Electrical steels - Iron-Silicon Transformer Steels

Overview of soft ferromagnetic materials

Soft ferromagnetic materials are those materials that can be easily magnetised and demagnetised. They typically have intrinsic coercivity values below 1000 Am-1. Soft

ferromagnetic materials are primarily used to enhance and/or channel the flux produced by an electric current. The main parameter, often used as a figure of merit for soft magnetic

materials, is the relative permeability ( mr, where mr = B/moH), which is a measure of how readily the material responds to the applied magnetic field. The other main parameters of interest

are the coercivity, the saturation magnetisation and the electrical conductivity.

The types of applications for soft magnetic materials fall into two main categories: AC and DC. In DC applications the material is magnetised in order to perform an operation and

then demagnetised at the conclusion of the operation, e.g. an electromagnet on a crane at a scrap yard will be switched on to attract the scrap steel and then switched off to drop the steel. In AC

applications the material will be continuously cycled from being magnetised in one direction to the other, throughout the period of operation, e.g. a power supply transformer. A high permeability

will be desirable for each type of application but the significance of the other properties varies.

For DC applications the main consideration for material selection is most likely to be the permeability. This would be the case, for example, in shielding applications where the flux must be

channelled through the material. Where the material is used to generate a magnetic field or to create a force then the saturation magnetisation may also be significant.

What are the main contributions to energy losses in soft magentic alloys?

For AC applications the important consideration is how much energy is lost in the system as the material is cycled around its hysteresis loop. The energy loss can originate from three main different sources:

a) hysteresis loss, which is related to the area contained within the hysteresis loop;

b) eddy current loss, which is related to the generation of electric currents in the magnetic material and the associated resistive losses and

c) anomalous loss, which is related to the movement of domain walls within the material.

The magnetic hysteresis losses can be reduced by the reduction of the intrinsic coercivity, with a consequent reduction in the area contained within the hysteresis loop.

Eddy current losses can be reduced by decreasing the electrical conductivity of the material and by laminating the material, which has an influence on overall conductivity and is important because of

skin effects at higher frequency. Finally, the anomalous losses can be reduced by having a completely homogeneous material, within which there will be no hindrance to the motion of domain

walls.

Tyipcal soft magnetic materials are Iron-Silicon Alloys (electrical steels), amorphous and nano-crystalline alloys, and Nickel-Iron Alloys.

What is silicon steel (electrical steel) ?

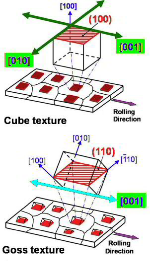

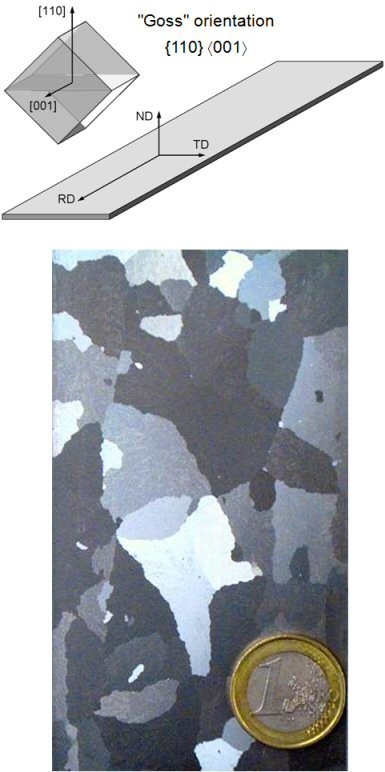

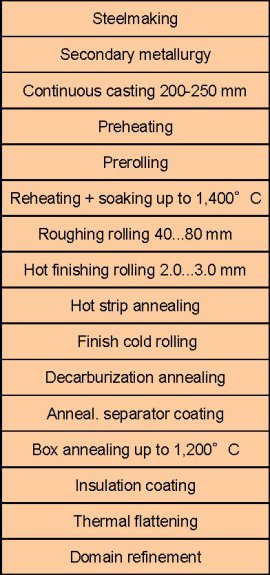

Silicon steel is a soft magnetic material that is used in electrical power transformers, motors and generators. It has a high silicon content of about 3.2 mass %, which increases the electrical resistivity of iron and, therefore, reduces eddy current losses. Grain-oriented silicon steel that is used for non-rotating applications, i.e. transformers, is characterised by a strong preferred crystallographic orientation. In iron the easiest directions of magnetisation are the <001> crystal directions. In grain-oriented silicon steel the Goss orientation, i.e. the {110}<001> orientation , is technologically realised to minimise magnetic losses in electrical transformers.

Texture and microstructure control in electrical steels

Grain-oriented silicon steel (Fe-Si steel; transformer steel; electrical steel) is a soft magnetic polycrystalline metallic alloy that is used as core material in electrical transformer cores and electrical motors.

In the power industry electrical voltage is almost always AC and has a rather low frequency, namely, 50-60 Hz. At these frequencies electrical eddy currents are generated in the transformer core. Alloying the Fe with Si has a large marked effect on the electric resistivity of the material, with an increase of a factor of 4 for 3wt%Si. Silicon also has the effect of reducing the magnetostriction (i.e. length change on magnetisation) and the magnetocrystalline anisotropy. In addition, the material is used in the form of laminations, typically 0.3 to 0.7mm thick. The addition of too much silicon makes the material extremely brittle and difficult to produce, giving a practical limitation of 4wt% to the amount of Si that can be added. Recently, a technique has been developed to produce laminations with >6wt% Si, by a SiCl4 chemical vapour deposition treatment to enrich the laminations with Si after forming the laminations. Typically most commercially available electrical steels will contain between 3 and 4 wt% Si.

Texture and microstructure control for electrical transformer applications

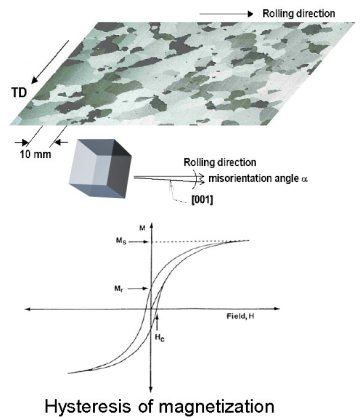

For transformer applications the flux lies predominantly in the length of the laminations and therefore it is desirable to enhance the permeability in this direction. This is achieved by various hot and cold rolling stages to produce textured sheets, known as grain-oriented silicon-steel, with the [001] direction in the length of the lamination. The <001> type crystal directions are the easy directions of magnetisation and hence the permeability is greater. Therefore, electrical steels are characterized by a pronounced Goss texture, i.e. a (110)<001> preferred crystal orientation.

Relevance of the Goss texture for electrical steels in case of transformer applications

Since the <001> crystallographic directions are the ones with the easiest directions of magnetisation and hence largest permeability electrical steels suited for transformer aplications are characterized by a pronounced Goss texture, i.e. a (110)<001> preferred crystal orientation relative to the main magnetic design direction of the transformer.

How is the Goss texture formed in electrical steels ?

Most soft magentic electrical steels are characterized by a pronounced Goss texture, i.e. a (110)<001> preferred crystal orientation. This sharp texture develops due to a discontinuous or abnormal Goss grain growth during a high-temperature annealing at the end of the production process. Although it is a matter of intensive basic and applied research since more than 50 years, there is no general agreement on the origin of preferred growth of the Goss grains. It is known, however, that the inheritance of Goss orientation from early production stages plays an important role. Therefore, intense research is conducted intending to betetr understand the evolution of the Goss orientation in industrially processed grain-oriented silicon steels along the various production stages, i.e. hot rolling, cold rolling, primary annealing, and secondary annealing.

Evolution of the Goss texture during processing

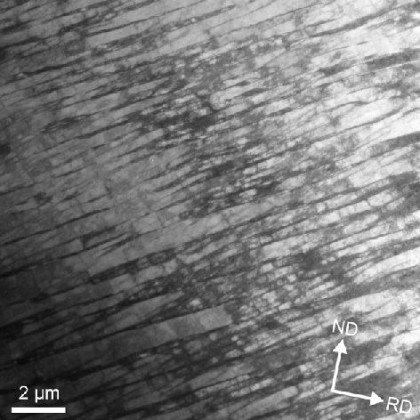

The strong Goss texture of grain-oriented silicon steel is the result of a complex processing scheme, i. e. of a long microstructural and textural inheritance chain. The origin of the evolution of the final Goss orientation is in the hot rolling stage, where the Goss orientation develops close to the sheet surface due to shear deformation. The particular importance of this Goss-containing subsurface layer has been demonstrated by experiments where this layer was removed, resulting in incomplete secondary recrystallisation. In the cold rolled material, the fraction of the Goss orientation is about 1% (considering a misorientation up to 15o) as measured using electron backscatter diffraction (EBSD) i. e. the Goss component is to weak to be detected by x-ray diffraction as used in earlier studies. In the subsequent primary annealing step, the material recrystallises and the Goss component slightly increases. In the final secondary high-temperature annealing process, normal grain growth is inhibited by particles. But some of the Goss grains that are present in the recrystallised material grow abnormally giving rise to a sharp Goss texture with an average misorientation from the exact Goss orientation of about 3°-7°.

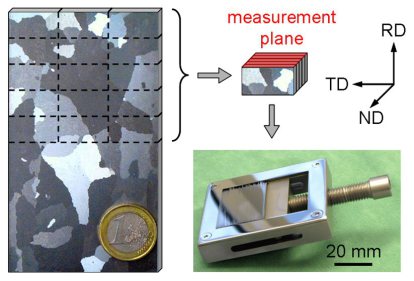

Why is the sharpness Goss texture in FeSi soft magnetic steels important and how is it measured ?

The analysis of the final Goss texture sharpness in grain-oriented electrical steels obtained after secondary recrystallization is a challenging task due to the immensely large grain size –

ranging from millimetres to centimetres – and the narrow orientation spread, i.e. the extreme sharpness of the orientation peaks. Although it has been widely claimed in the literature that the

orientation deviations from the ideal Goss orientation lie in the range of about seven degrees for conventional grain-oriented steel and about three degrees for high permeability grades, not many

accurate investigation with an appropriate statistical relevance have been published so far.

In the current investigation, a stacked sample setup in combination with large-area EBSD based orientation microscopy (EBSD: electron backscatter diffraction) was used for orientation determination

with high statistical significance. Since standard techniques of texture analysis fail in case of sharp orientation distributions, a novel method for the evaluation of the Goss orientation spread is

proposed based on discrete misorientation distributions normalized by volume in orientation space. With this, a profound study of the Goss texture sharpness is presented taking into account the major

challenges of materials with both, large grain sizes and sharp textures.

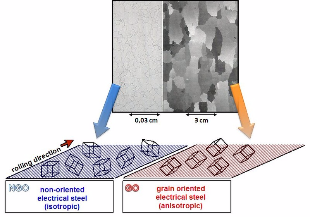

Types of electrical steels: grain- oriented electrical steel and non-oriented electrical steel

Electrical steel sheets are soft magnetic materials, for which high permeability and low magnetic core loss are the most important requirements to be met.

Therefore, electrical steel sheets are very widely used for multiple applications such as transformers, magnetic shield, and magnetic cores of electrical motors and generators. Electrical steels are

typically classified into two groups in terms of their specific magnetic anisotropy.

One group are the grain-oriented electrical steel sheet that has a very strong crystallographic Goss texture and is highly anisotropic with one or two magnetic easy axes lying in the sheet plane

since the easy axes in Fe–Si lie along the <100> directions. The other group are the non-oriented steels that. They have more raendom texture.

Grain-oriented FeSi steels are often referred to as doubly oriented electrical steels as they have has two perpendicular low-loss magnetic axes in the sheet plane.

How do Goss grain precursors form during cold rolling?

Reprints on Fe-Si soft magnetic electrical steels

This paper outlines the development of the microstructure and microtexture of grain-oriented silicon steel during the industrial production process. In particular the evolution of the Goss orientation

J Magnet Magn Mater 304 (2006) 183 Overv[...]

PDF-Dokument [288.5 KB]

The measurement of the final Goss texture sharpness in grain-oriented electrical steels is a challenging task due to the immense grain size ranging from millimeters to centimeters. Although, it is wid

J Magnetism Magnetic Materials 320 (2008[...]

PDF-Dokument [512.9 KB]

Acta Materialia 51 (2003) 1755-1765

Effects of topology on abnormal grain growth in silicon steel

N. Chen, S. Zaefferer, L. Lahn, K.Günther, D. Raabe

Acta Materialia 51 (2003) 1755 FeSi stee[...]

PDF-Dokument [283.0 KB]

This work addresses the role of grain topology on abnormal grain growth in silicon steel. The question was investigated whether the abnormal grain growth of Goss grains during secondary

recrystallization can be interpreted in terms

of an initial size advantage that these grains inherit from rolling and primary recrystallization. For this purpose the correlation between crystallographic orientation, size and number of next

neighbors of large grains in the subsurface

layer of a primary recrystallized silicon steel sheet was investigated. It was found that most of the large grains have an orientation on the h-fiber (001 axis parallel to the rolling direction)

but are not particularly close to the Goss orientation. Also, no tendency of grains to be larger the closer they are to the Goss orientation was visible. Rather it was found that the

scatter of the angular deviation to the Goss orientation is similar over a large range of grain sizes and this was found to be true too if the number of next neighbors of a grain rather than its

grain size was checked. One single grain, however, was found that was close to the Goss orientation and had a high number of next neighbors and might therefore act as a nucleus for

secondary recrystallization. Nevertheless, grains with a similarly high number of neighbors and a large deviation to the Goss orientation were found, too. Thus, a topological reason for the

Goss texture evolution could not yet be proved. However, it might be that the extreme rareness of Goss nuclei (1 out of 106 grains) has prevented, up to now, from observing a true

nucleus.

Acta Materialia 55 (2007) 2519-2530

Retention of the Goss orientation between microbands during cold rolling of an Fe3%Si single crystal

Dorothee Dorner, Stefan Zaefferer, Dierk Raabe

Acta Mater 55 (2007) 2519 Goss FeSi stee[...]

PDF-Dokument [1'014.9 KB]

An FeSi single crystal with an initial {110}<001> orientation, also referred to as Goss orientation, was cold rolled up to a thickness reduction of 89%. Most of the crystal volume

rotated into the two symmetrical {111}<112> orientations. However, a weak Goss component remained in the highly strained material, even though the Goss orientation is mechanically unstable

under plane strain loading. Two types of Goss-oriented regions were discernable in the material subjected to 89% reduction. It appeared that these two types of Goss

regions have different origins. Goss grains that were found aligned in shear bands form during straining. A second type of Goss region was found between microbands where the initial Goss

orientation was retained.

The measurement of the final Goss texture sharpness in grain-oriented electrical steels is a challenging task due to the immense grain size ranging from millimeters to centimeters. Although, it is widely claimed in the literature that the orientation deviations from the ideal Goss orientation lie in the range of about 7° for conventional grain-oriented steel and in the range of about 3° for high permeability grades, no precise investigation with an appropriate statistical relevance is known to the authors. In this work, X-ray diffraction and large-area EBSD-based orientation microscopy (EBSD: electron backscatter diffraction) were used for texture analysis and orientation determination in order to estimate the Goss orientation spread of different grades of grain-oriented steel. Two production routes for grain-oriented steel sheets are compared, the conventional route and a low heating route with lower inhibitor strength. The results of the texture measurement demonstrate that both routes deliver comparable values of orientation deviations. Furthermore, it can be shown that small differences of the magnetic properties can be correlated with the texture sharpness of the material.

Materials Science Forum Vols 495-497 (2005) pp 1061-1066

Survival of Goss grains during cold rolling of a silicon steel single crystal

- - -

A silicon steel single crystal with initial Goss orientation, i.e. the {110}<001>

orientation, was cold rolled up to 89 % thickness reduction. Most of the crystal volume rotates into the two symmetrical equivalent {111}<112> orientations. However, a weak Goss component is still present after high strain, although the Goss orientation is mechanically instable under plane strain loading. Two types of Goss-oriented crystal volumes are found in the highly deformed material. We suggest that their origin is different. The Goss-oriented regions that are observed within shear bands form during the cold rolling process. In contrast, those Goss-oriented crystal

Materials Science Forum Vols 495-497 (20[...]

PDF-Dokument [1.1 MB]

Magnetic Anisotropy of Iron

Magnetic properties of bodies can differ when tested along different directions. This effect is caused by the anisotropic character of the magnetic interaction between atomic carriers of magnetic moment in materials. Magnetic anisotropy is not always observable at a macroscopic scale in metals since in many polycrystalline alloys the elementary magnetic anisotropy that is inherent to most individual crystals mutually compensates within a randomly oriented polycrystalline aggregate (random texture). On the other hand, in single crystals the magnetic anisotropy is an observable effect, such as the difference in the value of magnetic susceptibility of paramagnetic crystals along different directions. Magnetic anisotropy is particularly large in ferromagnetic single crystals, where it is becomes detectable in terms of the presence of directions of easy magnetization, along which the vectors of spontaneous magnetization Jj of ferromagnetic domains are aligned. The energy of magnetization of an external magnetic field that is necessary to rotate the vector Js from its position along the direction of easiest magnetization to a new position along the external field is a measure of magnetic anisotropy for a given direction in a crystal. At constant temperature the energy determines the free energy of magnetic anisotropy Fan for a given direction. The dependence of Fan on the orientation of Js in a crystal is determined on the basis of symmetry considerations. For example, for cubic crystals such as Fe-Si single crystals

Fan, cubc = K1(α12α22 + α22α23 + α32α12)

where a1, a2, and a3 are the direction cosines of Js with respect to the axes of the crystal [100], and K1 is the first constant of natural crystallographic magnetic anisotropy. Its value and sign are determined by the atomic structure of the substance and also depend on the temperature and pressure. For example, at room temperature K1 is of the order of 105 ergs/ cm3, or 104 joules per cu m (J/m3), in iron and of the order of —104 ergs/cm3 (—103 J/m3) in nickel. As the temperature in-creases these quantities decrease, tending toward zero at the Curie point. In antiferromagnets, which contain at least two magnetic sublattices (J1 and J2, there are at least two constants of magnetic anisotropy. For a uniaxial antiferromagnetic crystal, Fan may be written in the form (a/2) (J1z2 + J2z) + bJ1zJ2Z (where z is the direction of the axis of magnetic anisotropy). The values of the constants a and b are of the same order as in ferromagnets. Considerable anisotropy of the magnetic susceptibility K is observed in antiferromagnets; along the direction of easy magnetization K tends toward zero with a drop in temperature, but in the direction perpendicular to the axis (below the Neel temperature) K is independent of temperature.