Magnesium Alloys

Magnesium alloys, as one of the lightest commercially used structural materials, are traditionally used in aircraft and spacecraft applications. Magnesium alloys also have high specific strength and elastic stiffness, good machinability and excellent damping capacity.

Current trends to reduce energy consumption lead to efforts to minimize both total weight and the weight of moving part of vehicles. Therefore, lately, to an

increasing rate, wrought magnesium alloys in automotive applications are considered, which can significantly decrease the weight of vehicles. Magnesium alloys are also used for manufacture of

housings of many portable electronic devices, such as, cellular phones or notebooks, not only for the material lightness but also for the easiness of recycling and good electromagnetic shielding

capabilities. These replace castings with wrought products, including complex shape precision forgings.

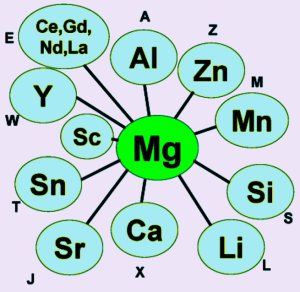

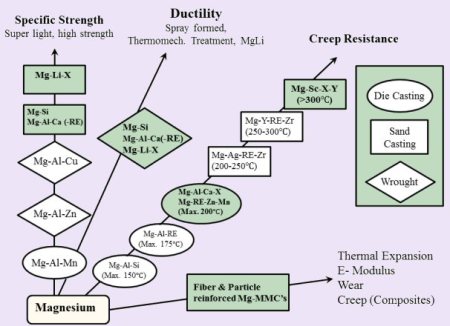

The Mg alloy systems are divided into Al-containing and Al-free compositions.

The most frequently used alloys are those based on the Mg-Al system, such as Mg-Al-Zn (referred to as AZ) and Mg-Al-Mn (AM series). Their weak creep resistance

is related to the occurrence of a low-melting Mg17Al12 phase, rendering such materials unsuited for applications above 120°C. The Mg-Al-RE (AE series), Mg-Al-Ca-Sr (AXJ series), and Mg-Al-Sr (AJ

series) have better creep resistance, since their microstructure is characterized by the presence of second phases from system Al-RE, Al-Sr or Al-Ca at the grain boundaries which are stable compounds

with a relatively high melting point. The maximum operating temperature of these alloys do not exceed 180°C.

The basic systems for Al-free magnesium alloys are Zr-containing alloys such as Mg-Zn-Zr (ZK series), Mg-Nd-Y-Zr (WE series), Mg-Ag-Nd-Zr (QE series),

Mg-Gd-Nd-Zr (Elektron 21), Mg-Zn-RE-Zr (ZE series), Mg-Th-Zr. These alloys are predicted mainly to gravity casting and their maximum operating temperature approaches 300°C. Among these alloys, ZRE1

magnesium alloy exhibits good creep properties up to 200°C. This alloy containing zinc, rare earth metals and zirconium. Zinc is usually used in combination with aluminum, zirconium, rare earths, or

thorium to produce precipitation-hardenable magnesium alloys having good strength. Zinc also helps overcome the harmful corrosive effect of iron

and nickel impurities that might be present in the magnesium alloy. Rare earth metals are added either as 'mischmetal compound' to reduce synthesis costs.

Additions of the rare earth elements drastically improve ductility and increase the strength at elevated temperatures. They also reduce weld cracking and porosity because they narrow the freezing

range of the alloys. Zirconium has a string grain-refining effect on magnesium alloys.

The Elektron ZRE1 alloy exhibits excellent casting characteristics with components being both pressure tight and weldable.

The main Mg alloy classes are

• Mg-Al casting alloys

• Mg-Al-Zn casting alloys

• Mg-Zn and Mg-Zn-Cu casting alloys

• Mg-Zn-Zr and Mg-RE-Zn-Zr casting alloy

• High temperature Mg casting alloys

• Wrought Mg alloys

Alloy Symbol Key for Magnesium Alloys:

Letters plus numbers indicate the alloying elements added to Mg in weight % and rounded to the nearest whole number. For example AZ31 indicates the alloy Mg-3Al-1Zn.

|

Code Letter |

Alloying Element |

|

A |

Aluminum |

|

B |

Bismuth |

|

C |

Copper |

|

D |

Cadmium |

|

E |

Rare Earth |

|

F |

Iron |

|

G |

Magnesium |

|

H |

Thorium |

|

K |

Zirconium |

|

L |

Lithium |

|

M |

Manganese |

|

N |

Nickel |

|

P |

Lead |

|

Q |

Silver |

|

R |

Chromium |

|

S |

Silicon |

|

T |

Tin |

|

W |

Yttrium |

|

Y |

Antimony |

|

Z |

Zinc |

Magnesium Alloying Element Effects

|

Alloying Element |

Melting and Casting Behavior |

Mechanical and technological properties |

Corrosion behavior I/M produced

|

|

Ag |

|

Improves elevated temp tensile and creep props. In the presence of rare earths. |

Detrimental influence on corrosion behavior |

|

Al |

Improves castability, tendency to microporosity |

Solid solution hardener, precipitation hardening at low temps. |

Minor influence |

|

Be |

Significantly reduces oxidation of melt surface at very low concentrations, leads to coarse grains.

|

|

|

|

Ca |

Effective grain refining effect, slight suppression of oxidation of the molten metal.

|

Improves creep properties. |

Detrimental influence on corrosion behavior |

|

Cu |

System with easily forming metallic glasses, improves castability.

|

|

Detrimental influence on corrosion behavior, limitation necessary. |

|

Fe |

Magnesium hardly reacts with mild steel crucibles |

|

Detrimental influence on corrosion behavior, limitation necessary.

|

|

Li |

Increases evaporation and burning behavior, melting only in protected and sealed furnaces.

|

Solid solution hardener at ambient temperatures, reduces density, enhances ductility. |

Decreases corrosion properties strongly, coating to protect from humidity is necessary. |

|

Mn |

Control of Fe content by precipitating Fe-Mn compound, refinement of precipitates.

|

Increase creep resistance. |

Improves corrosion behavior due to iron control effect. |

|

Ni |

System with easily forming metallic glasses.

|

|

Detrimental influence on corrosion behavior, limitation necessary.

|

|

Rare Earth |

Improve castability, reduce microporosity. |

Solid solution and precipitation hardening at ambient and elevated temps; improve elevated temp tensile and creep properties. |

|

Si |

Decreases castability, forms stable silicide compounds with many other alloying elements, compatible with Al, Zn, and Ag, weak grain refiner.

|

Improves creep properties. |

|

Th |

Suppresses microporosity. |

Improves elevated temp tensile and creep properties, improves ductility, most efficient alloying element. |

|

Y |

Grain refining element |

Improves elevated temp tensile and creep properties.

|

|

Zn |

Increases fluidity of the melt, weak grain refiner, tendency to microscopy. |

Precipitation hardening, improves strength at ambient temps, tendency to brittleness and hot shortness unless Zr refined.

|

|

Zr |

Most effective grain refiner, incompatible with Si, Al, and Mn, removes Fe, Al, and Si from the melt. |

Improves ambient temperature tensile properties slightly. |

Commercially relevant Magnesium Alloys and their main property

|

Alloy |

Characteristics |

|

AZ63 |

Good room temperature strength and ductility |

|

AZ81 |

Tough, leaktight castings with 0.0015 Be, used for pressure die-casting |

|

AZ91 |

General-purpose alloy used for sand and diecastings |

|

AM50 |

High-pressure diecastings |

|

AM20 |

Good ductility and impact strength |

|

AS41 |

Good creep properties to 150ºC |

|

AS21 |

Good creep properties to 150ºC |

|

AE42 |

Good creep properties to 150ºC |

|

ZK51 |

Sand castings, good room temperature strength and ductility |

|

ZK61 |

As for ZK51 |

|

ZE41 |

Sand castings, good room temperature strength, improved castability |

|

ZC63 |

Pressure-tight castings, good elevated temperature strength, weldable |

|

EZ33 |

Good castability, pressure-tight, weldable, creep resistant to 250ºF |

|

HK31 |

Sand castings, good castability, weldable, creep resistant to 350ºC |

|

HZ32 |

As for HK31 |

|

QE22 |

Pressure tight and weldable, high proof stress to 250ºC |

|

QH21 |

Pressure-tight, weldable, good creep resistance and proof stress to 300ºC |

|

WE54 |

High strength at room and elevated temperatures |

|

WE43 |

Good corrosion resistance, weldable |

|

M1 |

Low-to medium- strength alloy, weldable, corrosion resistant |

|

AZ31 |

Medium-strength alloy, weldable, good formability |

|

AZ61 |

High-strength alloy, weldable |

|

AZ80 |

High-strength alloy |

|

ZM21 |

Medium-strength alloy, good formability, good damping capacity |

|

ZK30 |

High-strength alloys |

|

ZK60 |

Good formability |

|

ZMC711 |

High-strength alloy |

|

HK31 |

High creep resistance to 350ºC, weldable |

|

HM21 |

High creep resistance to 350ºC, short time exposure to 425ºC, weldable |

|

WE43 |

High temperature creep resistance |

|

WE54 |

High temperature creep resistance |

|

LA141 |

Ultra-light weight |

Literature on Mg alloys

Acta Materialia 57 (2009) 69-76

Acta Materialia 57 (2009) 69–76 ab initi[...]

PDF-Dokument [499.7 KB]

Ab initio calculations are becoming increasingly useful to engineers interested in designing new alloys, because these calculations are able to accurately predict basic material properties

only knowing the atomic composition of the material. In this paper, single crystal elastic constants of 11 bcc Mg–Li alloys are calculated using density functional theory (DFT) and compared with

available experimental data. Based on DFT determined properties, engineering parameters such as the ratio of bulk modulus over shear modulus (B/G) and the

ratio of Young’s modulus over mass density (Y/q) are calculated. Analysis of B/G and Y/q shows that bcc Mg–Li alloys with 30–50 at.% Li offer the most potential as lightweight structural

material. Compared with fcc Al–Li alloys, bcc Mg–Li alloys have a lower B/G ratio, but a comparable Y/q ratio. An Ashby map containing Y/q vs B/G shows that it is not possible to increase both

Y/q and B/G by changing only the composition of a binary alloy.

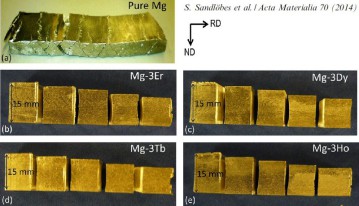

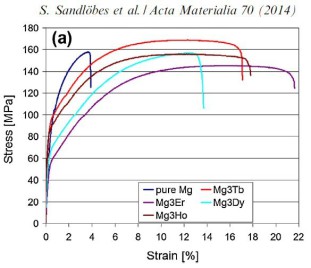

F. Wang, S. Sandlöbes, M. Diehl, L. Sharma, F. Roters, D. Raabe

Acta Materialia 80 (2014) 77-93

Collective grain-scale mechanics in Mg and Mg–rare earth alloys

Acta Materialia 2014 Sandlobes Mg rare e[...]

PDF-Dokument [1.1 MB]

Magnesium has a low mass density of 1.74 g / cm3 and is the lightest structural metal [1]. Magnesium and its alloys have received great attention for potential use in

automotive applications [2]. However, the application of wrought

magnesium alloys is restricted by its poor formability at ambient temperatures caused by its strong basal-type texture developed during processing and the lack of available deformation

mechanisms [3].

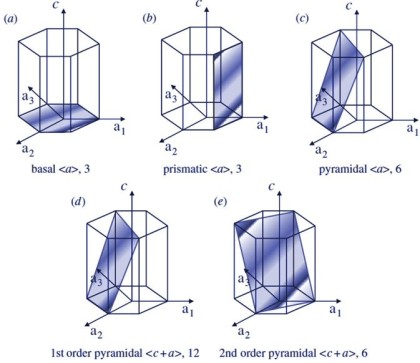

The primary deformation modes at room temperature in magnesium and magnesium alloys are basal slip and f1012g tension twinning. Both are easy to activate and have critical resolved

shear stress (CRSS) values of a few MPa according to single crystal experiments [4]. The prevalence of basal dislocation slip produces a fiber texture where the basal planes are

closely aligned with the primary material flow direction, limiting the contribution of the basal slip system to further deformation [5,6]. Besides non-basal dislocation slip, twinning

can accommodate strain along the crystal c-axis, providing additional degrees of freedom matching the requirement for five independent shear systems in the classical

Taylor–Bishop–Hill sense [7,8]. However, it was earlier observed via a joint experimental-simulation grain scale micromechanical analysis [9] that if the Taylor–Bishop–Hill criterion

is not fulfilled everywhere at the grain scale, collective deformation of grain clusters can in certain cases provide a sufficient

number of shear degrees of freedom for compatible polycrystalline deformation [10]. Due to the limitation of available deformation systems, plastic heterogeneities and

strain localization in the form of shear bands [11] occur during room temperature deformation of Mg [12–18]. The mechanisms

associated with such shear band formation in Mg alloys are not well understood [12–18]; some studies suggest 101 1 compression twinning [12,14], double-twinning [14,18], tension

twinning [13] or rotational recrystallization

[17] as possible mechanisms of shear band formation. Shear banding in Mg is a mesoscopic “grain-cluster” deformation process where the grains inside the shear band are reported to

subsequently re-orient in the macroscopic shear

direction, i.e. “soften” the sheared region with respect to further basal dislocation slip during continuing deformation [15,17,18].

Similarly, it is well known that twins appear also in grains not suitably oriented for twinning. This anomalous twinning or, more specifically, non-Schmid behaviour of twinning was

observed in rolled sheets and extruded Mg alloys, e.g. Refs. [19–23]. With the non-Schmid behaviour of twin variant selection we refer to the fact that the micromechanical i.e. the local

stress state may profoundly deviate from the macroscopic loading state. It should be noted though that the term non-Schmid behaviour sometimes also refers to the effect of hydrostatic

tensor components on plastic flow: this definition is not used here.

Apparently, the local microstructure plays an important role in twin activation and topology, besides the dependence on crystallographic orientation or grain size, on which many

studies have focused before, e.g. Refs. [23,24]. Grain boundaries are important sites for twin nucleation given that they provide defect sources and stress peaks. The interaction

between twinning and grain boundaries was investigated in polycrystalline hexagonal close packed (hcp) Mg and hcp Ti [12,25,26]. It is found that twin nucleation is not solely

controlled by Schmid’s law, i.e. a twin variant with a lower Schmid factor might nucleate

instead of the expected high Schmid factor twin variant.

The microstructure evolution of pure Mg and two Mg–rare-earth alloys (Mg–3 wt.% Dy and Mg–3 wt.% Er) was studied during in situ compression tests by electron backscatter diffraction and

electron channelling contrast imaging. Strain localization and the formation of an early stage shear band (“pre-shear band”) were observed in pure Mg during compressive deformation below 5%

engineering strain. In the experiments percolative grain clusters with prevalent basal slip as a precursor for shear band formation was observed. This

collective grain-cluster shear behaviour was analysed in more detail using crystal plasticity simulations, revealing a percolation of intense basal slip activity across grain boundaries as the

mechanism for shear band initiation. Plane trace analysis, Schmid factor calculation and deformation transfer analysis at the grain boundaries were performed for the activated twins. It appears

that many activated tension twins exhibit pronounced non-Schmid behaviour. Twinning appears to be a process of accommodating local strain rather than a response to macroscopic strain.

Scientific Reports| 7: 10458 | DOI:10.1038/s41598-017-10384-0

Ductile Magnesium Calcium Aluminium Scie[...]

PDF-Dokument [2.8 MB]

While other metallic alloys have multiple dislocation slip systems, enabling their well-known ductility, the hexagonal lattice of magnesium offers insufficient modes of deformation, rendering it intrinsically brittle. We have developed a quantum-mechanically derived treasure map which screens solid solution combinations with electronic bonding, structure and volume descriptors for similarity to the ductile magnesium-rare earth alloys. Using this insight we synthesized a surprisingly simple, compositionally lean, low-cost and industry-compatible new alloy which is over 4 times more ductile and 40% stronger than pure magnesium. The alloy contains 1 wt.% aluminum and 0.1 wt.% calcium, two inexpensive elements which are compatible with downstream recycling constraints.

C. Zambaldi, C. Zehnder and D. Raabe

Orientation dependent deformation by slip and twinning in magnesium during single crystal indentation

Acta Materialia 91 (2015) 267-288

Acta Materialia 91 (2015) 267 Magnesium [...]

PDF-Dokument [2.1 MB]

We present the orientation dependent indentation response of pure magnesium during single grain indentation. A conical indenter and maximum loads between 50 mN and 900 mN were employed.

Indent topographies were acquired by confocal microscopy. The indents were also characterized by electron backscatter orientation microscopy for their microstructures. Pronounced activation of

specific twinning systems was observed around the impressions. The resulting data were compiled into the inverse pole figure presentation of indent microstructures and topographies after

Zambaldi and Raabe, Acta Mater. (2010). Three-dimensional crystal plasticity finite element simulation of the indentation deformation supports the interpretation of the orientation dependent

slip and twinning patterns around the indents. The match between the activation of observed and simulated twinning variants is discussed with respect to the conditions for nucleation and growth

of extension twins. Furthermore, the compatibility of the twinning strains with the imposed deformation is discussed based on the expanding cavity model of indentation. The orientation

dependent

response of magnesium during indentation is compared to the literature data for indentation of alpha-titanium and beryllium. Recommendations are given on how to exploit the characteristic nature

of the observed indentation patterns to rapidly assess the relative activity of deformation mechanisms and their critical shear stresses during alloy development.

New Journal of Physics 15 (2013) 043020

New Journal of Physics 15 (2013) 043020 [...]

PDF-Dokument [1.1 MB]

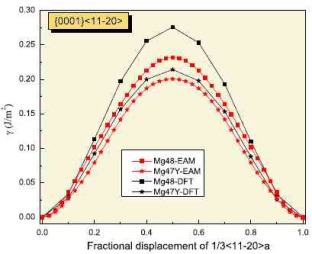

Magnesium–yttrium alloys show significantly improved room temperature ductility when compared with pure Mg. We study this interesting phenomenon theoretically at the atomic scale

employing quantum-mechanical (so-called ab initio) and atomistic modeling methods. Specifically, we have calculated generalized stacking fault energies for five slip systems in

both elemental magnesium (Mg) and Mg–Y alloys using (i) density functional theory

and (ii) a set of embedded-atom-method (EAM) potentials. These calculations

predict that the addition of yttrium results in a reduction in the unstable stacking

fault energy of basal slip systems. Specifically in the case of an I2 stacking

fault, the predicted reduction of the stacking fault energy due to Y atoms was

verified by experimental measurements.We find a similar reduction for the stable stacking fault energy of the {11¯22}<11¯23> non-basal slip system. On the other hand, other energies

along this particular gamma-surface profile increase with the addition of Y. In parallel to our quantum-mechanical calculations, we have also developed a new EAM Mg–Y potential and

thoroughly tested its performance. The comparison of quantum-mechanical and atomistic results indicates that the new potential is suitable for future large-scale atomistic simulations.

MSF.690.202.pdf

PDF-Dokument [989.3 KB]

Ductile Magnesium Alloys

Magnesium based alloys are highly attractive for structural applications owing to their low mass density, high specific strength, good castability and efficient recyclability. However, wider commercial application of sheet Mg alloys is hindered by their poor room temperature formability, which is caused by pronounced basal slip and a strong basal-type crystallographic texture. It was observed however that alloying Y and / or certain rare earth elements such as Ce can have very positive effects on the mechanical response of structural Mg alloys. Among these effects are texture weakening and room temperature ductility increase.

Many phenomenological studies were performed on the influence of rare earth addition on Mg texture formation. While pure Mg and conventional Mg alloy sheets typically show a strong basal texture, Mg- rare earth alloys have a weaker basal-type texture which is characterized by the broadening of the basal poles towards the sheet rolling direction, leading to the so-called r-type texture (RD). Extrusion of Mg- rare earth alloys leads to the formation of a weak <11-21> fibre texture, which is also referred to as rare-earth texture component. The texture weakening effect was attributed to grain boundary pinning at Mg- rare earth precipitates and local lattice rotations around the precipitates. Additionally, it was shown that recrystallization nuclei at local deformation bands in Mg-Y and Mg- rare earth alloys have more random orientations than those formed more remote from local deformation bands. Talal et al. studied the role of RE addition on the texture and deformation behaviour of Mg alloys and concluded from their experimental results that more deformation mechanisms than just basal <a> slip and tensile twinning were most likely active. Other studies reported more intense activity of compression / secondary twinning and non-basal dislocation slip in rare earth -containing alloys, when compared to conventional Mg alloys and the formation of homogeneously distributed deformation or shear bands.

None of the early studies addressed the underlying rare earth -induced plasticity mechanisms which are not fully understood. More specifically, the origin of the beneficial Y and rare earth solid solution effects on the ductilization of Mg remain unresolved.

Atomistic studies using density functional theory (DFT) and molecular dynamics (MD) calculations aiming at clarifying the influence of solutes on the mechanical response of Mg alloys were performed for basal dislocations and the basal SF I2. The DFT results were used as input parameters to the Fleischer solid solution strengthening model. These results suggest that solutes increasing the I2 SFE lead to improved cross-slip probability of basal dislocations onto prismatic planes and, thus, improve ductility.

The relation between ductility and stacking fault energies in Mg and Mg–Y alloys

Acta_Mater_60_3011-3021-Mg-SFE-DFT-and-T[...]

PDF-Dokument [1.0 MB]

The I1 intrinsic stacking fault energy (I1 SFE) serves as an alloy design parameter for ductilizing Mg alloys. In view of this effect we have conducted quantum–mechanical calculations for Mg15X soli

Ductility of Mg rare earth alloys ab ini[...]

PDF-Dokument [4.6 MB]

Room temperature deformation of LPSO structures by non-basal slip

Magnesium alloys are attractive structural materials due to their low density, high specific strength and good recyclability. However, due to the hexagonal crystal structure of Mg and

the related crystallographic anisotropy, only a limited set of slip systems is available resulting in poor room temperature ductility. Recently Mg-Y-Zn and Mg-Zn-RE alloys containing

long period stacking ordered (LPSO)

structures have been reported to possess both high strength and good toughness. This excellent mechanical performance has been reported to be related to the presence of LPSO structures, however,

the underlying mechanisms for the concomitant increase of strength and toughness are not fully understood. LPSO structures are chemically and structurally ordered where RE/Y and Zn

atoms occupy Mg positions on neighboring {0001} planes. They share the {0001} basal plane of Mg but are stacking ordered along the c-axis, resulting in stacking periods such as 10H,

14H, 18R and 24R. For pure Mg and most magnesium alloys, {0001} 1120 basal < a > dislocation slip and {1012} 1011 twinning are the two predominant deformation mechanisms at room

temperature. However, it has been shown for LPSO structures that twinning is strongly inhibited due to the long stacking periodicity and ordering of RE and Zn atoms. Instead, the

formation of kink bands has been reported during

deformation of LPSO grains, which - together with basal dislocation slip - effectively carries the strain in LPSO structures at room temperature. Previous studies also suggest only

limited activity of non-basal slip which has been observed only in regions with high local stress concentrations such as adjacent to kink bands during room temperature deformation of

LPSO grains.

Generally, the activation of deformation systems strongly depends on the crystallographic texture and the loading direction. Therefore, this study aims at investigating the active

deformation mechanisms in LPSO structures at room temperature under conditions where both, basal slip and kink band formation, are restricted. To this end we investigated the room

temperature tensile deformation behavior of an extruded Mg97Y2Zn1 (at%) alloy which was deformed by tensile loading parallel to the basal planes, hence, restricting the

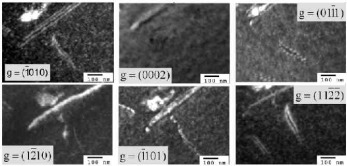

activation of basal slip and kink band formation. By combined slip trace analysis, electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) we observed a

surprising prevalence of non-basal < a > slip in the LPSO structures.

Materials Science & Engineering A 682 (2017) 354

Rom temperature ductility Mg LPSO MSE A [...]

PDF-Dokument [1'005.4 KB]

Ductile room temperature deformation of Mg–Y–Zn alloys with long-period-stacking-ordered (LPSO) structures

Transmission electron microscopy study on room temperature deformation of a Mg97Y2Zn1 (at.%) alloy with long-period-stacking-order (LPSO) phase. The alloy consists of a-Mg matrix with platelet-shaped LPSO precipitates 3–5 nm thick and interdendritic LPSO (18R structures) phase grains. The interdendritic LPSO phase deforms either by kink-banding in conjunction with basal <a> slip or by basal <a> slip and the formation of dislocation walls. The Mg matrix deforms by basal <a> slip and pyramidal <c + a> slip. No twinning was observed in the a-Mg matrix during room temperature deformation. The elastic modulus mismatch between a-Mg matrix and LPSO plates is suggested to be the main source for activating non-basal dislocations.

Transmission electron microscopy study on room temperature deformation of a Mg97Y2Zn1 (at.%) alloy with long-period-stacking-order (LPSO) phase. The alloy consists of a-Mg matrix with platelet-shaped LPSO precipitates 3–5 nm thick and interdendritic LPSO (18R structures) phase grains. The interdendritic LPSO phase deforms either by kink-banding in conjunction with basal <a> slip or by basal <a> slip and the formation of dislocation walls. The Mg matrix deforms by basal <a> slip and pyramidal <c + a> slip. No twinning was observed in the a-Mg matrix during room temperature deformation. The elastic modulus mismatch between a-Mg matrix and LPSO plates is suggested to be the main source for activating non-basal dislocations. The combination of the soft a-Mg matrix strengthened by LPSO precip

Acta Mater 2014 Magnesium LPSO room temp[...]

PDF-Dokument [1.1 MB]