability to incorporate textual data. Manual extraction of numerical parameters from descriptions of alloy processing or experimental methodology inevitably leads to a reduction in information density. To overcome this, we have developed a fully automated natural language processing approach to transform textual data into a form compatible for feeding into a deep neural network. This approach has resulted in a pitting potential prediction accuracy substantially beyond state of the art. Second, we have implemented a deep learning model with a transforme

sciadv.adg7992 - corrosion resistant all[...]

PDF-Dokument [1.5 MB]

High-entropy alloys are solid solutions of multiple principal elements that are capable of reaching composition and property regimes inaccessible for dilute materials. Discovering those with valuable properties, however, too often relies on serendipity, because thermodynamic alloy design rules alone often fail in high-dimensional composition spaces. We propose an active learning strategy to accelerate the design of high-entropy Invar alloys in a practically infinite compositional space based on very sparse data. Our approach works as a closed-loop, integrating machine learning with density-functional theory, thermodynamic calculations, and experiments. After processing and characterizing 17 new alloys out of millions of possible compositions, we identified two high-entropy Invar alloys wit

Machine learning–enabled high-entropy al[...]

PDF-Dokument [1.4 MB]

Nature

Raabe et al Nature Nov 2019 Sustainabili[...]

PDF-Dokument [2.2 MB]

Nature Materials

Sun_et_al-2021-Nature_Materials.pdf

PDF-Dokument [2.7 MB]

Nature | Vol 582 | 25 June 2020

Nanosteel-composite high-strength Damasc[...]

PDF-Dokument [5.2 MB]

Science Advances

Science Advances 2021 The hidden structu[...]

PDF-Dokument [840.7 KB]

Nature Review Materials

Nature Materials Reviews Aug 2019 High-e[...]

PDF-Dokument [2.4 MB]

https://www.nature.com/articles/s41467-019-10012-7

NATURE COMMUNICATIONS | (2019) 10:2090 | https://doi.org/10.1038/s41467-019-10012-7 | www.nature.com/naturecommunications

Oh_et_al-2019-Nature_Communications.pdf

PDF-Dokument [1.5 MB]

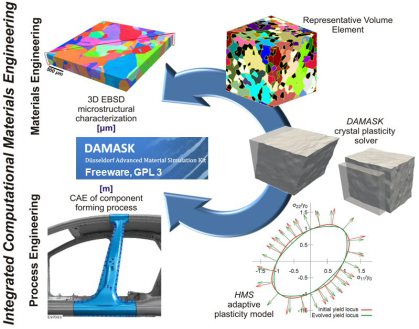

Computational Materials Science

Volume 158, 15 February 2019, Pages 420-478

DAMASK – Duesseldorf Advanced Material S[...]

PDF-Dokument [10.5 MB]

Nature (November 2018)

Nature 2018 strength ductility high-entr[...]

PDF-Dokument [8.2 MB]

Advanced Materials 2018, 1804727

Bidirectional TRIP effect in High Entrop[...]

PDF-Dokument [5.4 MB]

NATURE COMMUNICATIONS (2018) 9:826

Nature Com 2018 interdiffusion in photov[...]

PDF-Dokument [5.6 MB]

PHYSICAL REVIEW LETTERS 121, 015702 (2018)

Strain-Induced Asymmetric Line Segregati[...]

PDF-Dokument [1.9 MB]

SCIENCE vol 349: p. 1080, Sept 2015

Dislocations Linear Complexions Science [...]

PDF-Dokument [1.6 MB]

Nature Catalysis (2018) doi:10.1038/s41929-018-0043-3

Nature Catalysis 2018 - Atomic-scale ins[...]

PDF-Dokument [2.0 MB]

Nature Communications

Silva_et_al-2018-Nature_Communications S[...]

PDF-Dokument [2.7 MB]

Nature 544, 460–464 (27 April 2017)

Ultrastrong steel via minimal lattice mi[...]

PDF-Dokument [6.2 MB]

NATURE | 9 JUNE 2016 | VOL 534 | page 227

Li et al Nature June 2016 Metastable hig[...]

PDF-Dokument [6.0 MB]

Science 355 (6329), 1055-1057 (10. March 2017)

Koyama Bone-like Steels Science 355 (201[...]

PDF-Dokument [745.8 KB]

NATURE COMMUNICATIONS | 8: 751 | DOI: 10.1038/s41467-017-00814-y |

Han_et_al-2017-Nature_Communications Sup[...]

PDF-Dokument [1.1 MB]

Scientific Reports 7: 10458 | DOI:10.1038/s41598-017-10384-0

Ductile Magnesium Calcium Aluminium Scie[...]

PDF-Dokument [2.8 MB]

Scientific Reports 7: 9892 | DOI:10.1038/s41598-017-10774-4

Luo et al 2017 Sci Rep Hydrogen strength[...]

PDF-Dokument [2.5 MB]

NATURE COMMUNICATIONS | 8:14210 | DOI: 10.1038/ncomms14210 |www.nature.com/naturecommunications

Zhang_et_al-2017-Nature_Communications.p[...]

PDF-Dokument [6.2 MB]

Scientific Reports 7:42547 (2017)

Scientific Reports 7 - 42547 Core-shell [...]

PDF-Dokument [2.2 MB]

PHYSICAL REVIEW LETTERS 112, 126103 (2014)

Phys Rev Lett. 2014 grain boundary segre[...]

PDF-Dokument [842.8 KB]

Plasticity experts: You are invited to download and use

DAMASK — the Düsseldorf Advanced Material Simulation Kit

The solution of a continuum mechanical boundary value problem requires a constitutive response that connects deformation and stress at each material point. Such connection can be regarded as three sep

MPIE-DAMASK-Introduction.pdf

PDF-Dokument [1.4 MB]