ICEM: Integrated Computational Materials Engineering

D. Helm, A. Butz, D. Raabe, P. Gumbsch, Microstructure-Based Description of the Deformation of Metals: Theory and Application. JOM 63 (2011) 26-33.

2011-overview-microstructure-models-JOM.[...]

PDF-Dokument [1.5 MB]

What is ICME: Integrated Computational Materials Engineering?

Integrated Computational Materials Engineering (ICME) refer to a holistic methodology for designing materials, processes and advanced products, by systematiclly linking experiments at different length scales with scale-matching materials models at multiple length scales. Key words are "Integrated", involving integrating models at multiple length scales, and "Engineering", adressing and considering the boundary conditions set by industrial manufacturing. The focus of ICME is placed on the materials, i.e. on understanding how processes produce material microstructures, how those microstructures give rise to specific material properties, and how to select or design materials for a given application. The key links are process-structures-properties-performance.

Why using Integrated Computational Materials Engineering?

The underlying rationale behind the Integrated Computational Materials Engineering approach is to render materials, microstructures, structure-property relationships and processing accessible

to a holistic computational materials science description and prediction with the aim of reaching quantitative predictive quality.

The overarching challenge behind this approach lies in obtaining a complete and closed simulation description of the entire manufacturing chain and the final product's performance when in

service.

Materials for which a complete and quantitative computational description is not reached will in future most likely be excluded from use in commercial applications at least in safety relevant parts.

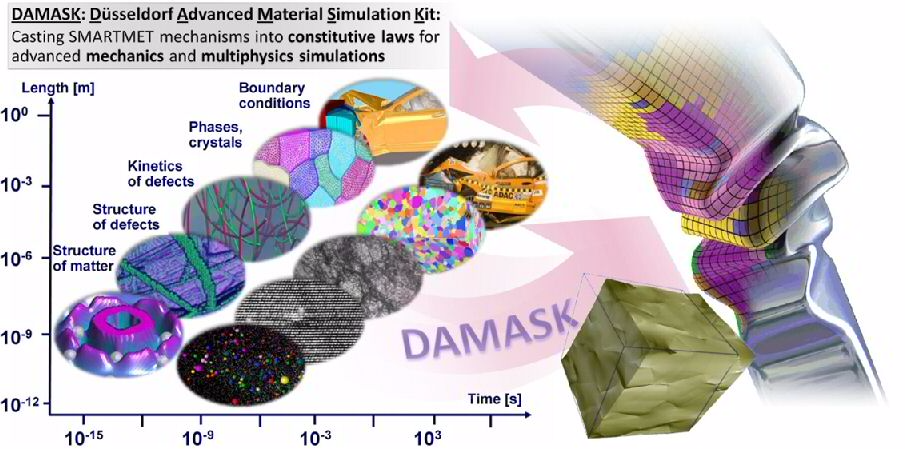

Why and how using DAMASK for Integrated Computational Materials Engineering?

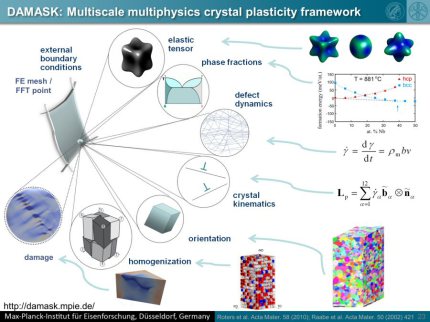

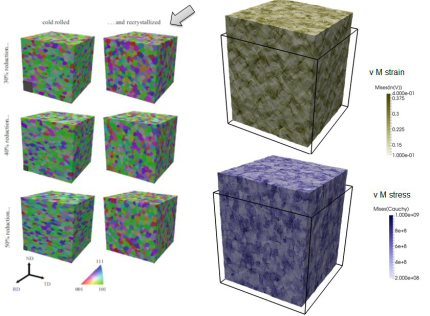

The freeware DAMASK simulation package is a flexible and hierarchically structured model of material point behavior for the solution of elastoplastic boundary value problems along with plasticity, twinning, martensite formation, softening, damage, diffusive phase transformation, transport and thermal physics. Its main purpose is the simulation of crystal plasticity and the associated phenomena together with multiphasics-type transformation and transport phenomena within a finite-strain continuum mechanical framework.

Procedia IUTAM 3 ( 2012 ) 3-10

DAMASK: the Düsseldorf Advanced MAterial Simulation Kit for studying crystal plasticity using an FE based or a spectral numerical solver

Procedia IUTAM 3 ( 2012 ) 3 MPIE DAMASK [...]

PDF-Dokument [1.4 MB]

Crystal Plasticity Finite Element Modeli[...]

PDF-Dokument [3.6 MB]

Integrated Computational Materials Engineering for developing advanced twinning induced plasticity steels (TWIP)

The twinning-induced plasticity (TWIP) effect enables designing austenitic Fe-Mn-C- based steels with >70% elongation at an ultimate tensile strength >1 GPa. These steels are characterized by high strain strain-hardening due to the formation of twins and complex dislocation substructures which that dynamically reduce the dislocation mean free path. Both mechanisms are governed by the stacking-fault energy, which depends on the chemcial composition. This connection between composition and substructure renders these steels ideal model materials for theory-based alloy design: Ab initio-guided elemental composition adjustment is used to tune the stacking-fault energy, and thus, the strain-hardening behavior for promoting the onset of twinning at intermediate deformation levels where the strain-hardening capacity provided by the dislocation substructure gets exhausted. In this ICME project we conduct thermodynamic simulations and use the results in constitutive models. Also we couple these studies with electron microscopy and combinatorial methods that enable validation of the strain-hardening mechanisms.

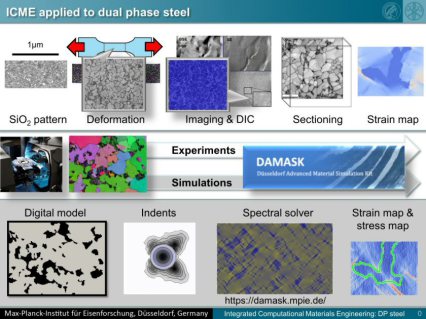

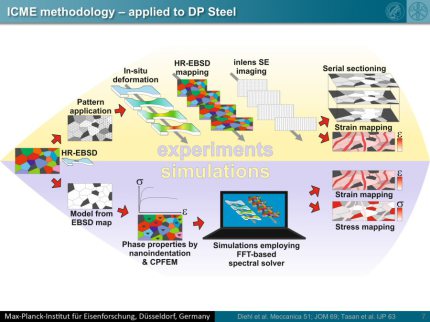

International Journal of Plasticity 63 (2014) 198-210

Strain localization and damage in dual phase steels investigated by coupled in-situ deformation experiments and crystal plasticity simulations

Intern Journ Plasticity 63 (2014) 198 In[...]

PDF-Dokument [964.9 KB]

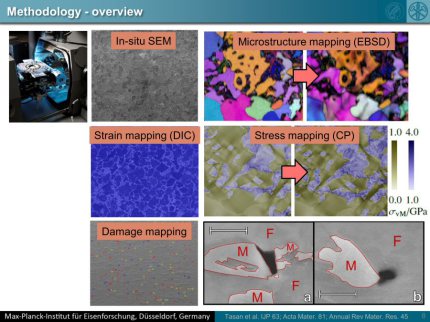

Acta Materialia 81 (2014) 386-400

Integrated experimental–simulation analysis of stress and strain partitioning in multiphase alloys

Tasan et al Acta Materialia vol 91 2014 [...]

PDF-Dokument [3.4 MB]

Acta Materialia 58 (2010) 1152-1211

Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications

Roters Acta Materialia 58 (2010) 1152 cr[...]

PDF-Dokument [3.6 MB]