Steel Scrap in Sustainable Metallurgy

Sustainable steel via scrap: status, bottlenecks, and research frontiers

Steel production remains one of the most energy- and emissions-intensive industrial sectors globally: it contributes a significant fraction of industrial CO₂ output, consumes large shares of global energy, and drives substantial mineral extraction and waste generation. The transition to more sustainable metallurgy must therefore rely on increasing the share of scrap-based steelmaking and closing material loops. Recycling steel scrap via electric-arc furnaces (EAF) is already an established technology: it reduces energy consumption by roughly 70–75 % compared to primary iron-ore routes, and can cut direct CO₂ emissions per tonne of crude steel by roughly 50–75 %.

Despite the potential, the global uptake of scrap-based steelmaking remains partial: as of the early 2020s, only around 26–30 % of crude steel globally originates from scrap-EAF or secondary routes. This relative stagnation, along with growing future demand for steel, means that steelmaking will continue to produce large CO₂ emissions unless additional material-science and process innovations accelerate the shift to high-quality recycled steel.

Hence, from a materials-science perspective, there is an urgent need to identify and address the scientific bottlenecks that prevent a broader transition to scrap-based, low-carbon steel.

To realize the full potential of scrap-based metallurgy requires solving a wide range of fundamental materials-science, process-engineering, and supply-chain challenges.

This webpage aims to delineate the central scientific and technological issues, assess current progress, and identify open research bottlenecks in sustainable metallurgy built on steel scrap — covering scrap collection and sorting, scrap-based melting (e.g., via Electric Arc Furnace (EAF)), integration with low-carbon reduction routes (e.g., hydrogen or biocarbon), and quality control for high-grade steels.

Steel production accounts for approximately 8% of all global CO2 emissions, with the primary steelmaking route using iron ores contributing approximately 80% of those emissions, mainly due to the use of fossil-based reductants and fuel. Hydrogen-based reduction of iron oxide is an alternative for primary synthesis. However, to counteract global warming, decarbonization of the steel sector must proceed much faster than the ongoing transition kinetics in primary steelmaking. Insufficient supply of green hydrogen is a particular bottleneck. Realizing a higher fraction of secondary steelmaking is thus gaining momentum as a sustainable alternative to primary production.

Raabe et al. Circular Steel for Fast Dec[...]

PDF-Dokument [3.3 MB]

Why Scrap-Based Metallurgy Matters in Sustainable Metallurgy

The conventional steel production route — reduction of iron ore via coke & BF/BOF (blast furnace + basic oxygen furnace) — is highly carbon-intensive. As a result, the steel industry accounts for a substantial fraction of the world’s industrial CO₂ emissions, energy consumption, and mineral extraction.

In contrast, scrap-based routes via EAF use recycled steel instead of iron ore, thereby avoiding the ore reduction step altogether. Because steel is magnetic, scrap can be separated and recycled efficiently.

According to recent data, switching to scrap-EAF combined with renewable electricity or low-carbon reductants (e.g., hydrogen, biocarbon) can reduce specific CO₂ emissions per tonne of crude steel dramatically — recent reviews suggest in ideal cases emissions as low as 0.4–0.8 t CO₂/t steel versus ~2.3 t CO₂/t for BF-BOF.

Moreover, scrap recycling reduces energy consumption: melting scrap in an EAF requires substantially less energy than extracting and reducing iron from ore.

Because of these advantages, scrap is increasingly regarded as a strategic resource — especially in regions aiming for climate-neutral steel.

Sustainable Metallurgy: scrap-based steelmaking today

Environmental and energy benefits

-

According to data for the European Union, replacing primary production with recycled scrap reduces energy demand by ~72%.

-

For every tonne of recycled steel used, roughly 1.4 tonnes of iron ore, 0.8 tonnes of coal, and 0.3 tonnes of limestone are spared. Additionally, about 1.67 tonnes of CO₂ are avoided per tonne of steel recycled.

-

At scale, scrap-based production using electricity — especially from renewables — can bring CO₂ emissions per tonne close to zero, rendering scrap-EAF a cornerstone technology for decarbonizing steel in the near to medium term.

From an economic standpoint, scrap-EAF routes are already cost-competitive with conventional blast-furnace/basic-oxygen-furnace (BF-BOF) routes, especially when average scrap and electricity prices are favorable.

Practical uptake, potential and regional variation

-

In the United States, scrap-EAF accounts for ~71% of crude steel production (2020 data). In the EU, the proportion was ~42%.

-

Many regions with high steel demand, such as China, Japan, and South Korea, still rely predominantly on BF-BOF, indicating significant potential for expansion of scrap-EAF.

-

According to modeling studies, under climate-policy scenarios (e.g., the IEA “Net Zero by 2050”), scrap-based steelmaking could supply up to 46% of global steel by 2050.

However, several fundamental challenges remain — many of them rooted in materials science and contamination rather than energy supply or economics.

Impurity Contamination - especially Copper - in Sustainable Steel Metallurgy

Impurity elements (e.g., copper, phosphorus, other residuals) embedded in scrap severely limit the ability to produce high-grade steels. Among them, copper is particularly pernicious:

-

As reviewed by Raabe et al., copper contamination in scrap is pervasive and current industrial practice lacks a commercial method to reliably remove copper once it is already in the molten steel.

-

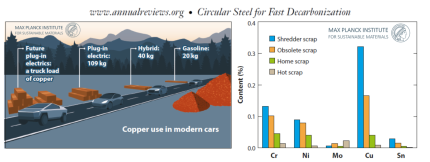

Copper accumulates during use and life-cycle of ferrous products (bridges, building steel, appliances). Post-consumer scrap streams thereby tend to concentrate copper and other residuals, which degrade mechanical properties and impede achieving high-performance or sensitive grades (e.g., automotive high-strength steel or fine sheet).

-

Efforts to re-melt scrap for “high quality steel products” thus remain strongly influenced by initial scrap quality and composition.

-

The quality of scrap strongly depends on its provenance, previous use, mix of alloying and residual elements, and contamination. Yet scrap is often traded and used without detailed, reliable compositional information. This lack of traceability impairs process control and steel quality outcomes.

Neither standard desulfurization, dephosphorization, nor deoxidation treatments reliably eliminate copper once incorporated — copper partitions unfavorably and segregates, leading to precipitates, embrittlement or other deleterious effects.

Quality-sensitive steel grades and performance requirements in scrap-based sustainable steel metallurgy

-

While scrap-EAF steel is well suited for structural, construction, and general-use steels (where impurity tolerances are wider), many advanced applications — automotive, high-strength alloys, critical structural components — demand much more tight and consistent control of chemistry, microstructure, and properties. Current scrap-based routes struggle to deliver such consistently for high-end grades.

-

Downstream refining, alloying, and purification steps add complexity, energy cost, and may erode some of the environmental gains of scrap recycling.

-

Deep-learning classifiers combined with conformal prediction — to quantify uncertainty — can i P achieve >90% classification accuracy over several thousand images across multiple scrap classes, enabling more reliable, automated scrap sorting. This is clearly a way to go.

-

In scrap-based EAFs, predicting final concentrations of residual elements (e.g., phosphorus) is critical for process control. A recent study employed an artificial neural network (ANN) to forecast final P content based on inputs like scrap composition, oxygen injection, process duration. The model achieved an R² of 99.96% and prediction error within ±10 ppm. Such data-driven tools allow real-time or near-real-time decision making — scrap batch selection, oxygen dosing, fluxing — to minimize impurity retention, reduce reject rates, and improve yield of high-grade steel from scrap.

Integrating scrap with low-carbon virgin iron: hybrid steelmaking routes

-

Recognizing the intrinsic limit to scrap availability and quality, a hybrid strategy combining scrap with low-carbon virgin iron (e.g., from direct reduced iron (DRI), hydrogen-based reduction, or novel processes) is gaining attention. The general framework for such integrated strategies — considering primary, secondary, tertiary sources and downstream processing — is articulated in the materials science community.

-

For example, a continuous value chain combining scrap-EAF with DRI (from green hydrogen) would allow steelmakers to balance impurity management, quality requirements, and carbon mitigation, delivering “green steel” as functionally equivalent to conventional but with far lower emissions.

A few basic scientific and research challenges in sustainable scrap based steel metallurgy and scrap based alloy design

Fundamental mechanisms of impurity behavior (especially copper) in scrap-based melts

-

What thermodynamic and kinetic behaviors govern copper (and other residuals) segregation, precipitation, or retention during scrap melting, refining, and solidification?

-

Are there alloying or fluxing strategies, or novel refining routes (e.g., slag chemistry, slag-metal partitioning, reactive gases) that could reduce copper content below critical thresholds for high-grade steel?

Quantitative scrap composition–property–performance relationships

-

How does variability in scrap composition (residuals, tramp elements, non-ferrous inclusions) map onto final steel microstructure, impurity distributions, and mechanical or corrosion performance?

-

Can advanced statistical / machine-learning models coupled with microstructural characterization yield predictive frameworks to guide scrap blending and process parameters?

Optimized scrap sorting and classification workflows at scale

-

What combination of sensor technologies (optical, spectroscopic, AI-driven imaging, chemical analysis) yields robust, cost- and time-efficient scrap classification, suitable for industrial throughput?

-

What are the best practices to certify scrap batches for quality and traceability, ensuring reliable supply of high-grade feedstock?

Hybrid production chains combining scrap and low-carbon virgin iron

-

From a materials-science standpoint: how to integrate scrap-derived steel with DRI or green-iron feedstocks without compromising quality, while maximizing carbon reduction?

-

What alloy design and processing strategies can handle mixed inputs (scrap + virgin) to meet stringent performance requirements (e.g., automotive, structural)?

Full life-cycle and circular economy metrics, underpinned by metallurgy

-

Development of robust material-flow models that couple scrap generation, collection, recycling, and re-use with metallurgical performance — to forecast realistic maximal scrap utilization and decarbonization potential in different regions.

-

Life-cycle assessment (LCA) and techno-economic analysis that incorporate scrap quality constraints, scrap sorting and treatment costs, energy demand, emissions, and alloy yield losses.