Digital Image Correlation (DIC) for local strain measurement in polycrystalline and inhomogeneous materials

Introduction to Digital Image Correlation (DIC)

Deformed materials usually reveal a nonuniform distribution of plastic strain. In polycrystals this phenomenon is attributed to the anisotropic nature of crystal slip, to the non-isotropic interaction of the different lattice defects, and to the influence of macroscopic boundary conditions in terms of geometrical and kinematoc constraints and friction.

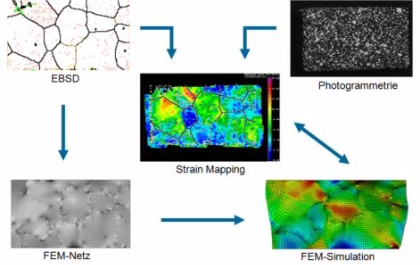

Digital image correlation, abbreviated as DIC, is an experimental approach for the investigation of such phenomena at the grain scale. The technique is characterized by the joint application of photogrametry and microtructure determination. It aims at mapping both, mechanical and microstructural changes during elastoplastic deformation of complex and inhomogeneous materials.

How does Digital Image Correlation work?

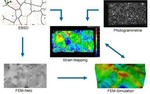

Photogrametry or digital image correlation is a method to determine the spatial distribution of microstrains at the sample surface by measurement of changes in the three dimensional plastic displacement field during a deformation experiment. The technique consists in employing a pattern recognition algorithm for the detection of changes in the gray scale distribution of surface patterns occurring during elastic-plastic straining. The microstructure of the specimens is for instance determined by analysis of electron back scattering patterns obtained in a scanning electron microscope.

Details about Digital Image Correlation for probing polycrystal mechanics

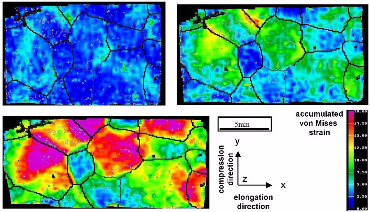

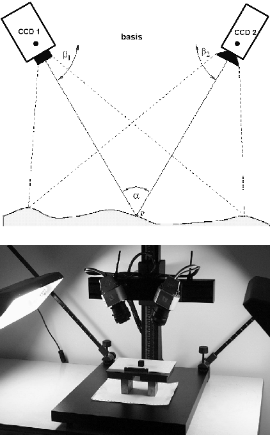

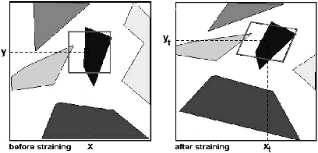

The determination of plastic displacement fields and the subsequent calculation of some tensor components of the plastic strain field after a defined external deformation step can be conducted by a photogrametric procedure which is also referred to as Digital Image Correlation (DIC). This is a digital image analysis method which is based on the recognition of geometrical changes in the gray scale distribution of surface patterns before and after straining. Both, the natural characteristics of an unprepared sample surface or an artificial quasi-stochastic color spray applied to a polished surface may serve as input pattern. In order to measure the three dimensional surface coordinates digital stereo pair images of the sample were acquired using two high resolution CCD cameras.

Pattern recognition is carried out by a digital image processing procedure which maps a rectangular grid onto the image. The grid points are characterized by three dimensional coordinates and by the gray scale distribution in their proximity. After straining the pattern is again recognized based on the assumption that the gray scale distribution around a certain coordinate remains constant during straining. From the change in border coordinates containing the correct initial gray scale distribution around the grid point the three dimensional displacement gradient tensor field is determined at each grid point. These data serve as input for deriving the surface components of the local strain tensor. The strain tensor is used in the definition as the first order approximation of the standard polar decomposition of the displacement gradient tensor. In the method used in our group typcially a fine white color spray is applied to the polished surface of an undeformed sample. The resulting gray scale pattern on the surface of the specimen is then recorded and reference coordinates for the different experimental methods (microtexture, metallography, microstrain determination) are fixed on the sample surface. These surface markers enable us to identify the same sample areas under the different experimental environments ensuring a one-to-one correspondence of the different results.

The specimen is then deformed for instance using a tensile testing or a channel die set-up. After each deformation step the surface gray scale pattern is acquired and the displacement gradient field as well as the strain distribution are calculated. It must be underlined in this context that the photogrametric method works without any additional artificial regular grid on the sample surface. The displacement gradient field is derived exclusively from changes in the border coordinates for a gray scale distribution at each coordinate. The spatial resolution of the method is therefore independent of some external grid size but is of the order of the respective optical setup.

Example and Literature about Digital Image Correlation (DIC)

Z. Zhao,M. Ramesh,D. Raabe, A.M. Cuitino, R. Radovitzky

International Journal of Plasticity 24 (2008) 2278-2297

Investigation of three-dimensional aspects of grain-scale plastic surface deformation of an aluminum oligocrystal

Intern Journ Plast 24 (2008) 2278 grain [...]

PDF-Dokument [931.6 KB]

Annual Review of Materials Research

Vol. 45: 391-431 (July 2015)

DOI: 10.1146/annurev-matsci-070214-021103

An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design

Annu. Rev. Mater. Res. 2015. (45) 391-43[...]

PDF-Dokument [4.2 MB]

Dual-phase (DP) steel is the flagship of advanced high-strength steels, which

were the first among various candidate alloy systems to find application in

weight-reduced automotive components. On the one hand, this is a metal-

lurgical success story:Lean alloying and simple thermomechanical treatment

enable use of less material to accomplish more performance while comply-

ing with demanding environmental and economic constraints. On the other

hand, the enormous literature onDP steels demonstrates the immense com-

plexity ofmicrostructure physics inmultiphase alloys: Roughly 50 years after

the first reports on ferrite-martensite steels, there are still various open sci-

entific questions. Fortunately, the last decades witnessed enormous advances

in the development of enabling experimental and simulation techniques, sig-

nificantly improving the understanding of DP steels. This review provides

a detailed account of these improvements, focusing specifically on (a) mi-

crostructure evolution during processing, (b) experimental characterization

of micromechanical behavior, and (c) the simulation of mechanical behavior,

to highlight the critical unresolved issues and to guide future research efforts.

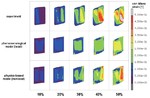

The mechanical response of multiphase alloys is governed by the microscopic strain and stress partitioning behavior among microstructural constituents. However, due to limitations in the characterization of the partitioning that takes place at the submicron scale, microstructure optimization of such alloys is typically based on evaluating the averaged response, referring to, for example, macroscopic stress-strain curves. Here, a novel experimental–numerical methodology is introduced to strengthen the integrated understanding of the microstructure and mechanical properties of these alloys, enabling joint analyses of deformation-induced evolution of the microstructure,

and the strain and stress distribution therein, down to submicron resolution. From the experiments, deformation-induced ev

Acta Materialia 2014 CPFEM ICME DP steel[...]

PDF-Dokument [6.6 MB]

International Journal of Plasticity 63 (2014) 198-210: Ferritic–martensitic dual phase steels (DP steels) deform heterogeneously with strong strain and stress partitioning at the micro-scale. Such heterogeneity leads in turn to a spatially heterogeneous damage distribution, and thus, plays an important role in the process of damage inheritance and fracture. To understand and improve DP steels, it is important to identify connections between the observed strain and damage heterogeneity and the underlying microstructural parameters, e.g. ferrite grain size, martensite distribution, martensite fraction, etc. Here we pursue this by conducting in-situ deformation experiments on two different DP steels employing two different microscopic-digital image correlation (lDIC) techniques to achieve m

Intern J Plasticity 2014 Diehl Tasan str[...]

PDF-Dokument [1.9 MB]

High resolution in situ mapping of microstrain and microstructure evolution reveals damage resistance criteria in dual phase steels

Acta Materialia 96 (2015) 399-409

D. Yan, C. C. Tasan, D. Raabe

Acta Materialia 96 (2015) 399 Yan Tasan [...]

PDF-Dokument [1.7 MB]

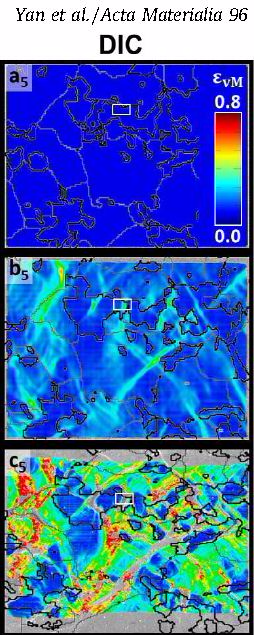

Microstructures of multi-phase alloys undergo morphological and crystallographic changes upon deformation, corresponding to the associated microstructural strain fields. The multiple length

and time scales involved therein create immense complexity, especially when microstructural damage

mechanisms are also activated. An understanding of the relationship between microstructure and damage initiation can often not be achieved by post-mortem microstructural characterization

alone. Here, we present a novel multi-probe analysis approach. It couples various scanning electron microscopy methods to microscopic-digital image correlation (l-DIC), to overcome various

challenges associated with concurrent mapping of the deforming microstructure along with the associated microstrain fields. For this purpose a contrast- and resolution-optimized l-DIC

patterning method and a selective pattern/microstructure imaging strategy were developed. They jointly enable imaging of (i)

microstructure-independent pattern maps and (ii) pattern-independent microstructure maps. We apply this approach here to the study of damage nucleation in ferrite/martensite dual-phase (DP)

steel. The analyses provide four specific design guidelines for developing damage-resistant DP steels.

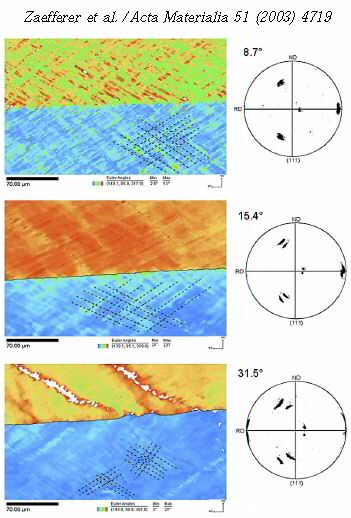

Zaefferer, S., Kuo, J.-C., Zhao, Z., Winning, M., Raabe, D.

On the influence of the grain boundary misorientation on the plastic deformation of aluminum bicrystals

(2003) Acta Materialia, 51 (16), pp. 4719-4735.

Acta Materialia 51 (2003) 4719 Bicrystal[...]

PDF-Dokument [641.4 KB]

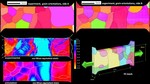

This is an experimental and theoretical study on deformed aluminum bicrystals. We aim at better understanding the role of grain boundaries of different misorientations during plastic deformation. Grain boundaries act as

obstacles to dislocation motion during deformation entailing an increase in yield strength with decreasing grain size as expressed by the Hall–Petch relation. The mechanical effect

of a grain boundary depends on its misorientation. Small angle grain boundaries (with misorientations of up to 15–20°) are weak obstacles to the plastic flow when compared to

large angle grain boundaries because they

can be penetrated by dislocations which continue their glide path in the neighboring crystal. However, since small angle grain boundaries themselves

consist of dislocations, the interaction with mobile dislocations may gradually change their structure and

misorientation during plastic straining. In order to study these effects in quantitative detail and derive from them an improved understanding of inter- and intragranular strain heterogeneity inherent to polycrystal plasticity [1–4], we investigate in this work a set of bicrystals with different well defined grain boundaries during deformation.

More specific Aluminum bicrystals with symmetric 1 1 2 tilt boundaries and misorientations of 8.7° (small angle), 15.4° (transition), and 31.5° (large angle) were deformed in a channel die experiment in order to study the influence of

misorientation on the deformation at grain boundaries. Samples were characterized by strain measurements and microtexture mappings. The experiments were compared to crystal plasticity finite

element simulations. We studied strain heterogeneity at the macroscopic and at the microscopic level. Even macroscopically homogeneous areas showed microscopic heterogeneity in the form of

bands of different sets of glide systems. We observed clear effects of the grain boundary misorientation on the deformation kinematics close to the boundaries. The 8.7° grain boundary did

not show any orientation change which was interpreted in terms of free dislocation penetration. In contrast, the 15.4° and

31.5° bicrystals showed orientation changes which were attributed to dislocation pile-ups.

Materials Science and Engineering A336 (2002) 81-87

Experimental investigation of plastic grain interaction

M. Sachtleber, Z. Zhao, D. Raabe

Mater Sc Eng A336 (2002) 81 investigatio[...]

PDF-Dokument [672.8 KB]

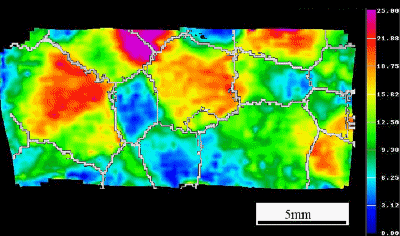

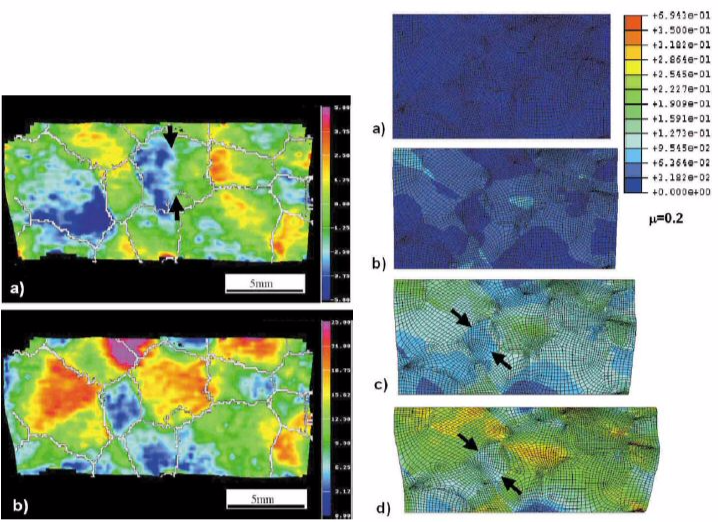

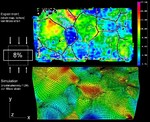

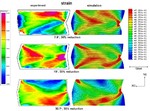

Aluminum polycrystals with columnar coarse grains are plastically compressed in a channel die. The spatial distribution of the accumulated plastic surface strains is determined by measuring the displacement fields using photogrametry. For this purpose digital stereological image pairs of the sample surface are taken at the beginning and after each deformation step. The

displacement field is derived from them by applying an image analysis method based on pattern recognition to the data before and after straining. The three components of the plastic

displacement vector field are used to derive the surface portion of the plastic strain tensor field. The microtexture of the specimens is determined by the analysis of electron backscattering

patterns

obtained in a scanning electron microscope. The experiments are interpreted by comparing them to the corresponding crystal plasticity finite element simulations.

Raabe et al. Acta Materialia 51 (2003) 1539-1560

Grain-scale micromechanics of polycrystal surfaces during plastic straining

Acta Materialia 51 (2003) 1539 grain mec[...]

PDF-Dokument [1.8 MB]

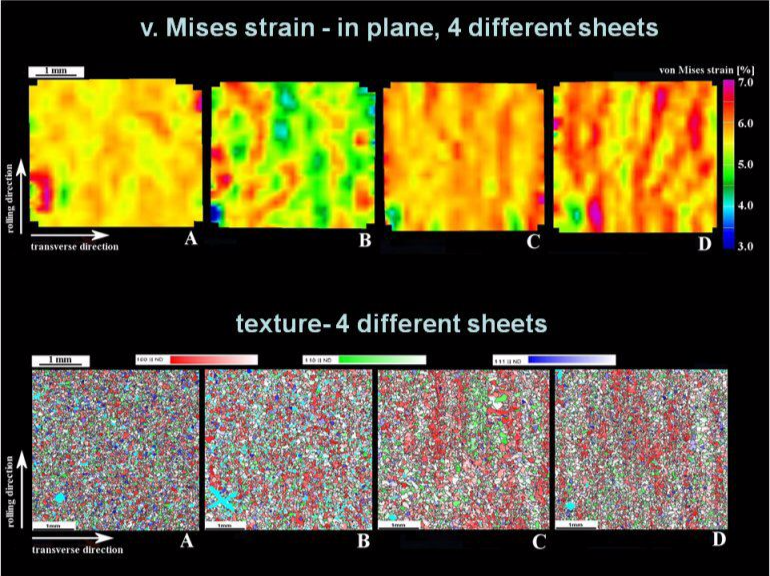

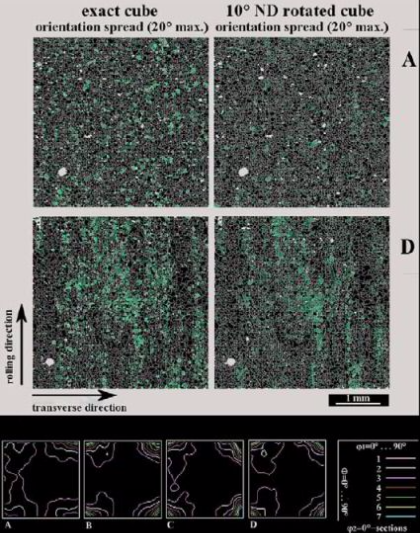

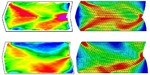

Here we study grain-scale micromechanics of polycrystal surfaces during plastic straining. We use Al–Mg–Si sheets (alloy AA6022) as model material. The work aims at understanding the relationship between microstrain heterogeneity and surface roughness in plastically strained polycrystals in terms of the surface and through-thickness microstructure. Experiments were conducted on polycrystals with identical composition but different processing and microstructures. We performed tensile and bending tests on sheet samples cut in transverse and rolling directions. We investigated the plastic surface microstrains (photogrametry), surface topography (confocal microscopy), particle distribution (metallography, SEM), microtexture (EBSD), and grain size distribution (EBSD) in the same sample regions. We also conducted in-situ straining experiments where the microtexture, surface topography, and stress–strain behavior were simultaneously determined. The results reveal a relationship between the heterogeneity of plastic surface microstrains, roughness, and microstructure. In particular a correlation could be established between microstrains and banded microtexture components (Cube, Goss, {111}[uvw]). Grain-scale roughening in homophase alloys can be grouped into orange peel and banding phenomena. The former are characterized by out-of-plane displacement fields (negative or positive), which roughly map the grain shape of the material. The latter are commonly referred to as ridging or roping phenomena. They occur in the form of banded surface undulations which typically extend along the rolling direction of the material. They have a transverse extension above the grain size

This paper reviews continuum-based variational formulations for describing the elastic–plastic deformation of anisotropic heterogeneous crystalline matter. These approaches, commonly referred to as

Crystal Plasticity Finite Element Overvi[...]

PDF-Dokument [8.3 MB]

This is a study of plastic strain localization, surface roughening and of the origin of these phenomena in polycrystals. An oligocrystal aluminum sample with a single quasi-2D layer of coarse grains i

Int J Plast 24 (2008) 2278 CPFEM dogbone[...]

PDF-Dokument [2.7 MB]

A polycrystalline aluminum sample with a quasi-2D single layer of coarse grains is plastically deformed in a channel die plane strain set-up at ambient temperature and low strain rate. The microtextur

Acta-mater-49-2001-micromechanics.pdf

PDF-Dokument [471.6 KB]

Local deforrmation analysis in biological materials: Digital Image Correlation (DIC) for biological specimens

In order to record the local deformation patterns during deformation tests conducted on biological materials the same methods as outlined above apply.

In the cases shown in the papers below typically two digital cameras, mounted perpendicular to a tensile test rack, are used for taking images enabling the three-dimensional localization of each

point on the sample surface. The cameras (CCD-1300: VDS Vosskühler GmbH, 49084 Osnabrück, Germany) feature a resolution of up to 1300 dpi and were equipped with lenses of 50 mm focal length and a

maximum aperture of 2.8 (Schneider-Kreuznach, 55543 Bad Kreuznach, Germany). The camera set-up is controlled by the ARAMIS system (GOM - Gesellschaft für Optische Messtechnik mbH, 38106 Braunschweig,

Germany). Digital pictures were recorded every 1 s which corresponds to an elongation of 6 micrometer.

Journal of Structural Biology 161 (2008) 120-132

Influence of microstructure on deformation anisotropy of mineralized cuticle from the lobster Homarus americanus

C. Sachs, H. Fabritius, D. Raabe

Journal of Structural Biology 161 (2008)[...]

PDF-Dokument [2.8 MB]

Biological materials often combine various mechanical principles of construction and are simultaneously multifunctional according to the requirements of the organism. A major design principle in nature is the hierarchical organization which is perfectly implemented in the exoskeletons of Arthropoda or other mechanically relevant structures like the bones of vertebrates and the shells of mollusks. The exoskeleton is formed by the cuticle of arthropods and consists of chitin and various proteins. Most members of the Crustacea, which represent an important group inside the Arthropoda, implement variable amounts of nanoscopic crystalline or amorphous calcium carbonate particles to harden the exoskeleton in the rigid body parts like the chelipeds in contrast to the flexible parts like joint membranes (Roer and Dillaman, 1984). The American lobster Homarus americanus is a large sized crustacean. Its body can be divided into the head (cephalon), the thorax, and the tail (abdomen). The first three pairs of walking legs which are attached to the thorax end in true pincers (Factor, 1995). Characteristically, the first pair is enlarged to massive and flattened claws which are referred to as crusher claw and pincher claw according to their biological function (Travis, 1963; Vernberg and Vernberg, 1983). Arthropod cuticle consists of the apical epicuticle and the inner procuticle (Hadley, 1986). While the epicuticle as thin waxy layer provides a permeability barrier to the environment, the procuticle which can be subdivided into the exocuticle and the endocuticle is the mechanically relevant layer. Both sublayers are made up of mineralized chitin–protein fibers forming a twisted plywood structure with different rotation angles, which leads to different lamella thicknesses in the exo- and the endocuticle (Giraud-Guille, 1998). Due to the mechanical loads occurring in the two claws, particularly the thickness of the endocuticle is strongly increased to the millimeter range whereas the thickness of the exocuticle remains constant at values of about 200 um. Epi- and procuticle represent the highest level in the hierarchical organization of the lobster’s exoskeleton (Fig. 1a, I). The next lower level is the twisted plywood- or Bouligand structure (Fig. 1a, II and b) which is formed by stacking planes of parallel arranged mineralized chitin–protein fibers (Fig. 1a, III) and rotating them around the normal axis of the cuticle (Bouligand, 1970; Giraud-Guille, 1984; Weiner and Addadi, 1997). The distance in which a rotation of 180 is completed can be defined as the stacking height of the twisted plywood structure (Fig. 1b). The mineralized chitin–protein fibers (Fig. 1a, IV) have diameters between 50 and 250 nm and consist of clustered chitin–protein nanofibrils interspersed with nanoscopic particles of amorphous or crystalline calcium carbonate. The nanofibrils themselves are a-chitin crystals wrapped in proteins (Fig. 1a, V) with diameters of about 2–5 nm and lengths of about 300 nm. They contain 18–25 chains (Fig. 1a, VI) of chitin molecules (Fig. 1a, VII) arranged in an anti-parallel fashion (Giraud-Guille, 1990; Andersen, 1999). Besides the twisted plywood structure a second design principle can be found in the lobster cuticle. Due to a well-developed pore canal system a honeycomb-like structure is generated as numerous canals penetrate the cuticle perpendicular to its surface (Fig. 1b and c). Each pore canal contains a long, soft, and probably flexible tube which has an elliptical-like outline with the long axis of the ellipse parallel to the fiber orientation in each plane (Fig. 1c). Due to the rotation of the twisted plywood structure the outer shape of each tube resembles a twisted ribbon. Similar pore canals are also present in the cuticle of crabs like Carcinus maenas (Compe re and Goffinet, 1987).

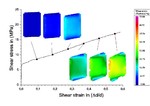

The combination of a honeycomb-like structure and a twisted plywood structure with tightly connected lamellae should lead to remarkable mechanical properties (Sachs et al., 2006a) and an anisotropic deformation behavior. To investigate the elastic–plastic deformation behavior and its anisotropy at a global and a local scale we performed compression tests combined with digital image correlation (Sachs et al., 2006b) as well as shear tests on endocuticle samples extracted from the claws. A detailed analysis of the deformed microstructure revealed the underlying deformation mechanisms in the examined cuticle parts of the lobster H. americanus.

In this specific paper the exoskeleton of the American lobster Homarus americanus is studied: It is a hierarchically organized nano-composite material consisting of organic chitin–protein fibers associated with inorganic calcium carbonate. The presence of a well-developed and periodically arranged pore canal system leads to a honeycomb-like structure. The concomitant presence of the twisted plywood arrangement of the mineralized chitin–protein fibers alters the elastic properties, the deformation behavior, and fracture behavior compared to classical honeycomb structures. By performing compression tests in various directions of the cuticle we examined the anisotropic elastic–plastic deformation

and fracture behavior of mineralized parts of the exoskeleton. By applying digital image correlation during compression testing, the evolution of the elastic–plastic deformation at the microscopic scale was observed with high resolution and simultaneously global stress and strain data were acquired. Shear tests were performed in order to determine the fracture energy for different shear planes and directions. The investigation of the microstructure after plastic deformation revealed the underlying deformation mechanisms of lobster endocuticle from the claws under different loading conditions. For evaluating the effect of hydration the samples were tested both in the dry and in the wet state.

This study presents a novel experimental approach to the characterization of the deformation of a mineralized biological composite using arthropod cuticle as a model material. By performing tensile te

Journal of Structural Biology 155 (2006)[...]

PDF-Dokument [1.3 MB]

Adv. Mater. 21 (2009) 391–400 overview c[...]

PDF-Dokument [1.3 MB]