Incentives for Aluminium Recycling: Motivation for producing and using scrap-based aluminum alloys

Aluminum Production and Global Sustainability: A Dual Environmental Reality

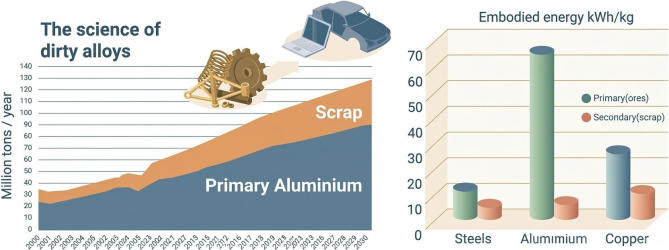

Approximately 110 million metric tons of aluminum are produced annually on a global basis, with roughly 35 to 37 percent of this supply derived from post-consumer and end-of-life scrap recycling, and an additional 40 percent recovered directly within the manufacturing and conversion chain through pre-consumer scrap utilization. The remaining approximately 25 percent is generated through primary production from bauxitic ore reduction. This material composition reveals aluminum's paradoxical sustainability profile.

The Dual Nature of Aluminum in Global Systems

Aluminum presents a fundamentally contradictory environmental position regarding global sustainability objectives. On one hand, the metal significantly reduces operational energy consumption across multiple industrial and commercial sectors—particularly lightweight transportation, beverage and food packaging, and structural construction applications—due to its exceptionally low mass density of 2.70 kilograms per cubic decimeter. The weight reduction achieved through aluminum substitution for heavier materials (such as steel) directly translates to reduced fuel consumption and operational energy demand throughout the product lifecycle.

Aluminum additionally serves as an efficient conductor of electrical current, particularly advantageous in applications requiring minimal electrical resistance coupled with lightweight performance characteristics. With an electrical conductivity of approximately 3.7 × 10⁶ amperes per volt-meter at standard conditions (20°C), pure aluminum achieves approximately 64 percent of the conductivity of pure copper (which exhibits conductivity of approximately 5.8 × 10⁶ amperes per volt-meter) while simultaneously maintaining a mass approximately one-third that of copper. When evaluated on a mass-normalized basis—considering electrical conductivity per unit mass—aluminum demonstrates superior performance to copper by a factor of approximately 2.0 to 2.4, rendering it the preferred conductor material in applications where weight reduction constitutes a critical design objective.

Conversely, aluminum production constitutes one of the most energy-intensive industrial metallurgical processes and remains a major contributor to global greenhouse gas emissions across the industrial sector. The production process releases multiple potent greenhouse gases and hazardous by-products, including carbon dioxide, carbon tetrafluoride (CF₄), hexafluoroethane (C₂F₆), sulfur hexafluoride (SF₆), perfluorocarbons generally, methane, nitrous oxide (N₂O), and sulfur dioxide.

Quantitative Greenhouse Gas Impact

Globally, aluminum production accounts for approximately 1.1 to 1.2 gigatons of carbon dioxide equivalent (CO₂e) per year, representing approximately 2.0 to 2.3 percent of total global anthropogenic greenhouse gas emissions and approximately 15 to 17 percent of all industrial sector emissions specifically. This substantial contribution reflects the thermodynamic and electrochemical demands intrinsic to aluminum metallurgy at scale.

Primary aluminum production—the conversion of refined aluminum oxide (alumina) to metallic aluminum through Hall-Héroult electrolytic reduction—generates between 12 and 16.5 tonnes of CO₂ equivalent for every tonne of metal produced, depending upon the regional electricity grid composition, smelter technology vintage, and operating efficiency characteristics. As of 2023, the global average greenhouse gas intensity of primary aluminum production stands at 14.8 tonnes of CO₂ equivalent per tonne, representing a modest improvement from historical baselines but remaining substantially elevated relative to secondary production pathways.

Approximately 65 percent of these cumulative sector emissions derive directly from electricity consumption during electrolytic smelting, and approximately 67 percent of the electrical energy consumed globally for aluminum electrolysis originates from fossil fuel–based electricity generation, predominantly coal-fired power plants. Analysis of 2019 electrical consumption data indicates that coal-generated electricity supplied 588 terawatt-hours (TWh) of the 918 TWh total electrical consumption for aluminum electrolysis globally, representing a dependence on coal generation that has intensified substantially since 2006, when coal contributed only 49 percent of aluminum electrolysis power. This escalating coal dependence—driven primarily by construction of captive coal power plants servicing new Chinese smelting capacity—resulted in coal-fired electrolysis generating approximately 636 million tonnes of CO₂ emissions in 2019 alone, equivalent to 58 percent of the global aluminum sector's total carbon footprint.

The aluminum industry consumes approximately 13 exajoules of primary energy on an annual basis globally, representing approximately 1 percent of total worldwide energy consumption. Within this energy budget, electrolytic reduction of alumina accounts for the dominant share, requiring 13,500 to 16,700 kilowatt-hours of electrical energy per tonne of primary aluminum produced, equivalent to approximately 55 to 60 gigajoules per tonne. This electrolytic phase alone accounts for more than 95 percent of the total energy consumed during primary smelting operations.

Harmful By-Products from Aluminum Manufacturing

Beyond CO₂ emissions, aluminum production generates multiple hazardous by-products of environmental and health significance:

Perfluorocarbon (PFC) Emissions. During operational disturbances within electrolytic cells termed "anode effects"—which occur when aluminum oxide concentration within the molten cryolite bath falls below approximately 1 percent—fluorine from the dissociated cryolite electrolyte reacts with carbon from the consumption of carbon anodes, generating tetrafluoromethane (CF₄) and hexafluoroethane (C₂F₆). These perfluorocarbon compounds possess extraordinarily high global warming potentials: CF₄ exhibits a 100-year global warming potential of approximately 6,500 times that of CO₂, while C₂F₆ exhibits a global warming potential of approximately 9,200 times that of CO₂. Emissions vary substantially between facilities and depend critically upon electrolytic cell technology, anode material specifications, and operational discipline governing alumina feed rate management.

Red Mud (Bauxite Residue). The refining of bauxite ore to aluminum oxide via the Bayer process generates substantial quantities of alkaline industrial waste known as red mud or bauxite residue. For every tonne of alumina produced through this process, approximately 1.0 to 1.5 tonnes of red mud are simultaneously generated as a co-product. Global alumina production of approximately 142 million tonnes annually generates corresponding production of approximately 170 million tonnes of red mud waste. This residue maintains extreme alkalinity (pH 10.5 to 12.5) and contains elevated concentrations of heavy metals, particularly vanadium, which generate environmental contamination and genotoxic effects in biological systems if not properly contained and managed. Improper storage and containment of red mud impoundments poses significant environmental hazards through soil and water contamination.

Sulfur Hexafluoride (SF₆). Aluminum degassing operations employ sulfur hexafluoride gas, a potent greenhouse gas with a 100-year global warming potential exceeding 23,500 times that of carbon dioxide. Although consumption in degassing represents a minor fraction of total SF₆ use globally, it remains a measurable emission source, particularly in aluminum-producing regions with less stringent emission controls.

Accelerating Demand Pressures and Sustainability Constraints

The environmental impact of aluminum production is intensifying as a consequence of multiple simultaneous demand drivers. Rising global population, expanding middle-class consumption in developing economies, and infrastructure urbanization programs—particularly in Asia-Pacific regions—are driving substantial growth in aluminum consumption. Concurrent technological transitions toward electrified transportation (electric vehicles and rail systems), renewable energy infrastructure (solar panel frames and wind turbine nacelles), and heat-intensive manufacturing processes are creating additional demand vectors for lightweight, thermally and electrically conductive aluminum-based solutions.

Current consumption trends reflect the cumulative effects of three primary growth catalysts: (1) transportation sector lightweighting initiatives pursuing fuel efficiency and emissions reduction; (2) rapid urbanization and infrastructure expansion requiring substantial aluminum in building systems, power transmission, and water management applications; and (3) electrification of energy generation and distribution systems necessitating high-conductivity electrical transmission materials. Combined, these demand drivers project global aluminum consumption growth of approximately 24 million metric tons annually through 2035.

For the first time in the industrial history of aluminum production, the sector confronts explicit sustainability constraints—both environmental (carbon budget allocations within 1.5°C climate scenarios) and material resource availability limits (bauxite ore reserve exhaustion timelines). Conventional primary production pathways face increasing carbon pricing mechanisms (including carbon border adjustment mechanisms in the European Union and emerging carbon-linked financing restrictions), creating economic pressure toward secondary production and recycling-based supply chains. Simultaneously, the concentration of primary aluminum production capacity in coal-abundant regions with minimal environmental regulation (predominantly China and India) limits the capacity for rapid grid decarbonization in response to global climate objectives.

This structural tension between rising demand, limited low-carbon primary production capacity, and regulatory carbon constraints establishes aluminum recycling and secondary metallurgical pathways as critical infrastructure for meeting mid-21st-century material demands while maintaining alignment with decarbonization imperatives.