Sustainable High Entropy Steels: A Green Alternative to Conventional High Entropy Alloys

The development of high-entropy alloys (HEAs) enriched conventional metallurgy by showing that metallic systems with five or more principal

elements in near-equiatomic ratios can form relatively stable (actually mostly metastable), solid solutions rather than only intermetallic compounds, an observation that was similar to the

discovery of austenitic Fe-Cr-Ni-Co-Mo stainless steels 100 years before.

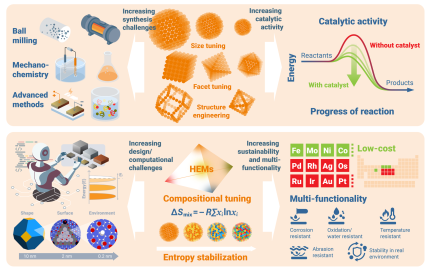

The underlying principle is high configurational entropy (ΔSₘᵢₓ ≈ 1.6 R or higher), which lowers the Gibbs free energy and suppresses ordered phases.

We used this approach and extended this concept toward a Fe-based derivative, termed high-entropy steels (HES). Instead of relying on strictly equiatomic multi-element mixtures, we exploited the flatness of the entropy–composition curve in transition-metal systems, showing that comparable configurational entropy—and hence single-phase stability—can be reached for non-equiatomic but compositionally complex steels.

This means that in our research, we extend the concept of high-entropy alloys (HEAs) toward Fe-based systems that combine the thermodynamic advantages of high configurational entropy with the metallurgical maturity and sustainability of austenitic (stainless) steels.

We found that the entropy–composition function in transition-metal mixtures exhibits a broad and flat plateau, meaning that high configurational entropy can also easily be achieved for non-equiatomic compositions. This insight allows us to design high-entropy steels (HES)—Fe-based alloys that exploit entropy stabilization without resorting to large numbers of expensive elements.

Acta Materialia 59 (2011) 6449 - 6462 TW[...]

PDF-Dokument [1.3 MB]

Alloy Design Strategy for Sustainable High Entropy Steel

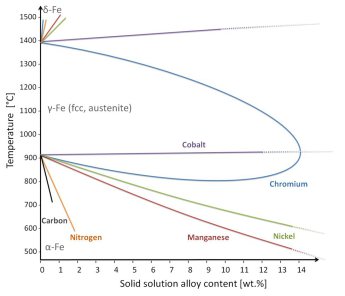

Our work focuses on the Fe–Mn–Al–Si–C system, occasionally simplified to Fe–Mn–Al–C. We deliberately combine:

-

Fe and Mn as principal austenite formers providing a wide fcc (γ) phase field,

-

Al and Si as substitutional elements that reduce density and enhance oxidation resistance, and

-

C as a key interstitial element that stabilizes the fcc matrix and tunes the stacking-fault energy (SFE).

The deliberate use of interstitials, particularly carbon, marks a decisive step beyond classical HEA design. Interstitials not only strengthen the solid solution but also enable deformation mechanisms such as twinning and martensitic transformation (the TWIP and TRIP effects), producing extraordinary strain-hardening and ductility.

nspired by high-entropy alloys (HEAs), this study focuses on designing a new class of high-entropy steels (HESs) by using high configurational entropy to stabilize a single-phase solid solution, particularly exploring the Fe–Mn–Al–Si–C and Fe–Mn–Al–C systems. Unlike conventional HEAs with five or more equiatomic elements, HESs utilize a flat configurational entropy plateau to achieve stable solid solutions with lean, non-equiatomic compositions, positioning them as Fe-based materials where iron still prevails. A key focus is the previously under-addressed role of the interstitial element Carbon (C) in stabilizing and influencing face-centered cubic solid solutions within the HES structure. These high-entropy steels exhibit excellent mechanical properties, including very high

Raabe_et_al-2015-steel_research_internat[...]

PDF-Dokument [1.8 MB]

The alloys we synthesized typically contain Fe ≈ 70 at.%, Mn ≈ 19 at.%, Al ≈ 5 at.%, Si ≈ 5 at.%, C ≈ 1 at.%.

We also used the valence electron concentration (VEC) as an electronic design parameter: values around 8–9 stabilize the fcc phase.

When we include the electrons donated by interstitials such as C or N, our high-entropy steels consistently reach this stability range.

JOM density reduced steels overview 2014[...]

PDF-Dokument [3.7 MB]

Phase Stability and Processing of High Entropy Steels

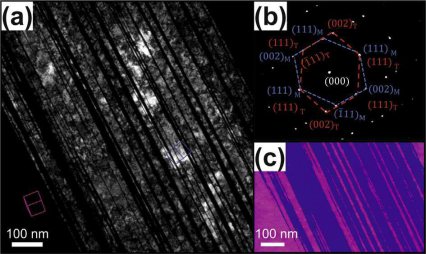

Through thermodynamic analysis and experiments, we showed that non-equiatomic Fe–Mn–Al–Si–C compositions containing 20–30 wt% Mn and 0.5–1.5 wt% C maintain wide fcc solid-solution regions up to 22 wt% Al (≈ 36 at%) without forming intermetallics.

We melted the alloys by vacuum induction under argon, hot-rolled them at 1100 °C, and solution-annealed at 1075–1100 °C to obtain single-phase γ matrices. We emphasized that avoiding intermetallics—not merely maximizing entropy—is the key thermodynamic requirement. Non-equiatomic design enlarges the composition space where entropy stabilization and enthalpy balance yield homogeneous solid solutions.

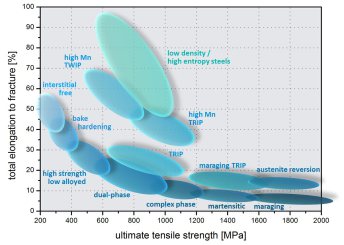

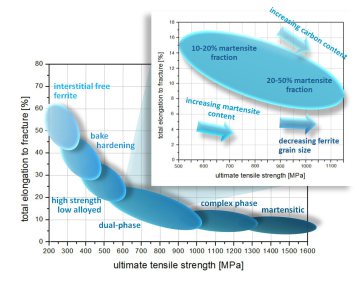

Mechanical Properties and Mechanisms of High Entropy Steels

Our tensile tests from –50 °C to 300 °C revealed exceptional combinations of strength, ductility, and toughness.

| Temperature | UTS (MPa) | Elongation (%) | Dominant mechanism |

|---|---|---|---|

| 25 °C | 900–1000 | 80–100 | TWIP / TRIP balance |

| –50 °C | ≈ 1000 | 60–70 | Deformation-induced martensite (~80 vol%) |

| 300 °C | 600–700 | 40–60 | Dynamic strain aging onset |

Low-C variants (~0.15 wt%) show strong TRIP activity and outstanding cryogenic ductility, while higher-C alloys (> 0.5 wt%) suppress martensite but gain solid-solution strength.

Varying Al content from 0 to 8 wt% increases the yield strength from ≈ 300 MPa to ≈ 500 MPa, with ductility remaining near 100 %. At 11 wt% Al, we reached ~1 GPa yield strength and ~50 % elongation, a combination we attribute to fine κ-carbide precipitation.

Raabe et al Nature 2019 sustainability o[...]

PDF-Dokument [2.2 MB]

Sustainability Rationale behind High Entropy Steels

1. Minimizing Critical-Element Demand

Our alloys eliminate expensive and critical elements such as Co, Ni, and Cr that dominate many HEAs.

Instead, we rely on Fe, Mn, Al, Si, and C—abundant, recyclable, and low-cost.

This reduces the resource and economic footprint by well over 50 % in alloying mass while maintaining comparable or superior performance.

2. Compatibility with Green-Steel Infrastructure

High-entropy steels can be produced and recycled within existing steelmaking routes, whether based on electric-arc

furnaces, hydrogen direct reduction, or scrap recycling.

Unlike many HEAs that require vacuum processing to avoid oxidation, our alloys integrate seamlessly into CO₂-neutral steelmaking pathways, directly supporting

circularity and decarbonization.

3. Lightweight Efficiency

With up to 17 % lower density, our high-entropy steels offer a higher specific strength than conventional steels, providing lightweighting potential for automotive, energy, and aerospace sectors and thus enabling significant in-use CO₂ savings.

4. Entropy through Interstitials

By introducing interstitial elements such as C or N, we achieve entropy engineering without adding new metallic species.

This concept increases configurational and electronic entropy per atom while fine-tuning mechanical response—an elegant, resource-efficient route to property optimization.

5. Long Service Life

The outstanding toughness and cryogenic ductility of our alloys lead to enhanced fatigue and damage tolerance.

This extends component lifetime and reduces life-cycle emissions per ton of material service delivered.

High-entropy materials (HEMs) show inspiring structural and functional properties due to their multi-elemental compositions. However, most HEMs are burdened by cost-, energy-, and carbon- intensive extraction, synthesis, and manufacturing protocols. Recycling and reusing HEMs are challenging because their design relies on high fractions of expensive and limited-supply elements in massive solid solutions. Therefore, we review the basic sustainability aspects of HEMs. Solutions include using feedstock with lower carbon and energy footprints, sustainable primary synthesis routes from minerals, attenuation of the equimolar alloying rule, and a preference for scrap and dumped waste for secondary and tertiary synthesis. The high solubility, compositional flexibility, and chemical robustness of H

sciadv.ads3926.pdf

PDF-Dokument [4.6 MB]

Bidirectional TRIP effect High Entropy A[...]

PDF-Dokument [1.6 MB]