Steels for additive manufacturing

Steels in additive manufacturing: relevance of microstructure, alloy design and properties

Why developsteels for additive manufacturing?

The answer relates to the specific features of the process and of the complex thermodynamcis and kinetics of steels:

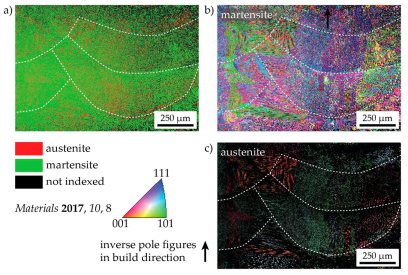

A wide range of steels is nowadays used in Additive Manufacturing (AM). The different matrix microstructure components and phases such as austenite, ferrite, and martensite as well as the various precipitation phases such as intermetallic precipitates and carbides generally eqipp steels with a huge variability in microstructure and properties.

Should steels be developed specifically for additive manufacturing?

Yes: steels have a large variety of microstructure ingredients and phases such as austenite, ferrite, and martensite and many precipitate phases such as intermetallics and carbides. All these microstructure constuents lend steels a huge variability in microstructure and mechanical properties.

These features are influenced substantially through the specific boundary conditions associated with the AM processing, particularly regarding changes in segregation behaviour, the very rapid cooling but also the repeated re-heating experienced by the subsequent layer build-up. Hence, any targetted design of steels suited for AM must involve the effects of these process parameters on the resulting microstructure, precipitation and transformation response and thus the properties.

For which applications are steels the right choice in additive manufacturing ?

Steels are the materials of choice in additive manufacturing for applications where the requirements are:

- Corrosion resistance and general longevity under harsh environmental conditions

- Strength, ductility, hardness, toughness and wear resistance

- Low price

- Unrivalled variety of achievable microstructure features rangingfrom ultra-hard martensite to compliant multiphase compounds

- Functionalities such as ferromagnetism or invar effects.

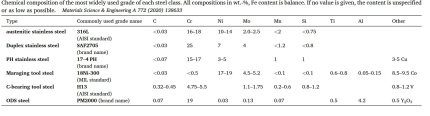

Which types of steels are used in additive manufacturing ?

Good resistance to environmentally very harsh conditions calls for the use stainless steels in additive manufacturing. Consequently, these steels, in

particular AISI 316L/1.4404, are used in a large variety of applications

where the parts to be fabricated are expected to come into contact with

corrosive media at moderate temperatures during service.

Where an overlap of corrosion resistance and increased mechanical strength and hardness (compared to austenitic stainless steels) is required, maraging-

type precipitation-hardened martensitic stainless steel grades are often used (so called PH steel grades such as 17-4PH/1.4542 and 15-5PH/ 1.4545).

This is e.g. the case in marine, power-plant and injection moulding industries.

Good yield strength, high hardness and abrasion resistance are required in the tool and die making industry, calling for tool steels. The key advantage of additive manufacturing in this

application is the ability to manufacture many separate, smoothly curved cooling channels close to the surface contour of e.g. injection moulding tools, leading to an efficient heat removal

and thus an increased productivity and/or lifetime of the tool. The tool steels most used in conventional toolmaking processes contain a significant amount of carbon and are not easy to process,

and thus the most popular choice of tool steel in additive manufacturing processing today are the carbon-free maraging steels, in particular 18Ni-300/1.2709.

The comparably moderate price of stainless steels and their good processability also leads to austenitic stainless steels often being considered a good material for users new to additive

manufacturing.

Besides these main groups of steels, there is a number of other, less frequently studied alloys in use in additive manufacturing.

They include for example martensitic stainless steels, duplex stainless steels, TRIP/TWIP steels and oxide-dispersion strengthened (ODS) steels. Functional application fields for steels such as custom shaped parts for electro-magnetic or invar applications require the use of Fe–Si, Fe–Ni or Fe–Co alloys.

What is the difference between conventional steel design and steel design for additive manufacturing?

The interplay of process parameters such as cooling and reheating and the resultant microstructure applies for both, AM-produced steels just as for conventionally-produced steels.

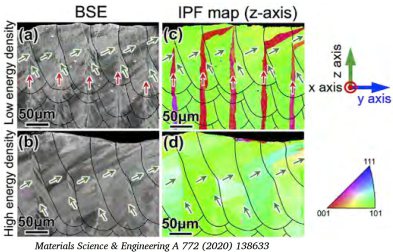

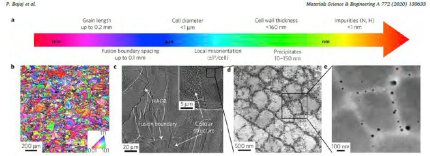

However, steels are subjected during AM processing to time-temperature profiles which are very different from the ones encountered in conventional process routes, and hence the resulting

microstructures differ strongly as well. This

includes a very fine and highly morphologically and crystallographically textured microstructure as a result of high solidification rates as well as non-equilibrium phases in the as-processed

state. Such a microstructure, in turn, necessitates additional or adapted post-AM heat treatments and alloy design adjustments. In our projects, we study the different kinds of steels in use in

fusion-based AM processes and present their microstructures, their mechanical and corrosion properties, their heat treatments and their intended applications.

This includes austenitic, duplex, martensitic and precipitation-hardening stainless steels, TRIP/TWIP steels, maraging and carbon-bearing tool steels and ODS steels.

From this reserach we are capable of identifying areas with missing information in the literature and assess which properties of AM steels exceed those of conventionally-produced ones, or,

conversely, which properties fall behind. We close our review with a short summary of iron-base alloys with functional

properties and their application perspectives in Additive Manufacturing.

Why use steels in additive manufacturing?

Steels are the suited material choice in additive manufacturing and 3D printing for applications where the following requirements are requested:

High elastic stiffness

Corrosion resistance and general longevity under harsh environmental conditions

Strength, ductility, hardness, toughness and wear resistance

Low price and wide abundance

Unrivalled variety of achievable microstructure features ranging

from ultra-hard martensite to compliant multiphase compounds,

and/or

Functionalities such as ferromagnetism or invar effects.

Mat Sc Engin 2019 Steels in additive man[...]

PDF-Dokument [1.9 MB]

Acta Mater 2017 Additive Manufacturing M[...]

PDF-Dokument [2.4 MB]

Materials 2017-10-8 Laser Additive Manuf[...]

PDF-Dokument [2.7 MB]

Jägle et al. (2014) 29 17 Laser additive[...]

PDF-Dokument [489.4 KB]