ODS Steels: Microstructure and properties of oxide-dispersion strengthened Eurofer steels

If the conventional high-chromium ferritic-martensitic steels, such as modified 9Cr-1Mo or reduced-activation steels, such as 9Cr-2WVTa and EUROFER were used for a fusion power plant first wall and

blanket structure, the upper operating temperature would be limited to 550-600°C.

One plausbile appraoch to shift this limit to higher temperatures and maintain the advantages inherent in ferritic-martensitic steels (i.e. high thermal conductivity and low swelling) is to use

oxide dispersion-strengthened (ODS) steels.

In the tempered state, this steel contains fine particles dispersed in the ferritic matrix. More specific, the elevated temperature strength in these steels is obtained through microstructures that

contain a high density of small Y2O3 and/or TiO2 particles dispersed in a ferrite matrix.

Hence, such oxide dispersion strengthened reduced-activation ferritic–martensitic steels are promising candidates for applications in future fusion power plants.

ODS steels are currently being developed and investigated for both, nuclear fission and fusion applications.

Journal of Nuclear Materials 448 (2014) 33–42:

Oxide-dispersion strengthened ferritic martensitic steels such as ODS-Eurofer grade are good candidates for structural applications in future fusion power reactors. Long-term annealing treatments in vacuum were carried out in cold-rolled samples (80% reduction in thickness) from 1 h up to 4320 h (6 months) at 800 °C, i.e. the maximum temperature in the ferritic phase field, to follow its softening behavior. The microstructural stability of this steel was mapped using several characterization techniques including scanning electron microscopy, transmission electron microscopy, electron backscatter diffraction, Vickers microhardness testing, X-ray diffraction texture measurements, low-temperature electrical resistivity, and magnetic coercive

Journal Nuclear Research 2014 annealing [...]

PDF-Dokument [1'010.2 KB]

R.A. Renzetti et al. / Materials Science and Engineering A 528 (2011) 1442–1447:

Oxide dispersion strengthened reduced-activation ferritic–martensitic steels are promising candidates for applications in future fusion power plants.

MSE-A-vol-528-year2011-page-1442.pdf

PDF-Dokument [983.3 KB]

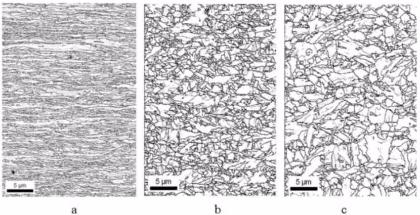

Important microstructural changes occur during annealing of deformed metals including recovery of structural defects, recrystallization, grain growth and other phase transformations.

These changes can be followed by several characterization techniques including classical metallography, hardness testing and electron backscatter diffraction. In this work, we

investigate the annealing

behavior of a ferromagnetic material presenting coercivity below 30 Oe for the initial condition. The magnetic properties of ferritic steels are strongly dependent on their microstructure

[1]. In particular, the microstructure affects the motion of magnetic domain walls and, in consequence, the characteristic parameters of the hysteresis loop. High and low angle boundaries,

dislocations, precipitates and solute atoms act as pinning sites against magnetic domain wall motion [1–6]. Among several magnetic parameters the coercive field (Hc), which is the intensity

of the magnetic field needed to reduce the magnetization of a ferromagnetic material to zero after it has reached magnetic saturation, can be used to monitor microstructural changes in

different materials.

More specific, we suggest that oxide dispersion strengthened reduced-activation ferritic–martensitic steels are promising candidates for applications in future fusion power plants. Samples of a reduced activation ferritic–martensitic

9 wt.%Cr-oxide dispersion strengthened Eurofer steel were cold rolled to 80% reduction in thickness and annealed in vacuum for 1 h from 200 to 1350◦C to evaluate its thermal stability.

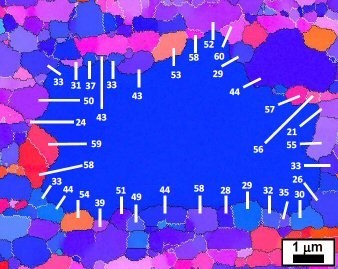

Vickers microhardness testing and electron backscatter diffraction (EBSD) were used to characterize the microstructure. The

microstructural changes were also followed by magnetic measurements, in particular the corresponding variation of the coercive field (H c ), as a function of the annealing treatment. Results show

that magnetic measurements were sensitive to detect the changes, in particular the martensitic transformation,

in samples annealed above 850◦C (austenitic regime).

Materials Science and Engineering A 528 (2011) 1442–1447

MSE-ferritic–martensitic-ODS–Eurofer-ste[...]

PDF-Dokument [2.7 MB]

ODS-EuroFer-steel-fst_v61_n2_pp136-140.p[...]

PDF-Dokument [667.9 KB]

J Nuclear Materials 385 (2009) 231 ODS s[...]

PDF-Dokument [1.4 MB]