Dual phase high entropy alloy

What are dual phase high entropy alloys ?

Dual phase high entropy alloys are metallurgical materials which consist of a higher number of elemental components (4 or more) with the aim to form massive solid solutions exploiting the associated enhanced configurational entropy which stabilises them.

Different from the original high entropy alloy concept such dual phase high entropy alloys are flexible in the specific number of components used and also do not need to utilize equal compositions for each of the elements. Instead the dual phase high entropy alloys can be designed by using non-equimolar atomic mixtures. The second most important difference to the original high entropy alloy concept is that the dual phase high entropy alloys consist of two or more solid solution phases with different crystal structure, where all of these phases are massive solid solutions following the original high entropy alloy concept.

Acta Materialia 136 (2017) 262-270;

Here we introduce a new class of high-entropy alloys (HEAs), i.e., quinary (five-component) dual-phase (DP) HEAs revealing transformation-induced plasticity (TRIP), designed by using a quantum mechanically based and experimentally validated approach.

Acta Materialia 2017 Ab initio design qu[...]

PDF-Dokument [4.9 MB]

The mechanical properties of dual phase high entropy alloys can be improved by friction stir procesing

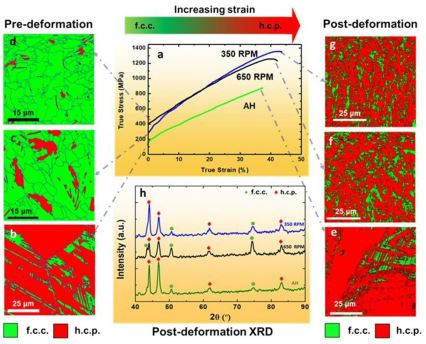

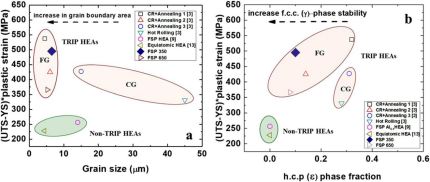

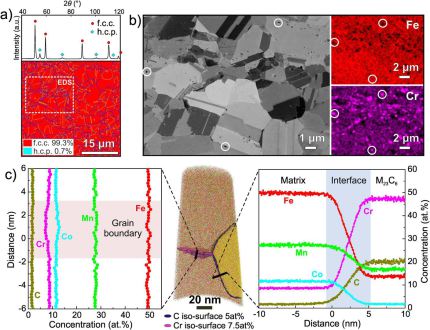

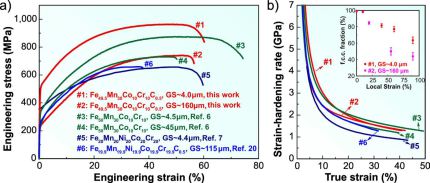

Dual phase high-entropy alloys (HEAs) exhibit an extraordinary combination of mechanical properties. In this project we show how an even stronger and yet very ductile non-equiatomic dual phase HEA

can be obtained after friction stir processing. For this purpose a transformation-induced plasticity (TRIP) assisted

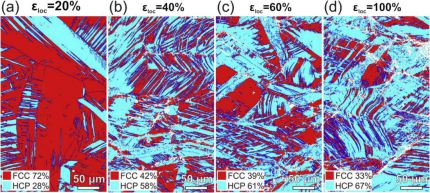

HEA with composition Fe50Mn30Co10Cr10 (at.%) was severely deformed by friction stir processing and evaluated for its microstructure-mechanical property relationships. The friction stir

processing-engineered microstructure of the TRIP dual phase HEA exhibited a substantially smaller grain size, and optimized fractions of face-centered cubic (f.c.c., γ) and hexagonal

close-packed (h.c.p., ε) phases, as compared to the as-homogenized reference dual phase high-entropy alloy. This results in synergistic strengthening via TRIP, grain boundary strengthening, and

effective strain partitioning between the γ and ε phases during deformation, thus leading to enhanced strength and ductility of the TRIP-assisted dual-phase HEA engineered via friction stir

processing.

SCiENTiFiC REPOrTS | 7: 16167 | DOI:10.1038/s41598-017-16509-9

Scientific Reports 7-16167 Friction Stir[...]

PDF-Dokument [1.7 MB]

What is the influence of interstitial atoms in dual phase and single phase high-entropy alloys ?

Scientific Reports | 7:40704 | DOI: 10.1038/srep40704

Li_et_al-2017-Scientific_Reports interst[...]

PDF-Dokument [3.0 MB]

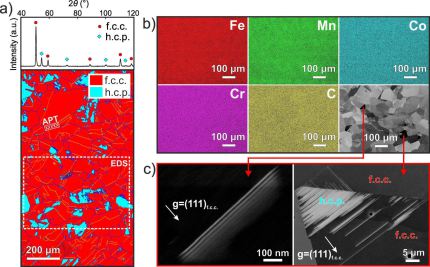

In this project we are concerned with the role that interstitial atoms play in dual phase and single phase high-entropy alloys.

Generally high-entropy alloys (HEAs) consisting of multiple principle elements provide an avenue for realizing exceptional mechanical, physical and chemical properties. In this project we pursued a novel strategy for designing a new class of HEAs incorporating the additional interstitial element carbon. This results in joint activation of twinning- and transformation-induced plasticity (TWIP and TRIP) by tuning the matrix phase’s instability in a metastable TRIP-assisted dual-phase HEA. Besides TWIP and TRIP, such alloys benefit from massive substitutional and interstitial solid solution strengthening as well as from the

composite effect associated with its dual-phase structure. Nanosize particle formation and grain size reduction are also utilized. The new interstitial TWIP-TRIP-HEA thus unifies all metallic

strengthening mechanisms in one material, leading to twice the tensile strength compared to a single-phase HEA with

similar composition, yet, at identical ductility.

Frontiers Materials 2018 TRIP-Assisted D[...]

PDF-Dokument [5.5 MB]