Medium Mn Steels

What are medium Mn steels ?

Medium Mn steels establish an imnportant class of novel alloys in the 3rd generation of advanced high

strength steels (AHSS).

These alloys have a manganese content between 3-12 wt.% and often multiple phase-like microstructure ingredients and phases.

They show a good combinations of high to ultra-high strength at quite high total elongation. Ultra-fine grained microstructures can be achieved via intercritical annealing, resulting in a

complex multi-phase microstructure consisting of several phases such as different types of austenite (retained,

partition

stabilized, reverted), martensite, ferrite and sometimes also delta ferrite.

Especially the different types of austenite in medium Mn steels promote enhanced ductility due to the higher strain hardenability enabled by dislocation accumulation, TRIP effect or even the

TWIP effects.

Adjusting alloy composition and adequate selection of the intercritical annealing temperature and pre-deformation results in the formation of different types of beneficial microstructures at

room temperature.

Competition between formation of carbides and reversed austenite during tempering of medium-manganese steels

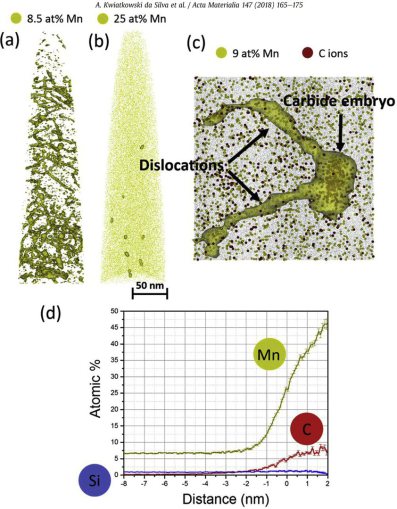

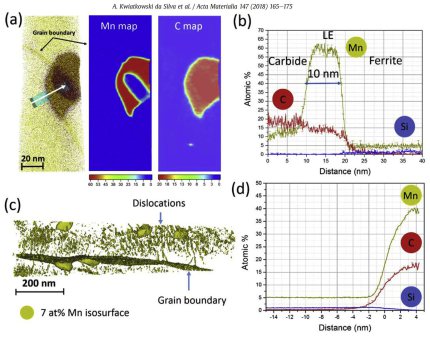

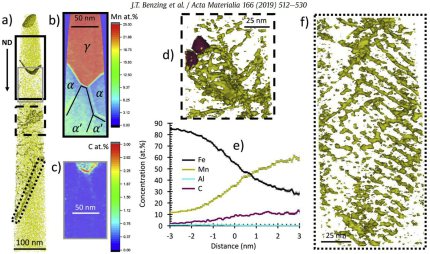

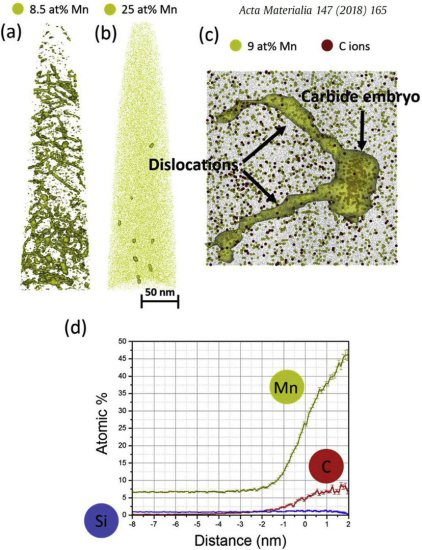

We investigated the thermodynamics and kinetics of carbide precipitation in a cold-rolled Fe-7Mn-0.1C-0.5Si medium manganese steel during low temperature tempering. The material was annealed up

to 24 h at 450 C in order to follow the kinetics of precipitation. Using thermodynamics and kinetics simulations, we predicted the growth of M23C6 carbides according to the local-equilibrium

negligible partition (LENP) mode where carbide growth is controlled by the diffusion of carbon, while maintaining local chemical equilibrium at the interface. Atom-probe tomography (APT)

measurements performed on samples annealed for 1, 6 and 24 h at 450 C confirmed that LENP is indeed the mode of carbide growth and that Mn segregation is necessary for the nucleation.

Additionally, we observed the heterogeneous nucleation of transition carbides with a carbon content between 6 and 8 at% at segregated dislocations and grain boundaries. We describe these

carbides as a complex face-centered cubic transition carbide

type (CFCC-TmC phase) obtained by the supersaturation of the FCC structure by carbon that will act as precursor to the more stable g-M23C6 carbide that forms at the dislocations and grain

boundaries. The results suggest that the addition of carbon does not directly favor the formation of austenite, since Mn is

consumed by the formation of the carbides and the nucleation of austenite is thus retarded to later stages of tempering as every FCC nucleus in the initial stages of tempering is readily

converted into a carbide nucleus. We propose the following sequence of transformation: (i) carbon and Mn co-segregation to

dislocations and grain boundaries; (ii) formation of FCC transition carbides; (iii) growth controlled according to the LENP mode and (iv) austenite nucleation and growth.

The mechanism of precipitation of M23C6 carbides during the different stages of tempering of a medium Mn martensite was described by thermodynamics and kinetics simulations and followed experimentally by APT. Co-segregation of Mn and C is

required as a precondition for the formation of the M23C6 carbide, which is preceded by the formation of metastable FCC carbides. Once the first nucleus is formed, M23C6 growth will proceed by a LENP reaction. The homogenization of the Mn content inside the carbide will occur after extended periods of tempering. The

nucleation of austenite is belated due to the formation of the carbides, indicating that C poisons the nucleation of austenite at lower temperatures.

Competition_between_formation_of_carbide[...]

PDF-Dokument [4.6 MB]

What is the advantage of medium Mn steels compared to other high strength streels ?

Medium Mn steels with 3.12 wt% Mn content emerge as strong candidate alloys for the 3rd generation of advanced high strength steels, due to their excellent strength-ductility combination

(product of tensile strength and total elongation up to ~70 GPa%), simple heat treatment process (e.g. intercritical annealing (IA)), and low-cost alloy ingredients. The composite-like

microstructure (normally

ferrite and metastable austenite) combined with submicron grain scale differentiates such materials from other types of alloys.

What are Advanced High-Strength Steels?

Advanced high-strength steels (AHSS) constitute a class of high-strength, formable metallic alloys that are designed mainly as sheet products for the transportation sector. AHSS have often very complex and hierarchical microstructures consisting of ferrite, austenite, bainite, or martensite matrix or of duplex or even multiphase mixtures of these constituents, sometimes enriched with precipitates. This complexity makes it challenging to establish reliable and mechanism-based microstructure–property relationships. A number of excellent studies already exist about the different types of AHSS (such as dual-phase steels, complex phase steels, transformation-induced plasticity steels, twinning-induced plasticity steels, bainitic steels, quenching and partitioning steels, press hardening steels, etc.) and several overviews appeared in which their engineering features related to mechanical properties and forming were discussed.

This is a viewpoint paper on recent progress in the understanding of the microstructure–property relations of advanced high-strength steels (AHSS). These alloys constitute a class of high-strength, formable steels that are designed mainly as sheet products for the transportation sector. AHSS have often very complex and hierarchical microstructures consisting of ferrite, austenite, bainite, or martensite matrix or of duplex or even multiphase mixtures of these constituents, sometimes enriched with precipitates. This complexity makes it challenging to establish reliable and mechanism-based microstructure–property relationships.

Raabe_et_al-2020-Metallurgical_and_Mater[...]

PDF-Dokument [28.2 MB]

Overview of Advanced High-Strength Steels

We wrote an article about the recent progress in the understanding of microstructures and alloy design of Advanced High Strength Steels placing particular attention on the deformation and strain hardening mechanisms of Mn-containing steels that utilize complex dislocation substructures, nanoscale precipitation patterns, deformation-driven transformation, and twinning effects. Recent developments on microalloyed nanoprecipitation hardened and press hardening steels are also reviewed. Besides providing a critical discussion of their microstructures and properties, features such as their resistance to hydrogen embrittlement and damage formation are also evaluated. We also present latest progress in advanced characterization and modeling techniques applied to AHSS. Finally, emerging topics such as machine learning, through-process simulation, and additive manufacturing of AHSS are discussed. The aim of this viewpoint is to identify similarities in the deformation and damage mechanisms among these various types of advanced steels and to use these observations for their further development and maturation.

What is the role of discontinuous plastic yielding in medium Mn steels ?

A drawback of medium Mn steels is that they often show a discontinuous plastic yielding phenomenon. This is characterized by a yield point drop followed by a stress plateau (also referred to as yield point elongation, YPE) in the tensile stress-strain curves and the formation of Lüders bands.

Such localized deformation yielding phenomena can in principle deteriorate the surface quality during sheet forming operations. From a fundamental perspective, it is interesting to study this

effect in more detail, since discontinuous yielding has rarely been observed in other multiphase composite-like alloys (e.g. conventional transformation-induced plasticity (TRIP),

dual

phase and duplex stainless steels).

What is the origin of discontinuous plastic yielding in medium Mn steels ?

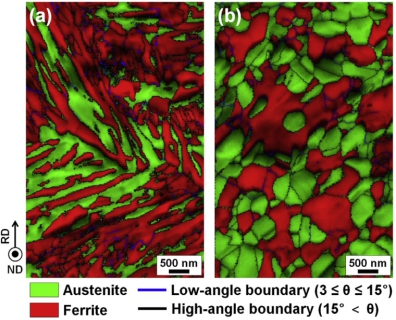

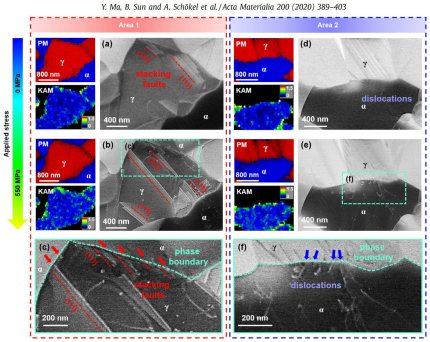

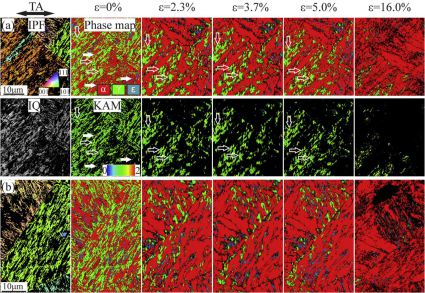

We studied the discontinuous yielding phenomenon in ultrafine austenite-ferrite duplex medium Mn steels and find that medium Mn steels with an austenite matrix (austenite fraction ~65 vol%)

can exhibit pronounced discontinuous yielding. A combination of multiple in situ characterization techniques from macroscopic (a few millimeters) down to nanoscopic scale (below 100 nm) is

utilized to investigate this phenomenon. We observe that both austenite and ferrite are plastically deformed before the macroscopic yield point. In this microplastic regime, plastic

deformation starts in the austenite phase before ferrite yields. The austenite-ferrite interfaces act as preferable nucleation sites for new partial dislocations in austenite and for full

dislocations in ferrite. The large total interface area, caused by the submicron grain size, can provide a high density of dislocation sources and lead to a rapid increase of mobile

dislocations, which is believed to be the major reason accounting for discontinuous yielding in such steels. We simultaneously study the Lüders banding behavior and the local

deformation-induced martensite forming inside the Lüders bands. We find that

grain size and the austenite stability against deformation-driven martensite formation are two important microstructural factors controlling the Lüders band characteristics in terms of the

number of band nucleation sites and their propagation velocity. These factors thus govern the early yielding stages of

medium Mn steels, due to their crucial influence on mobile dislocation generations and local work hardening.

Sun et al - Acta Mater 2019 Macroscopic [...]

PDF-Dokument [7.5 MB]

What is the role of prior austenite grain boundaries and microstructural on the impact toughness of medium Mn steels ?

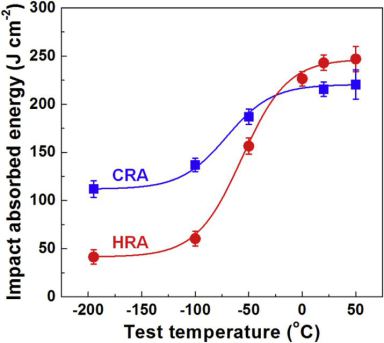

We studied the effects of prior austenite grain boundaries and microstructural morphology on the impact toughness of an annealed Fe-7Mn-0.1C-0.5Si medium Mn

steel for two different types of microstructure states, namely, hot-rolled and annealed specimens and cold-rolled and annealed specimens.

Both types of specimen microstructures had a dual-phase microstructure consisting of retained austenite and ferrite after intercritical annealing at 640°C for 30 min. The phase fractions and

the chemical composition of the retained austenite were almost identical in both types of specimens. However, their microstructural morphology was different. The hot-rolled and annealed

specimens had lath-shaped morphology and the cold-rolled and annealed specimens specimens had globular-shaped morphology. We observed that both types of specimens showed a transition

in fracture mode from ductile and partly quasi-cleavage fracture to intergranular fracture with decreasing impact test temperature from room temperature to 196°C. The hot-rolled and

annealed specimens had higher ductile to brittle transition temperature and lower low-temperature impact toughness compared to the cold-rolled and annealed specimens.

This was due to intergranular cracking in the HRA specimens along prior austenite grain boundaries decorated by C, Mn and P. In the CRA specimen intergranular cracking occurred along the

boundaries of the very fine martensite grains. The results reveal that cold working prior to intercritical annealing promotes the elimination of the solute-decorated boundaries of coarse

prior austenite grains through the recrystallization of martensite prior to reverse transformation, hence improving the low-temperature impact toughness of medium Mn steel.

Acta Materialia 122 (2017) 199

Fe Acta 2016 Han Medium Mn Steel prior a[...]

PDF-Dokument [3.8 MB]

Grain boundary segregation, interfacial spinodal and their relevance for nucleation during solid-solid phase transitions

Grain boundary segregation, embrittlement and phase nucleation in Fe - Mn allyos are interconnected phenomena that have been often treated separately, partly due to limitations of the current models to predict grain boundary segregation in non-ideal solid solutions.

In this project a simple model has been introduced to predict grain boundary segregation in solid solutions by coupling available bulk thermodynamic data with a meanfield description of

the grain boundary character. The model is confronted with experimental results obtained in Fe-Mn alloys analysed by atom probe tomography. This model successfully predicts a first order

transition or a discontinuous jump in the composition of the grain boundary which kinetically implies the formation of spinodal Mn fluctuations that tend to grow further with time within

the segregated region. The increase in solute concentration at the grain boundary leads to an increase of the

enthalpy of the boundary and to its embrittlement at lower temperatures. Once austenite is formed, the amount of segregated solute Mn on the grain boundaries is drastically reduced and the

toughness of the grain boundary is increased.

Acta Materialia 168 (2019) 109-120

Acta 2019 Thermodynamics of grain bounda[...]

PDF-Dokument [4.0 MB]

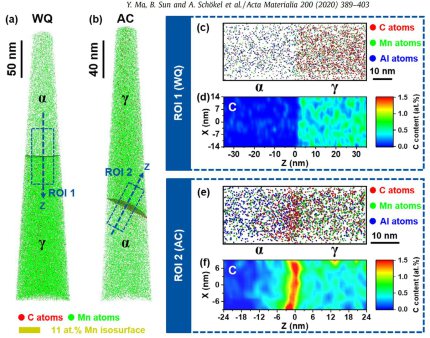

What is the role of phase boundary segregation-induced strengthening and discontinuous yielding in ultrafine-grained duplex medium-Mn steels?

The combination of different phase constituents to realize a mechanical composite effect for superior strength-ductility synergy has become an important strategy in microstructure design in

advanced high-strength steels. Introducing multiple phases in the microstructure essentially produces a large number of

phase boundaries. Such hetero-interfaces affect the materials in various aspects such as dislocation activity and damage formation. However, it remains a question whether the characteristics of phase

boundaries, such as their chemical decoration states, would also have an impact on the mechanical behavior in multiphase steels. Here we reveal a phase boundary segregation-induced strengthening

effect in ultrafine-grained duplex medium-Mn steels. We found that the carbon segregation at ferrite-austenite phase boundaries can be manipulated by adjusting the cooling conditions after

intercritical annealing.

Such phase boundary segregation in the investigated steels resulted in a yield strength enhancement by 100–120 MPa and simultaneously promoted discontinuous yielding. The sharp carbon

segregation at the phase boundaries impeded interfacial dislocation emission, thus increasing the stress required to activate such dislocation nucleation process and initiate plastic

deformation. This observation suggests that the enrichment of carbon at the phase boundaries can enhance the energy barrier for dislocation emission, which provides a favorable condition

for plastic flow avalanches and thus discontinuous yielding. These

findings extend the current understanding of the yielding behavior in medium-Mn steels, and more importantly, shed light on utilizing and manipulating phase boundary segregation to improve the

mechanical performance of multiphase metallic materials.

Acta Materialia 200 (2020) 389

Acta Mater 2020 Yan Ma segregation-induc[...]

PDF-Dokument [5.6 MB]

Do medium Mn steels reveal microstructural size effects ?

Medium Mn steels containing reverted nanoscale austenite islands or films dispersed in a martensitic or ferritic matrix show excellent strength, ductility

and toughness. The underlying microstructural mechanisms responsible for these improvements are not yet fully understood, but are observed to be strongly connected to the island or film size of

the (reverted) nanoscale austenite. Two main micromechanical effects are conceivable in this context:

(i) interaction of reverted nanoscale austenite with microcracks from the matrix (crack blunting or arresting);

and

(ii) deformation-induced phase transformation of reverted nanoscale austenite to martensite (TRIP effect).

We studied the latter phenomenon. To investigate size effects on reverted nanoscale austenite transformation independent of other factors that can influence austenite stability (composition,

crystallographic orientation, defect density, surrounding phase, etc.), a model (TRIP-maraging steel) microstructure is designed with support from diffusion simulations (using DICTRA modeling)

to have the same, homogeneous chemical composition in all reverted nanoscale austenite grains. Characterization is conducted by in-situ tension and bending experiments in conjunction with

high-resolution electron backscatter diffraction mapping and scanning electron microscopy imaging, as well as post-mortem transmission electron microscopy and synchrotron X-ray diffraction

analysis. Results reveal an unexpected “smaller is less stable” effect due to the size-dependent competition between mechanical twinning and deformation-induced

phase transformation.

Acta Materialia 79 (2014) 268

Acta Materialia 79 (2014) 268 reversion [...]

PDF-Dokument [2.7 MB]

Is the martensite to austenite reversion in medium Mn steels diffusive or displacive ?

We studied the transition from diffusive to displacive austenite reversion mechanisms in a medium Mn steel, also considering the effect of heating rate

on austenite reversion behavior using a 0.15%C–5%Mn model steel. Austenite reversion temperature first increased gradually with the heating rate owing to the superheating effect and then

remained at a constant temperature above a critical heating rate. In response, the austenite formed by rapid heating exhibited a coarse prior austenite grain structure, indicating the

occurrence of displacive reversion even in low-alloy steel.

ISIJ International, Vol. 53 (2013), No. 12, pp. 2275–2277

ISIJ Austenite reversion diffusion displ[...]

PDF-Dokument [1.3 MB]

ISIJ International, Vol. 53 (2013), No. 7, pp. 1286

ISIJ-austenite reversion 53_1286 Nakada [...]

PDF-Dokument [907.2 KB]

Study of medium Mn steels by a bulk combinatorial design with specific reference to martensite-to-austenite reversion

We studied the effect of local martensite-to-austenite reversion on microstructure and mechanical properties with the aim of designing ductile medium Mn steels. Following a

combinatorial screening with tensile and hardness testing on a matrix of six alloys (0 - 5 wt.% Mn, 0 - 2 wt.% Si, constant 13.5 wt.% Cr and 0.45 wt.% C) and seven martensite tempering

conditions (300 - 500 °C, 0 -30 min), investigations were focussed on martensite-to-austenite reversion during tempering as function of chemical composition and its correlation with the

mechanical properties. While Mn additions promoted austenite formation (up to 35 vol.%) leading to a martensitic-austenitic TRIP steel with optimum mechanical properties (1.5 GPa ultimate

tensile strength and 18 % elongation), Si led to

brittle behaviour despite even larger austenite contents. Combined additions of Mn and Si broadened the temperature range of austenite reversion, but also significantly lowered hardness and

yield strength at limited ductility. These drastically diverging mechanical properties of the probed steels are discussed in light of microstructure morphology, dispersion and

transformation kinetics of the

austenite, as a result of the composition effects on austenite retention and reversion.

Materials Science & Engineering A 582 (2013) 235

Mater Sc Engin A 582 (2013) 235 bulk com[...]

PDF-Dokument [3.8 MB]

Medium Mn steels can have increased resistance to crack propagation

Fatigue failures create enormous risks for all engineered structures, as well as for human lives, motivating large safety factors in design and, thus, inefficient use of

resources. Inspired by the excellent fracture toughness of bone, we explored the fatigue resistance in metastability-assisted multiphase steels. We show here that when steel

microstructures are hierarchical and laminated, similar to the substructure of bone, superior crack resistance can be realized. Our results reveal that tuning the interface

structure, distribution, and phase stability to simultaneously activate multiple micromechanisms that resist crack propagation is key for the observed leap in mechanical response. The

exceptional properties enabled by this strategy provide guidance for all fatigue-resistant alloy design efforts.

Koyama et al., Science 355, 1055–1057 (2017) 10 March 2017

Koyama Science 355 (6329), 1055-1057.pdf

PDF-Dokument [744.3 KB]

What is a spectral TRIP effect in medium Mn steels?

Introduction of interlath reverted austenite is an effective method to design ductile lath medium Mn martensitic steels. The challenge in this concept is that all reverted austenite films have similar mechanical stability, hence, they all undergo transformation-induced plasticity (TRIP) at the same strain level. Here we propose a new thermo-mechanical treatment route to activate the TRIP effect over a broad strain regime and refer to it as ‘spectral TRIP effect’. It aims at spreading the micro-mechanical stability of reverted austenite grains by widening the austenite nucleation barrier in martensite. To validate the proposed thermo-mechanical treatment route, an as-quenched medium-Mn martensitic steel was cold rolled prior to the reversion treatment at 600°C. Microstructure characterization was carried out by electron backscatter diffraction (EBSD) and electron channeling contrast imaging (ECCI). Mechanical tests show that the approach is effective. The spectral TRIP effect improves both, the strength and the ductility due to the well dispersed size distribution and the associated size-dependent deformation and phase transformation behavior of the reverted austenite grains, extending TRIP-related work hardening over a broad strain range.

Acta Materialia 111 (2016) 262 martensit[...]

PDF-Dokument [1.8 MB]

How can nanolaminate transformation-induced plasticity–twinning-induced plasticity medium Mn steels be designed ?

Conventional martensitic medium Mn steels have limited ductility due to insufficient microstructural strain-hardening and damage resistance mecha-

nisms. It was recently demonstrated that the ductility and toughness of martensitic steels can be improved without sacrificing the strength, via partial

reversion of the martensite back to austenite. These improvements were attributed to the presence of the transformation-induced plasticity (TRIP)

effect of the austenite phase, and the precipitation hardening (maraging) effect in the martensitic matrix. However, a full micromechanical understanding of this ductilizing effect requires a

systematic investigation of the interplay between the two phases, with regards to the underlying deformation and damage micromechanisms. For this purpose, in this work, a Fe–9Mn–3Ni–1.4Al–0.01C

(mass%) medium-Mn TRIP maraging steel is produced and heat-treated under different reversion conditions to introduce well-controlled variations in the austenite–martensite

nanolaminate microstructure. Uniaxial tension and impact tests are carried out and the microstructure is characterized using scanning and transmission electron microscopy based techniques

and post mortem synchrotron X-ray diffraction analysis. The results reveal that (i) the strain partitioning between austenite and martensite is governed by a highly dynamical interplay of dislocation

slip, deformation-induced phase transformation (i.e. causing the TRIP effect) and mechanical twinning (i.e. causing the twinning-induced plasticity effect); and (ii) the nanolaminate

microstructure morphology leads to enhanced damage resistance. The presence of both effects results in enhanced strain-hardening capacity and damage resistance, and hence the

enhanced ductility.

Acta Materialia 85 (2015)

Acta Materialia vol 85 (2015) Nanolamina[...]

PDF-Dokument [1.3 MB]

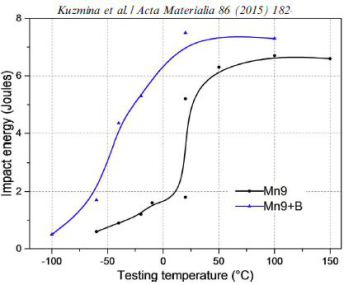

Grain boundary segregation engineering and austenite reversion turn embrittlement into toughness: Example of a 9 wt.% medium Mn steel

We study grain boundary embrittlement in a quenched and tempered Fe–Mn high-purity model martensite alloy using Charpy impact tests and grain boundary characterization by atom probe tomography. We observe that solute Mn directly embrittles martensite grain boundaries while reversion of martensite to austenite at high-angle grain boundaries cleans the interfaces from solute Mn by partitioning the Mn into the newly formed austenite, hence restoring impact toughness. Microalloying with B improves the impact toughness in the quenched state and delays temper embrittlement at 450 °C. Tempering at 600 °C for 1 min significantly improves the impact toughness and further tempering at lower temperature does not cause the embrittlement to return. At higher temperatures, regular austenite nucleation and growth takes place, whereas at lower temperature, Mn directly promotes its growth.

Acta Materialia 86 (2015) 182

Acta Materialia 86 (2015) 182 Kuzmina Gr[...]

PDF-Dokument [1.8 MB]

What is the role of chemical gradients across phase boundaries between martensite and austenite in medium Mn steel ?

Partitioning at phase boundaries of complex steels is important for their properties. We present atom probe tomography results across martensite/austenite interfaces in a

precipitation-hardened maraging-TRIP steel (12.2 Mn, 1.9 Ni, 0.6 Mo, 1.2 Ti, 0.3 Al; at.%). The system

reveals compositional changes at the phase boundaries: Mn and Ni are enriched while Ti, Al, Mo and Fe are depleted. More specific, we observe up to 27 at.% Mn in a 20 nm layer at the phase

boundary. This is explained by the large difference in diffusivity between martensite and austenite. The high diffusivity in martensite leads to a Mn flux towards the retained austenite. The low

diffusivity in the austenite does not allow accommodation of this flux. Consequently, the austenite grows with a Mn composition given by local equilibrium. The interpretation is based on

DICTRA and mixed-mode diffusion calculations (using a finite interface mobility).

Acta Materialia 59 (2011) 364–

Acta Materialia 59 (2011) 364 atom probe[...]

PDF-Dokument [2.3 MB]

How to tune the fraction and stacking fault energy of reverted austenite in medium Mn steels

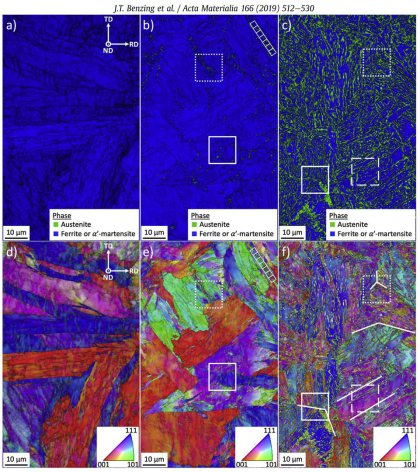

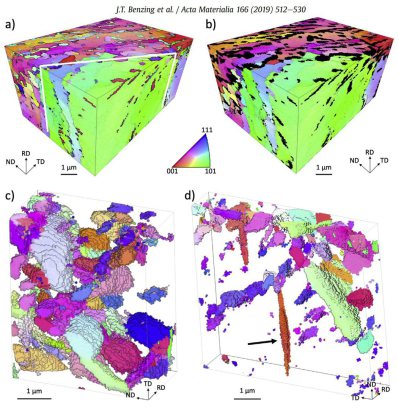

In this joint project a medium-Mn steel (Fe-12Mn-3Al-0.05C wt%) was designed using Thermo-Calc simulations to balance the fraction and stacking fault energy of reverted austenite. Intercritical

annealing for 0.5, 8 and 48 h was carried out at 585 C to investigate the microstructural evolution. X-ray diffraction (XRD), electron backscatter diffraction (EBSD), 3-dimensional EBSD,

energy-dispersive spectroscopy via scanning-transmission electron microscopy (STEM-EDS) and atom probe tomography (APT) enable characterization of phase fraction, grain area, grain morphology and

alloy partitioning. An increase in annealing time

from 0.5 h to 48 h increases the amount of ultrafine-grained (UFG) reverted austenite from 3 to 40 vol %. EBSD and TEM reveal multiple morphologies of UFG austenite (equiaxed, rod-like and

plate-like). In addition, most of the remaining microstructure consists of recovered a0-martensite that resembles the

cold-rolled state, as well as a relatively small fraction of UFG ferrite (i.e., only a small amount of martensite recrystallization occurs). Multi-scale characterization results show that the

location within the cold-rolled microstructure has a strong influence on boundary mobility and grain morphology during austenite reversion. Results from APT reveal Mn-decoration of

dislocation networks and low-angle lath boundaries in the recovered a0-martensite, but an absence of Mn-decoration of defects in the vicinity of austenite grains, thereby promoting

recovery. STEM-EDS and APT reveal Mn depletion zones in the ferrite/recovered a0-martensite near austenite boundaries, whereas gradients of C and Mn copartitioning are visible within some of the

austenite grains after annealing for 0.5 h. Relatively flat C-enriched austenite boundaries are present even after 8 h of annealing and indicate certain boundaries

possess low mobility. At later stages the growth of austenite followed the local equilibrium (LE) model such that the driving force between two equilibrium phases moves the mobile interface, as

confirmed by DICTRA simulations (a Thermo-Calc diffusion module). The sequence of austenite reversion is: (i) for-

mation of Mn- and C-enriched face-centered-cubic nuclei from decorated dislocations and/or particles; (ii) co-partitioning of Mn and C and (iii) growth of austenite controlled by the LE

mode.

Acta Materialia 166 (2019) 512

Acta Materialia 2019 austenite reversion[...]

PDF-Dokument [1.1 MB]

How does the competition between formation of carbides and reversed austenite work during tempering of a medium-manganese steel?

To answer this question we investigated the thermodynamics and kinetics of carbide precipitation in a cold-rolled Fe-7Mn-0.1C-0.5Si medium manganese steel during low temperature tempering. The

material was annealed up to

24 h at 450°C in order to follow the kinetics of precipitation. Using thermodynamics and kinetics simulations, we predicted the growth of M23C6 carbides according to the local-equilibrium

negligible partition (LENP) mode where carbide growth is controlled by the diffusion of carbon, while maintaining

local chemical equilibrium at the interface. Atom-probe tomography (APT) measurements performed on samples annealed for 1, 6 and 24 h at 450°C confirmed that LENP is indeed the mode of carbide

growth and that Mn segregation is necessary for the nucleation. Additionally, we observed the heterogeneous nucleation of transition carbides with a carbon content between 6 and 8 at% at

segregated dislocations and grain boundaries. We describe these carbides as a complex face-centered cubic transition carbide type (CFCC-TmC phase) obtained by the supersaturation of the FCC

structure by carbon that will act as precursor to the more stable gamma-M23C6 carbide that forms at the dislocations and grain boundaries. The results suggest that the addition of carbon

does not directly favor the formation of austenite, since Mn is consumed by the formation of the carbides and the nucleation of austenite is thus retarded to later stages of tempering as

every FCC nucleus in the initial stages of tempering is readily converted into a carbide nucleus. We propose the following sequence of transformation: (i) carbon and Mn co-segregation

to dislocations and grain boundaries; (ii) formation of FCC transition carbides; (iii) growth controlled according to the LENP mode and (iv) austenite nucleation and growth.

What are linear complexions in medium Mn steels?

For 5000 years, metals have been mankind’s most essential materials owing to their ductility and strength. Linear defects called dislocations carry atomic shear steps, enabling their

formability. We report chemical and structural states confined at dislocations. In a body-centered cubic medium Mn Fe–9 atomic percent Mn alloy, we found Mn segregation at dislocation cores

during heating, followed by formation of face-centered cubic regions but no further growth. The regions are in equilibrium with the matrix and remain confined to the dislocation cores with

coherent interfaces.The phenomenon resembles interface-stabilized

structural states called complexions. A cubic meter of strained alloy contains up to a light year of dislocation length, suggesting that linear complexions could provide opportunities to

nanostructure alloys via segregation and confined structural states.

SCIENCE 1080 4 SEPTEMBER 2015 • VOL 349 ISSUE 6252 sciencemag.org

Linear Complexions Science vol 349 (2015[...]

PDF-Dokument [1.5 MB]

PDF-Dokument [2.3 MB]