Sustainable metals from recycling scrap: The science of “dirty” alloys: The case of aluminium alloys

Recycling of High Performance Aluminium Alloys into Performance Aluminium Alloys: Sustainability Dimensions of Aluminum Metallurgy and Circular Resource Management

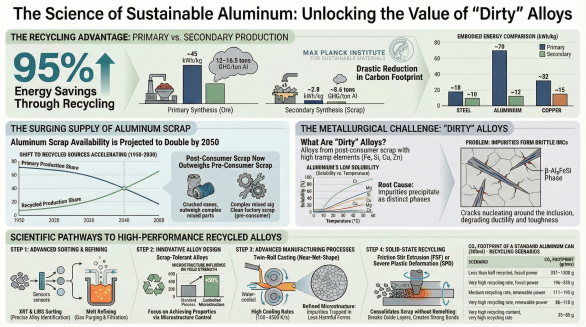

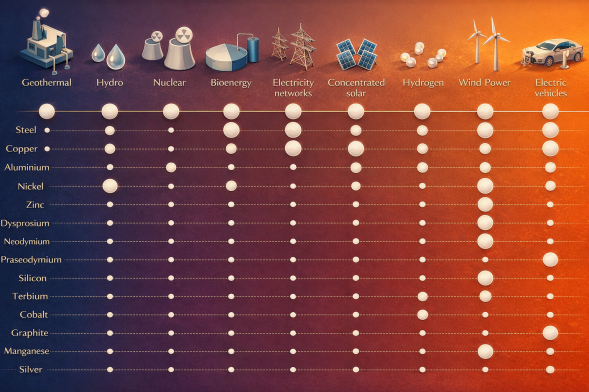

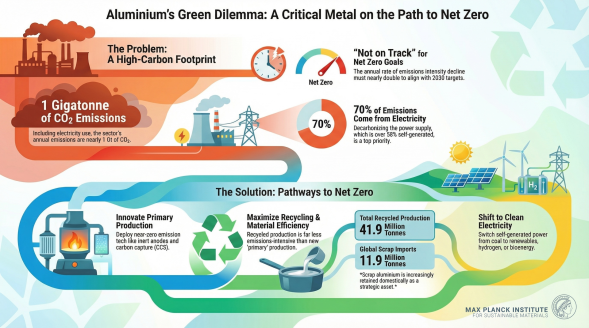

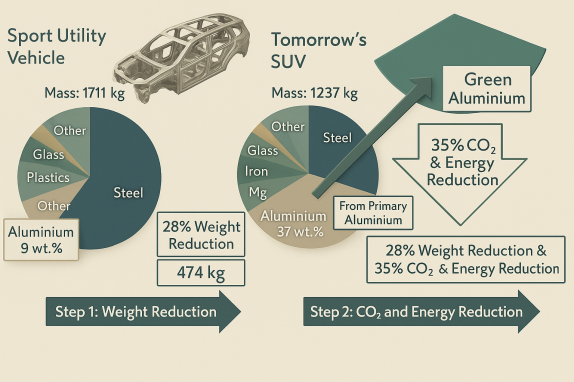

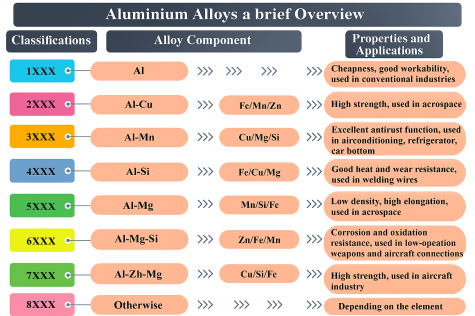

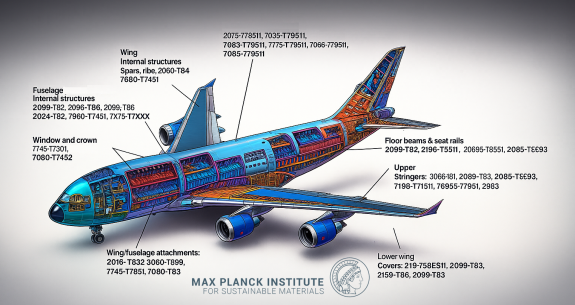

Aluminum occupies a singular position within materials science regarding both sustainability challenges and opportunities. The metal's exceptional properties—particularly its low density coupled with high strength-to-weight ratios—make it indispensable for weight reduction across automotive, aerospace, and transportation applications, directly enabling substantial fuel economy improvements and operational energy savings. However, this sustainability benefit is substantially offset by the thermodynamic demands of primary production from bauxitic ore. The complete extraction and processing sequence—encompassing bauxite mining, alumina refining via the Bayer process, and electrolytic reduction in Hall-Héroult cells—demands approximately 186 gigajoules of primary energy per tonne of aluminum produced globally, generating corresponding carbon emissions of approximately 15.1 tonnes of CO₂ equivalent per tonne from mine to cast house operations.

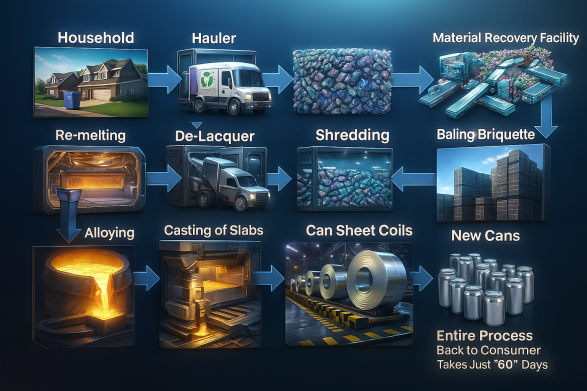

The transition from primary to secondary synthesis represents a fundamental decarbonization pathway. Secondary aluminum production via scrap remelting requires only 8.3 gigajoules of primary energy per tonne, representing an energy intensity reduction of 95.5 percent compared to primary production. This dramatic differential reflects the elimination of energy-intensive mining and beneficiation operations, the bypass of alumina refining requirements, and the substitution of direct-arc melting for electrolytic reduction. The corresponding carbon footprint reduction reaches approximately 0.52 tonnes of CO₂ equivalent per tonne for recycled aluminum, compared to the 15.1 tonne baseline for primary material—a mitigation of 96.6 percent in direct production-phase emissions.

Open Access: Progress in Materials Science

Progress in Materials Science 128 (2022) 100947

https://www.sciencedirect.com/science/article/pii/S0079642522000287?via%3Dihub

OPEN ACCESS - Making sustainable aluminu[...]

PDF-Dokument [4.8 MB]

Open Access: Acta Materialia 289 (2025) 120932

Acta Full paper Al Si recycling 01-s_Opt[...]

PDF-Dokument [2.1 MB]

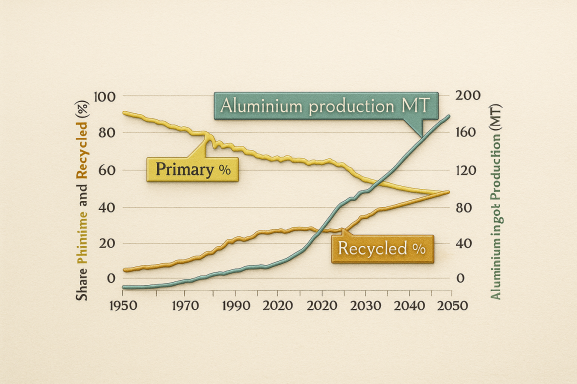

Scrap Resource Availability for the Case of Aluminium Alloys and Circular Economy Potential

The growth trajectory of post-consumer scrap availability presents substantial economic and environmental opportunity. Post-consumer aluminum scrap collection reached approximately 20 million tonnes in 2019, with projections indicating that the total pool of recyclable aluminum will more than double by 2050, rising from current flows of 3.6 million tonnes annually to approximately 8.6 million tonnes by mid-century. Under optimized collection and recycling infrastructure scenarios, recycled aluminum could satisfy roughly 50 percent of total aluminum demand by 2050 in mature economies, particularly the European Union. Realization of these recovery targets would avoid approximately 39 million tonnes of annual CO₂ emissions by 2050, contingent upon successful implementation of collection systems, sorting infrastructure, and remelting capacity in appropriate geographic regions.

The economic implications are equally substantial. Advanced recycling operations could generate annual economic value approaching 12 billion euros across Europe alone by 2050, contingent upon effective aggregation of scrap streams and segregation of alloy families. This economic stimulus derives both from avoided primary production costs and from the reduced capital equipment requirements for secondary production—recycled aluminum requires only approximately 10 percent of the capital equipment costs compared with primary smelting infrastructure.

Market Transformation and the (partially) "Green Aluminum" Framework

The metallurgical industry has undergone significant market-driven transformation in recognition of these sustainability differentials. Beginning in 2020, the London Metal Exchange (LME) established a carbon-certified trading platform for low-carbon aluminum, providing market transparency and premium pricing mechanisms for sustainably produced metal. The initial carbon threshold of 13 tonnes CO₂ equivalent per tonne was subsequently revised downward to 10 tonnes CO₂ equivalent per tonne in response to market feedback, reflecting the ambition of establishing verifiable benchmarks aligned with industry decarbonization trajectories. This initiative, operationalized through the Metalshub platform and supported by certification frameworks including the International Aluminium Institute carbon footprint methodology and the Aluminium Stewardship Initiative Performance Standard, represents institutional recognition that material sustainability will become progressively determinative in procurement decisions. Market participants anticipate that future regulatory frameworks may impose restrictions on high-carbon primary aluminum in construction and consumer applications, thereby accelerating substitution toward recycled and low-carbon certified sources.

Recycling-related Compositional Challenges in Post-Consumer Scrap for Making High Performance Aluminim Alloys

The transition toward circular aluminum systems, however, confronts material science constraints that have historically limited the technical feasibility and economic viability of high-scrap-content alloy production. Approximately two-thirds of the scrap stream originates from post-consumer sources—including retired beverage containers, automotive components, building systems, and consumer goods—presenting unavoidable contamination by elemental impurities fundamentally different from the chemistry of target alloys.

The primary challenge arises from the thermodynamic solubility characteristics of aluminum. Unlike iron or steels, which tolerate relatively high concentrations of impurity elements through solid-solution or carbide phases, aluminum demonstrates exceptionally low solid-solution tolerance for most transition metals and metalloids. Common scrap contaminants include iron (Fe), copper (Cu), zinc (Zn), silicon (Si), nickel (Ni), lead (Pb), chromium (Cr), vanadium (V), and manganese (Mn), each of which can originate from heterogeneous source products or from commingling of alloy grades during collection. Iron, deriving both from manufacturing equipment and from mixed-alloy streams, represents a particularly intractable contamination vector, as it is mechanically difficult to remove at the scrap preparation stage and demonstrates minimal affinity for extraction during pyrometallurgical processing.

Precipitation Thermodynamics and Relevance of Kinetics

Incorporation of multiple scrap-related contaminant elements forces aluminum alloy systems to operate within multicomponent equilibrium regimes fundamentally different from conventional binary or ternary alloy designs. Rather than occupying a well-defined point in established phase space, scrap-based alloys exhibit composition trajectories that traverse high-dimensional chemical spaces with fifteen or more compositional variables simultaneously active. This compositional variability directly perturbs the thermodynamic driving forces and kinetic pathways governing precipitation reactions central to mechanical property development.

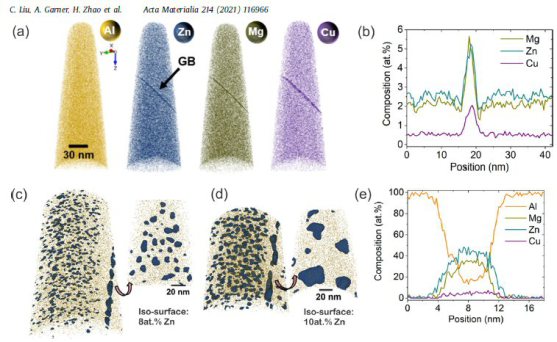

In age-hardenable aluminum alloys (particularly 6xxx and 7xxx series), strength development depends critically upon controlled precipitation of phases such as Mg₂Si, η′ (Mg(Cu,Zn)₂ in 7xxx alloys), and related strengthening precipitates. The presence of iron-bearing impurities, for example, shifts equilibrium phase boundaries through stabilization of intermetallic phases (including AlFeMn and other Fe-rich compounds) that nucleate and grow in preference to the intended strengthening precipitates. This phase competition fundamentally alters the nucleation energetics, growth kinetics, and coarsening behavior of the desired precipitate population, typically resulting in reduced precipitate number density, altered size distributions, and consequently diminished mechanical properties.

Copper contamination presents a distinct thermodynamic complication. While copper comprises intentional alloying additions in 7xxx-series systems, uncontrolled copper concentration from scrap amalgamation promotes formation of coarse intermetallic phases at grain boundaries and within the bulk, alongside elevation of matrix copper supersaturation that disrupts the kinetic sequence of age-hardening precipitation. The thermodynamic modeling of such multicomponent systems, incorporating CALPHAD (CALculation of PHAse Diagrams) methodology coupled with precipitation kinetics simulation, reveals that the driving force for formation of undesired phases often exceeds that of intended strengthening phases, particularly during early-stage nucleation and growth.

Precipitation-Free Zones in Alumunium Alloys and Grain Boundary Phenomena

Scrap-related contaminants profoundly affect the micromechanical behavior at grain boundaries—regions of critical mechanical significance in polycrystalline metals. During artificial aging heat treatments, solute atoms and quenched-in vacancies preferentially migrate toward grain boundaries via fast-diffusion pathways, generating two competing phenomena: (1) coarse, stable grain boundary precipitate phases, and (2) precipitation-free zones (PFZs) extending approximately 50 to 160 nanometers into the adjacent matrix.

The formation of PFZs arises through either vacancy depletion (in which sinks at grain boundaries remove excess vacancies below critical concentrations necessary for nucleation) or solute depletion (where coarse boundary precipitates consume solute, reducing matrix supersaturation). Contaminant elements substantially modify both mechanisms. Iron-rich intermetallics preferentially nucleate at grain boundaries, amplifying coarse boundary phase formation and extending solute-depleted regions. Zinc and magnesium contamination alters the partitioning of solute elements between boundary regions and the matrix, shifting the width and composition of PFZs. The widening or narrowing of PFZs directly determines the localization of plastic deformation during loading; excessively wide PFZs become mechanical weak points susceptible to premature void nucleation and crack initiation.

Acta Mater 2021 CALPHAD-informed phase-f[...]

PDF-Dokument [6.8 MB]

Acta Mater 2018 Segregation assisted gra[...]

PDF-Dokument [4.6 MB]

Electrochemical and Corrosion Implications for Recycled Aluminium Alloys

The electrochemical stability of aluminum alloys depends fundamentally upon formation of a protective aluminum oxide passive film and upon minimization of galvanic couples between noble intermetallic phases (which act as cathodes) and the surrounding aluminum matrix (which becomes anodic). Scrap-derived impurities directly compromise both mechanisms. Iron-bearing intermetallic compounds possess nobility approaching that of copper, generating galvanic potential differences of 0.5 to 1.0 volts relative to the aluminum matrix. Under aqueous or saline exposure, these particles establish galvanic couples wherein the matrix preferentially dissolves as the anodic component. This localized corrosion mechanism proceeds even in relatively benign environments—fresh water or neutral chloride solutions—provided microstructural partitioning of iron-rich phases has occurred.

Copper contamination, whether from intentional dissolution into solid solution or from discrete copper-bearing intermetallic phases, similarly establishes galvanic couples and promotes pitting corrosion through formation of noble aluminum-copper intermetallic particles. The corrosion resistance of contaminated scrap-based alloys degrades non-linearly with increasing copper or iron concentration; even modest impurity levels (0.05 to 0.15 weight percent) can reduce time-to-initiation for pitting corrosion by factors of three to five compared with high-purity baseline compositions. Lead and chromium segregation at grain boundaries introduces additional electrochemical heterogeneity, promoting intergranular corrosion pathways. Zinc contamination, paradoxically, can simultaneously improve some aspects of mechanical property retention (through precipitation strengthening effects) while worsening electrochemical stability through formation of zinc-containing galvanic couples.

How solute atoms control aqueous corrosi[...]

PDF-Dokument [2.5 MB]

Casting Microstructure and Processing Challenges for Recycled Aluminim Alloys

Secondary aluminum casting alloys experience substantial microstructural evolution as scrap content increases. The incorporation of iron-rich master alloys and naturally occurring iron segregation from scrap sources promotes formation and coarsening of AlFeMn and related intermetallic phases within the as-cast microstructure. High-pressure die casting (HPDC) processes, which employ rapid solidification rates, partially mitigate this coarsening relative to conventional direct chill or semi-direct casting. However, studies of high-scrap-content castings (exceeding 50 to 75 percent returnable material) document progressive coarsening of silicon particles (particularly problematic in AlSi casting alloys) and increased macroscopic porosity and macroinclusivity with elevated scrap fractions.

Thermal gradient and solidification rate engineering—particularly through mold design optimization and controlled cooling—can partially compensate for contaminant-induced coarsening. Ultrasonic grain refinement techniques and rare-earth microalloying (using scandium, yttrium, or cerium additions) have demonstrated capability to substantially refine intermetallic morphology and reduce segregation. However, such mitigation approaches incur additional cost and complexity, offsetting some of the economic benefits of secondary aluminum.

Alloy Design Strategies for Scrap Compatibility and Composition Tolerance

Addressing these materials science challenges requires fundamental reconceptualization of aluminum alloy design philosophy. Rather than optimizing alloys for narrowly constrained compositional windows compatible with primary aluminum, forward-looking strategies propose development of "scrap-compatible" and "composition-tolerant" alloys that maintain acceptable mechanical, functional, and chemical properties across intentionally broadened composition ranges.

Several design approaches have emerged. First, the "composition-flexible" strategy involves identifying multicomponent composition domains (spanning typically 5 to 15 composition axes) wherein various scrap mixtures and metallurgical impurities can be accommodated without catastrophic property loss. Machine-learning clustering algorithms, combined with phase stability screening and corrosion resistance filtering, have enabled consolidation of existing alloy families—for example, reducing the current 6xxx-series portfolio of approximately 42 distinct alloys into optimized subsets of 8 to 10 "master" alloys capable of accepting scrap-derived compositional variation while maintaining adequate properties for target applications.

Second, "crossover" or "uni-alloy" design strategies seek to develop intermediate compositions with chemical overlap between existing alloy classes (e.g., 5xxx and 6xxx series, or 6xxx and 7xxx series). Such alloys, if engineered to achieve adequate property profiles through controlled precipitation and grain refinement rather than through strict compositional specification, could increase recyclability and reduce the penalties associated with alloy commingling.

Third, compositionally lean alloy strategies deliberately reduce reliance on fine compositional tuning for property development, instead emphasizing controlled microstructural development and processing parameter optimization. Alloys designed to achieve strength and ductility primarily through dislocation density, grain size, and precipitate density—rather than through precise alloying element concentrations—exhibit greater inherent tolerance to composition variability from mixed scrap.

Fourth, advanced solid-phase processing techniques, including friction extrusion, enable direct conversion of low-value scrap (such as 6063 wrought scrap) into high-strength products without conventional melt-based remelting. These techniques, when coupled with targeted alloying additions (copper, zinc, magnesium powder additions), facilitate formation of nanostructured precipitate assemblies (Guinier-Preston zones and ordered precipitate phases) that achieve strength increases exceeding 200 percent compared to conventional melted secondary alloys, effectively "upcycling" scrap to higher-value products.

Thermomechanical Processing and Heat Treatment Optimization for Recycled Aluminium Alloys

Processing parameter adjustment represents an underutilized lever for compensation of scrap-induced compositional variability. Controlled solution treatment (temperature and time), quenching rate specification, and artificial aging regime customization can substantially mitigate mechanical property degradation caused by impurity-induced phase complications. For example, elevated quenching temperatures can suppress formation of undesirable intermediate phases (such as iron-rich intermetallics), while slower heating rates during solution treatment can promote more complete dissolution of contaminant-bearing phases before quenching.

Artificial aging kinetics exhibit strong temperature and time dependence; modification of aging schedules can shift the competitive balance between undesired phases (promoted by contaminants) and intended strengthening phases. Higher aging temperatures accelerate diffusion and may favor formation of more stable phases while suppressing metastable strengthening precipitates, whereas lower aging temperatures with extended hold times can enhance desired precipitation kinetics despite contaminant-induced nucleation barriers.

Importantly, the relationship between deformation (through thermomechanical processing) and precipitation kinetics proves particularly powerful in contaminated systems. Applied strain substantially reduces nucleation barriers for precipitate formation through dislocation multiplication, enabling enhanced precipitation of desired phases even when thermodynamic driving forces are diminished by contaminant elements. Controlled deformation during aging heat treatment—realized through warm rolling, extrusion, or other thermomechanical operations—can therefore effectively compensate for the impurity-induced thermodynamic disadvantages.

Material Flow Considerations and Scrap Fractionation

Effective implementation of scrap-compatible alloy strategies depends critically upon sophistication of scrap collection, sorting, and fractionation infrastructure. Current practice achieves significant segregation between preconsumer scrap (generated during alloy production and fabrication, typically <1 percent contamination) and post-consumer scrap (from end-of-life products, containing 5 to 15 percent elemental contamination). However, post-consumer scrap remains largely commingled with multiple alloy families, limiting downstream utilization options.

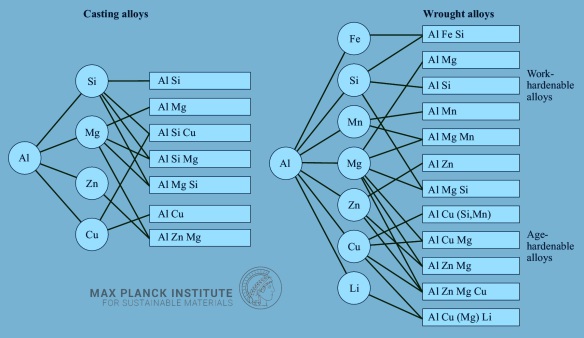

Advanced sortation technologies—including X-ray fluorescence (XRF), X-ray transmission (XRT), and laser-induced breakdown spectroscopy (LIBS)—enable progressive segregation of post-consumer scrap into distinct composition fractions (cast alloys, 5xxx-series (Al-Mg), 6xxx-series (Al-Mg-Si), and 7xxx-series (Al-Zn-Mg-Cu) categories). This fractionation allows targeted matching of scrap composition to alloy families capable of accommodating the impurity profile, substantially reducing downcycling penalties. The "Zorba" process, exemplifying advanced sortation, employs sequential XRF/XRT/LIBS analysis followed by air-knife sorting to separate mixed scrap into composition-appropriate fractions suitable for direct secondary alloy production.

Current limitations include the capital intensity and operational complexity of advanced sortation infrastructure, which remains economically viable only at substantial scale (typically >50,000 tonnes annually). However, continued deployment of XRF and LIBS technologies, coupled with automation advances, projects unit-cost reductions that will improve economic viability at smaller scales within the next 5 to 10 years.

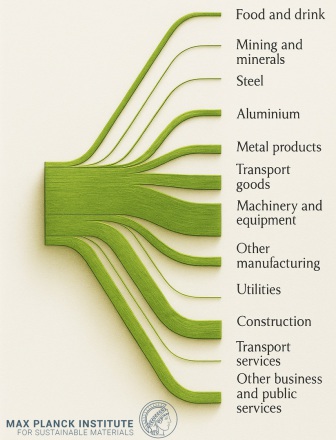

Circular Economy Pathway and Future Technological Horizons

The transition toward circular aluminum metallurgy represents a fundamental systems-level transformation extending beyond materials science to encompass logistics, policy, and market structure. The European Union's recent circular economy framework establishes mandatory recycled-content requirements for beverage-can manufacturers (increasing from 25 percent recycled content by 2025 to 30 percent by 2030), while product design for disassembly standards are progressively incorporated into automotive and construction specifications.

The objective of current research and industrial development initiatives is multifaceted: to foster design and production of aluminum alloys with progressively higher scrap fractions; to enable valorization of currently low-quality, contaminated scrap streams; and to reduce dependence on scrap types that match only limited target alloys in existing recycling systems. Success in these domains would effectively dissolve the current technical and economic barriers separating post-consumer scrap from high-value wrought alloy applications, fundamentally restructuring the aluminum material cycle toward near-perfect material recoverability.

Future horizons include hyperalloy engineering via machine-learning-assisted composition optimization, wherein multicomponent equilibrium modeling integrated with machine learning enables prediction of alloy design spaces capable of accommodating broader contamination ranges. Integration of digital material passports (tracking composition, thermal history, and mechanical properties through product lifecycles) would enable more sophisticated closed-loop recycling systems wherein scrap composition can be precisely characterized and intentionally directed toward compatible alloy production systems.

The achievement of these objectives—realizing aluminum recycling fractions approaching 50 to 60 percent of global supply by 2050, with contaminated post-consumer scrap routinely converted to high-performance alloys rather than downcycled to castings—depends upon sustained advancement across multiple domains: fundamental thermodynamic and kinetic understanding of multicomponent precipitation in contaminated systems; development of composition-tolerant alloy architectures; advancement of processing technologies capable of compensating for compositional heterogeneity; and deployment of sorting infrastructure enabling scrap streams to be optimally routed to compatible alloy systems. This coordinated advancement would constitute a genuine materials science revolution, transforming aluminum from a material of hidden environmental cost into a genuinely circular, perpetually recyclable resource.