Preparing and transferring atom probe tomography samples under cryogenic and UHV conditions

In this project we devcloped sample transfer instrumentation and integrated protocols for the preparation and atom probe characterization of environmentally-sensitive materials. Ultra-high

vacuum cryogenic suitcases allow specimen transfer between preparation, processing and several imaging platforms without exposure to atmospheric contamination. For expedient transfers, we

installed a fast-docking station equipped with a cryogenic pump upon three systems; two atom probes, a scanning electron microscope / Xe-plasma focused ion beam and a N2-atmosphere glovebox. We

also installed a plasma FIB with a solid-state cooling stage to reduce beam damage and contamination, through reducing chemical activity and with the cryogenic components as passive

cryogenic traps. We demonstrate the efficacy of the new

laboratory protocols by the successful preparation and transfer of two highly contamination and temperature-sensitive samples—water and ice. Analysing pure magnesium atom probe data, we can

show that surface oxidation can be effectively suppressed using an entirely cryogenic protocol (during specimen preparation and during transfer). Starting with the cryogenically-cooled plasma

FIB, we also prepared and transferred frozen ice samples while avoiding significant melting or sublimation, suggesting that we may be able to measure the nanostructure of other

normally-liquid or soft materials. Isolated cryogenic protocols within the N2 glove box demonstrate the absence of ice condensation suggesting that environmental control can commence from

fabrication until atom probe analysis.

Open access: PLOS ONE | https://doi.org/10.1371/journal.pone.0209211 December 21, 2018

Plos One 2018 - The Laplace Suite - atom[...]

PDF-Dokument [2.7 MB]

Can we observed hydrogen and deuterium at atomic scale in high-strength steel?

Observing solute hydrogen (H) in matter is a challenge, yet, quantitative imaging of H at the atomic-scale is critical to understand its influence on the mechanical strength of metallic alloys that results in catastrophic failures of engineering parts and structures through hydrogen embrittlement.

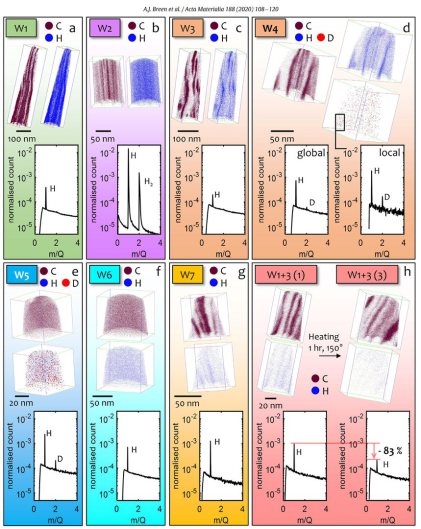

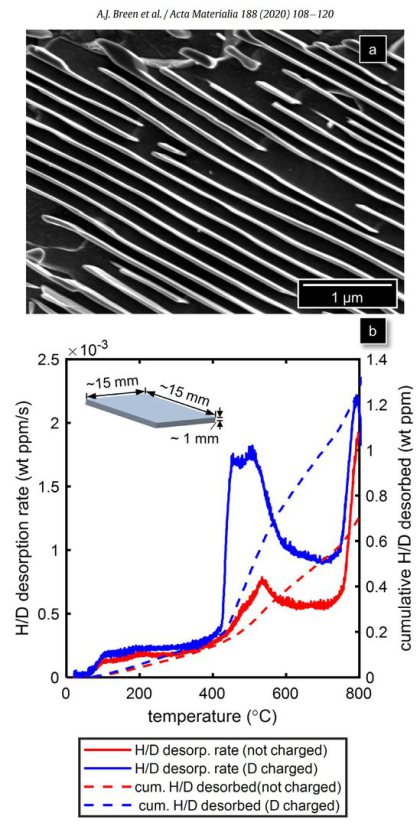

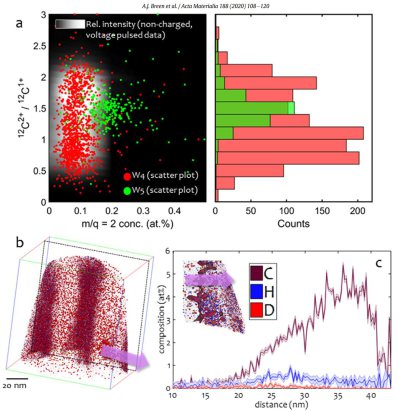

To study these phenomena we conducted APT analysis of hydrogen (H) and deuterium (D) within the nanostructure of an ultra-high strength steel with high resistance to hydrogen embrittlement. Cold

drawn, severely deformed pearlitic steel wires contains cementite decomposed during the pre-deformation of the alloy and ferrite. We find H and D within the decomposed cementite, and at some

interfaces with the surrounding ferrite. To ascertain the origin of the H/D signal obtained in APT, we explored a series of experimental workflows including cryogenic specimen preparation and

cryogenic-vacuum transfer from the preparation into a state-of-the-art atom probe. Our study points to the critical role

of the preparation, i.e. the possible saturation of H-trapping sites during electrochemical polishing, how these can be alleviated by the use of an outgassing treatment, cryogenic preparation

and transfer prior to charging.

Accommodation of large amounts of H in the under-stoichiometric carbide likely explains the resistance of pearlite against hydrogen embrittlement.

Acta Materialia 188 (2020) 108

Acta Materialia 2020 hydrogen deuterium [...]

PDF-Dokument [4.9 MB]

Why is observing hydrogen in alloys important?

H is the lightest and smallest of atoms. It is also ubiquitous. Its pres-

ence within the structure of metals cannot be avoided, partly due to its

high mobility. The interactions between H and metals play an essential

role in the structure-property relationships of engineering alloys.

Hydrogen’s most striking effect on materials is a sudden and often

unpredictable decrease in ductility, toughness, and generally in the

material’s resistance to fatigue-crack propagation known as hydrogen

embrittlement. This phenomenon was discovered as early as 1875 by

Johnson but is still not fully understood to date. A real-life example:

the oil spillage in the Gulf of Mexico in 2012 is attributed to the cata-

strophic failure of connector bolts due to hydrogen embrittlement.

Hydrogen embrittlement mostly affects structural, high-strength

materials that find application in the e.g. automotive, aeronautical, oil

and gas and power generation industries.