High strength composite wires

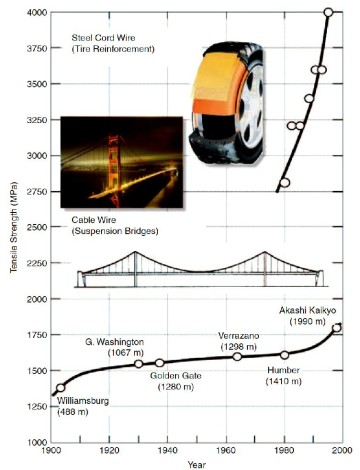

On this page I review some microstructures and properties of metal matrix composites produced by very severe plastic deformation of initially multiphase synthesized metallic alloys. Typical processings are heavy wire drawing, ball milling, roll bonding, equal-channel angular extrusion, and high-pressure torsion of multiphase metallic materials. Similar phenomena occur between solids in frictional contact such as in tribology, friction stir welding, and explosive joining. The resulting heavily strained compounds are characterized by very high interface and dislocation density, chemical mixing, and atomic-scale structural transitions at heterointerfaces. Many of these effects are also highly size-dependent. Upon straining, the phases form into nanoscaled filaments. This leads to enormous strengthening combined with good ductility, as in damascene steels or pearlitic wires, which are among the strongest nanostructured bulk materials available today (tensile strength above 6 GPa). Similar materials are Cu-Nb and Cu-Ag composites, which also have good electrical conductivity that qualifies them for use in high-field magnets. Beyond the engineering opportunities, there are also exciting fundamental questions. They relate to the nature of the complex dislocation, amorphization, and mechanical alloying mechanisms upon straining and their relationship to the enormous strength. Studying these mechanisms is enabled by mature atomic-scale characterization and simulation methods. A better understanding of the extreme strength in these materials also provides insight into modern alloy design based on complex solid solution phenomena.

Metallic composites processed via extreme deformation: Toward the limits of strength in bulk materials

Metals_at_extremes-MRS_Bulletin-Dec2010-[...]

PDF-Dokument [2.2 MB]