Hydrogen Embrittlement in Medium Mn Steels

Why are medium Mn steels interesting materials?

Medium Mn steels containing 3 to 12 wt.% Mn have receive high attention, due to the increasing demand for strong and compositionally lean materials with good formability from the automotive industry.

The most widely investigated microstructure of this type of steels consists of ultrafine grained ferrite and austenite, realized by intercritical annealing. Different alloy compositions,

starting microstructures before heat treatment as well as the intercritical annealing conditions can result in a wide range of microstructural characteristics, such as the austenite

fraction (typically ranging from 20 to 70 vol.%, grain size (from below 200 nm up to a few micrometers), phase morphology (globular or laminated), microstructure percolation and dislocation density.

Among these parameters, the fraction of austenite has a crucial influence on the mechanical properties of such steels. For a given alloy composition, a higher austenite fraction typically

corresponds to a lower content

of C and Mn partitioning into austenite, an effect which leads to lower austenite stability and an enhanced transformation-induced plasticity (TRIP) effect. Most studies on such steels

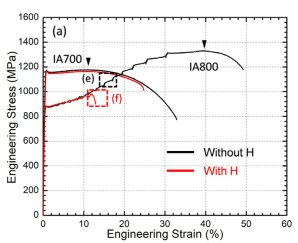

have focused so far on tailoring austenite conditions, in order to achieve an improved strength-ductility combination. The tensile

strength of austenite-ferrite medium Mn steels normally ranges from ~800 to 1400 MPa. This high strength level fuels concerns about hydrogen embrittlement (HE), impeding the use

of these steels.

Why is hydrogen embrittlement important in medium Mn steels?

The risk of hydrogen embrittlement (HE) is currently one important factor impeding the use of medium Mn steels. However, knowledge about HE in these materials is sparse. Their multiphase

microstructure with highly variable phase conditions (e.g. fraction, percolation and dislocation density) and the feature

of deformation-driven phase transformation render systematic studies of HE mechanisms challenging.

Why is the investigation of hydrogen embrittlement in medium Mn steels so challenging?

The HE behavior in medium Mn steels is complex, due to 3 main reasons:

(1) High Mechanical Contrast in medium Mn steels

The high contrast between ferrite and austenite in terms of H diffusivity and solubility makes the H migration and trapping behavior in such steels more complicated than in materials

consisting of a single phase or multiple phases

with similar crystal structures (e.g. ferrite-martensite dual phase steels).

(2) Austenite-ferrite interfaces in medium Mn steels

The austenite-ferrite interfaces are known as strong trapping sites for H. The density and spatial arrangement of such planar defects thus affect H trapping and migration.

(3) Austenite-to-martensite transformation in medium Mn steels

The austenite-to-martensite transformation occurring during deformation resets the local structure and micromechanical state in terms of strain/stress partitioning and localization, as well

as the local thermodynamic driving forces for H migration.

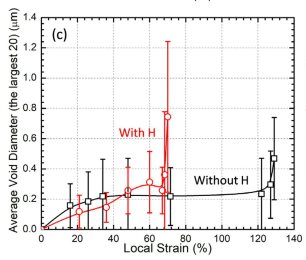

These three factors imply that the change of phase conditions (e.g. fraction, percolation, mechanical stability) in such steels might significantly affect the H trapping and migration and thus also the resulting HE susceptibility.

Which types of mechanisms may occur during the hydrogen embrittlement of medium Mn steels?

the prevalent HE micromechanisms in medium Mn steels are:

(1) Hydrogen-enhanced decohesion (HEDE)

(2) Hydrogen-enhanced local plasticity (HELP)

(3) Adsorption-induced dislocation emission (AIDE).

The former two mechanisms refer to the influence of internal H atoms in the bulk, whereas the AIDE model is based on H adsorption at the crack surface. Therefore, for obtaining a better

understanding of the HE mechanisms in

medium Mn steels, a more comprehensive investigation covering a more systematic range of phase conditions is required.

Acta Materialia 183 (2020) 313–328

Acta 2019 Sun et al hydrogen embrittleme[...]

PDF-Dokument [10.0 MB]

What is hydrogen embrittlement?

Hydrogen’s most striking effect on metallic materials is a sudden and often

unpredictable decrease in ductility, toughness, and generally in the material’s resistance to fatigue-crack propagation referred to as hydrogen embrittlement.

This dangerous phenomenon was discovered as early as 1875 by Johnson but is still not fully understood to date.

The catastropic consquences are revelaed by a recent real-life example: the oil spillage in the Gulf of Mexico in 2012 is attributed to the catastrophic failure of connector bolts due to hydrogen embrittlement.

Hydrogen embrittlement mostly affects structural, high-strength materials that find application in the e.g. automotive, aeronautical, oiland gas and power generation industries.

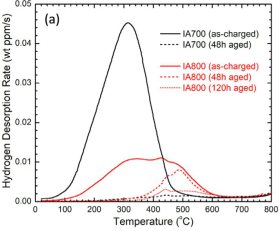

How can we measure solute hydrogen and deuterium in steels?

H is the lightest and smallest of atoms. It is also ubiquitous. Its pres-

ence within the structure of metals cannot be avoided, partly due to its

high mobility. The interactions between H and metals play an essential

role in the structure-property relationships of engineering alloys

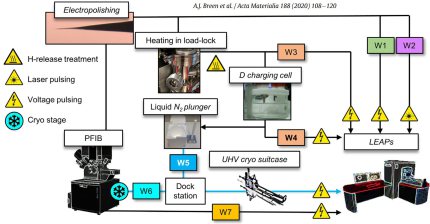

The observation of solute hydrogen (H) and / or dueterium (D) in metallic alloys and generally in matter is particularely a huge yet pressing challenge for better understanding hydrogen embrittlement. Quantitative imaging of H and D at the atomic-scale is critical to understand its deleterious influence on the mechanical strength of many metallic alloys that has resulted in many catastrophic failures of engineering parts and structures. We developed robuts protocols and methodes for the APT analysis of hydrogen (H) and deuterium (D) within the nanostructure of an ultra-high strength steel with high resistance to hydrogen embrittlement.

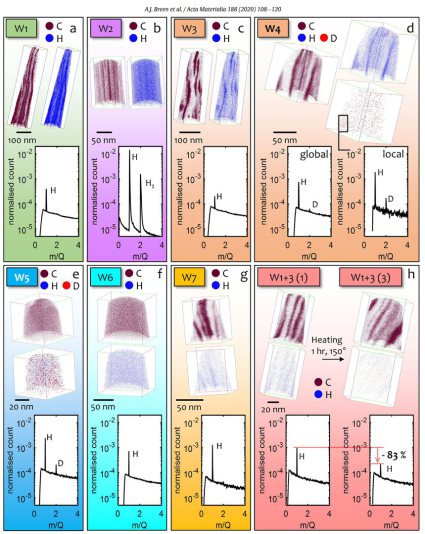

Observing solute hydrogen (H) in matter is a formidable challenge, yet, enabling quantitative imaging of H at the atomic-scale is critical to understand its deleterious influence on the mechanical strength of many metallic alloys that has resulted in many catastrophic failures of engineering parts and structures. Here, we report on the APT analysis of hydrogen (H) and deuterium (D) within the nanostructure of an ultra-high strength steel with high resistance to hydrogen embrittlement. Cold drawn, severely deformed pearlitic steel wires (Fe 0.98C 0.31Mn 0.20Si 0.20Cr 0.01Cu 0.006P 0.007S wt%) contains cementite decomposed during the pre-deformation of the alloy and ferrite. We find H and D within the decomposed cementite, and at some interfaces with the surrounding ferrite. To ascertain t

Acta Materialia 2020 hydrogen deuterium [...]

PDF-Dokument [4.9 MB]

This paper gives an overview of recent progress in microstructure-specific hydrogen mapping techniques. The challenging nature of mapping hydrogen with high spatial resolution, i.e. at the scale of finest microstructural features, led to the development of various methodologies: thermal desorption spectrometry, silver decoration, the hydrogen microprint technique, secondary ion mass spectroscopy, atom probe tomography, neutron radiography, and the scanning Kelvin probe. These techniques have different characteristics regarding spatial and temporal resolution associated with microstructure-sensitive hydrogen detection. Employing these techniques in a site-specific manner together with other microstructure probing methods enables multi-scale, quantitative, three-dimensional, high spatial, an

Recent progress in microstructural hydro[...]

PDF-Dokument [5.3 MB]