Dramatic events caused by materials failure

Developing strong, damage-tolerant, and functional metallic materials forms the backbone for multiple industrial innovations in the fields of energy, transportation, health, building infrastructure, safety, machinery, and industrial infrastructure.

Here specifically advanced steels occupy absolute key roles. Examples are advanced Fe-Cr steels for high-temperature applications in emission-reduced turbines; weight reduced and ultra high strength Fe-Mn steels for light-weight and yet passenger-protecting mobility; soft magnetic Fe-Si steels, semi-amorphous steels, and iron-based metallic glasses for low-loss electrical motors and wind energy generators; radiation resistant steels for nuclear and fusion power plants; or Fe-Cr-Ni stainless steel tubes for direct solar thermal power plants.

The fact that new metallic alloys are often 'hidden' behind the final product sometimes conceals the truth that without permanent innovation in this field many advanced industrial products would be impossible to realize. Awareness of the profound recent advances in metallic research sometimes suffers a bit from its engineering success: Although metals and specifically steels are key components in many zero-damage-tolerance safety design parts (planes, trains, cars, bridges, wind mills, power plants, etc.) they very rarely fail, hence, awareness of the high relevance of metals is not as ubiquitous as the products that are made of it. This is surprising when considering that the annual steel production alone exceeds 1.4 Billion tons and that most high-performance metals are complex nanostructured materials. Here we shows some tragic examples, what can happen, if metallic alloys fail.

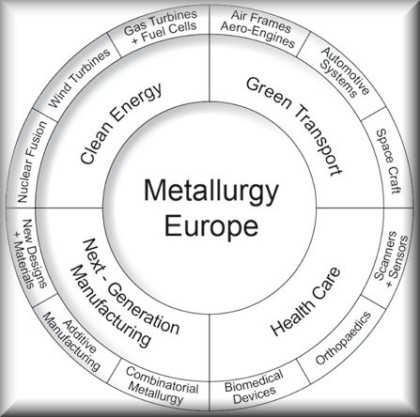

Metallurgy Europe – A Renaissance Programme for 2012-2022

Read the latest recommenadations of the Materials Science and Engineering Expert Committee (MatSEEC):

Metallurgy Europe – A Renaissance Programme for 2012-2022

Science Position Paper

Metallurgy-Europe_2012.pdf

PDF-Dokument [3.1 MB]