Nanosteels and Advanced High-Strength Steels

Why are Advanced High-Strength Steels important?

Steels are backbone materials of civilization since more than 3000 years. They retrieve their properties not from expensive chemical compositions but rather from complex nano- and microstructures.

They cover a wider spectrum of properties than any other material.

On these pages we have cast some recent progress in the understanding of the nano- and microstructure–property relations of advanced high-strength steels into a view main points.

See the full report here:

What are Advanced High-Strength Steels important?

Advanced High-Strength Steels constitute a class of high-strength, formable steels that are designed mainly as sheet products for the transportation sector.

They have often complex and hierarchical microstructures consisting of ferrite, austenite, bainite, or martensite matrix or of duplex or even multiphase mixtures of these constituents, sometimes enriched with precipitates. This complexity makes it challenging to establish reliable and mechanism-based microstructure–property relationships.

We present here some recent progress in microstructures and alloy design, placing attention on the deformation and strain hardening mechanisms of steels that utilize complex dislocation substructures, nanoscale precipitation patterns, deformation-driven transformation, and twinning effects. Recent developments on microalloyed nanoprecipitation hardened and press hardening steels are also reviewed. Besides discussing their microstructures and properties, features such as hydrogen embrittlement and damage formation are also evaluated. We also present progress in characterization and modeling techniques applied to these steels. Emerging topics such as machine learning, through-process simulation, and additive manufacturing are also presented.

What are nanosteels ?

Steels are generally nanostructured alloys. However, on this specific website I present some recent developments which make use of well-designed nano-precipitate and nano-twinned

systems.

Most of the examples are based on the maraging (= martensite + ageing) concept and some examples make use of fine precipitates in a ferritic matrix. The other set of examples uses a compund-type

microstructure consistening of recrystallized soft grains and hard nanotwinned grains, based on an idea developed in the group of K. Lu at CAS.

Ultrahigh number density of nanoprecipitates in steel

doi:10.1038/nature22032

Ultrastrong steel via minimal lattice mi[...]

PDF-Dokument [6.2 MB]

High-performance steels are required for lightweight design strategies, savety, high strength structure design and advanced energy applications. Maraging steels, combining a martensite

matrix with nanoprecipitates, are a class of high-strength materials with the potential for matching these demands. Their superior strength originates from semi-coherent precipitates,

which unavoidably exhibit a heterogeneous distribution that creates large coherency strains, which in turn may promote crack initiation under load. In this report we present a novel

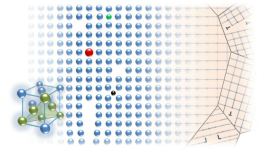

and quite counterintuitive strategy for the design of ultrastrong steel alloys by high-density nanoprecipitation with minimal lattice misfit. We found that these highly dispersed,

fully coherent precipitates (that is, the crystal lattice of the precipitates is almost the same as that of the surrounding matrix), showing very low lattice misfit with the matrix and

high anti-phase boundary energy, strengthen alloys without sacrificing ductility. Such low lattice misfit (0.03 ± 0.04 per cent) decreases the nucleation barrier for precipitation,

thus enabling and stabilizing nanoprecipitates with an extremely high number density (more than 10^24 per

cubic metre) and small size (about 2.7 ± 0.2 nanometres).

The minimized elastic misfit strain around the particles does not contribute much to the dislocation interaction, which is typically needed for strength increase. Instead, our strengthening mechanism exploits the chemical ordering effect that creates backstresses (the forces opposing deformation) when precipitates are cut by dislocations. We create a class of steels, strengthened by Ni(Al,Fe) precipitates, with a strength of up to 2.2 gigapascals and good ductility (about 8.2 per cent). The chemical composition of the precipitates enables a substantial reduction in cost compared to conventional maraging steels owing to the replacement of the essential but high-cost alloying elements cobalt and titanium with inexpensive and lightweight aluminium. Strengthening of this class of steel alloy is based on minimal lattice misfit to achieve maximal precipitate dispersion and high cutting stress (the stress required for dislocations to cut through coherent precipitates and thus produce plastic deformation), and we envisage that this lattice misfit design concept may be applied to many other metallic alloys.

Nanostructured maraging steels by additive manufacturing

Acta Materialia 129 (2017) 52-60

Acta Mater 2017 Additive Manufacturing M[...]

PDF-Dokument [2.4 MB]

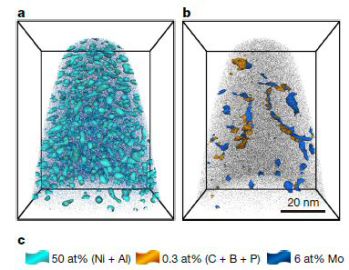

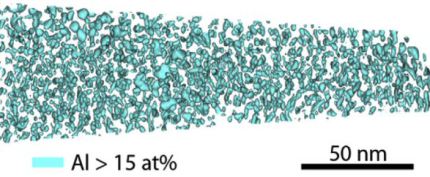

Owing to the effect of the layer-by-layer build-up of additively manufactured parts, the so deposited material experiences a cyclic re-heating in the form of a sequence of temperature pulses. In the current work, this “intrinsic heat treatment (IHT)” was exploited in this project to induce the precipitation of NiAl nanoparticles in an Fe-19Ni-xAl (at%) model maraging steel, a system known for rapid clustering. We used Laser Metal Deposition (LMD) to synthesize compositionally graded specimens. This allowed for the efficient screening of effects associated with varying Al contents ranging from 0 to 25 at% and for identifying promising concentrations for further studies. Based on the existence of the desired martensitic matrix, an upper bound for the Al concentration of 15 at% was defined. Owing to the presence of NiAl precipitates as observed by Atom Probe Tomography (APT), a lower bound of 3e5 at% Al was established. Within this concentration window, increasing the Al concentration gave rise to an increase in hardness by 225 HV due to an exceptionally high number density of 10^25 NiAl precipitates per m^3, as measured by APT. This work demonstrates the possibility of exploiting the IHT of the LMD process for the production of samples that are precipitation strengthened during the additive manufacturing process without need for any further heat treatment.

Chemical boundary engineering as a pathway for the design of lean, ultrastrong and ductile nanosteels

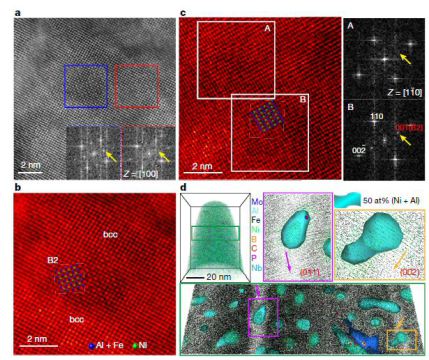

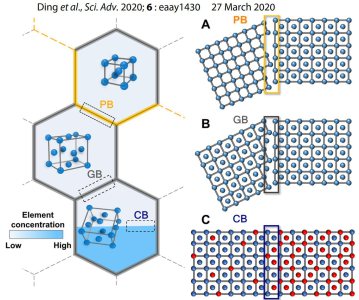

Chemical boundary engineering in steels refers to a microstructure design approach based on chemical instead of structural interfaces. Such chemical boundaries (CBs) can be used here to architect novel microstructures that can act on the local phase transformation response of the material. CBs represent

a very sharp chemical discontinuity inside a continuous lattice region, as shown in the Figure. In the current steels design approach pursued here each CB is the residue of a former phase boundary with its element partitioning retained upon removing the local change in crystal structure. Once formed, CBs act as strong barriers against dislocation motion. The original paper can be found here.

Ding et al., Sci. Adv. 2020; 6 - March 2020

Science Advances 2020 Chemical boundary [...]

PDF-Dokument [6.2 MB]

Core-shell nanoparticles in steels

Scientific Reports | 7:42547 | DOI: 10.1038/srep42547

Scientific Reports 7 - 42547 Core-shell [...]

PDF-Dokument [2.2 MB]

Manipulating structure, defects and composition of a material at the atomic scale for enhancing its physical or mechanical properties is referred to as nanostructuring. Here, by combining

advanced microscopy techniques, we unveil how formation of highly regular nano-arrays of nanoparticles doubles

the strength of an Fe-based alloy, doped with Ti, Mo, and V, from 500 MPa to 1 GPa, upon prolonged heat treatment. The nanoparticles form at moving heterophase interfaces during cooling from

the high-temperature face-centered cubic austenite to the body-centered cubic ferrite phase. We observe MoC and TiC nanoparticles at early precipitation stages as well as core-shell

nanoparticles with a Ti-C rich core and a Mo-V rich shell at later precipitation stages. The core-shell structure hampers particle coarsening, enhancing the material’s strength. Designing

such highly organized metallic core-shell nanoparticle arrays provides a new pathway for developing a wide range of stable nano-architectured engineering metallic alloys with drastically

enhanced properties.

Nanosteel with high Young's modulus

Scientific Reports | 7: 2757 | DOI:10.1038/s41598-017-02861-3

Springer_et_al-2017-Scientific_Reports.p[...]

PDF-Dokument [2.7 MB]

Materials and Design 112 (2016) 131–139

[16Bar] Combinatorial screening of the m[...]

PDF-Dokument [1.9 MB]

Acta Materialia 118 (2016) 187

Mechanical properties High Modulus Steel[...]

PDF-Dokument [1.7 MB]

Structural material development for lightweight applications aims at improving the key parameters strength, stiffness and ductility at low density, but these properties are typically mutually exclusive.

Here we present how we overcome this trade-off with a new class of nano-structured steel – TiB2 composites

synthesised in-situ via bulk metallurgical spray-forming. Owing to the nano-sized dispersion of the TiB2 particles of extreme stiffness and low density – obtained by the in-situ formation with

rapid

solidification kinetics – the new material has the mechanical performance of advanced high strength steels, and a 25% higher stiffness/density ratio than any of the currently used high strength

steels, aluminium, magnesium and titanium alloys. This renders this High Modulus Steel the first density reduced, high stiffness, high strength and yet ductile material which can be

produced on an industrial scale. Also ideally suited for 3D printing technology, this material addresses all key requirements for high performance and cost effective lightweight design.

Croosover nanosteel by combining maraging, reversion and TRIP

ADVANCED ENGINEERING MATERIALS 2009, 11, No. 7

Adv Engin Mate _2009 Ultrahigh Strength [...]

PDF-Dokument [1.7 MB]

Scripta Materialia 60 (2009) 1141 maragi[...]

PDF-Dokument [342.1 KB]

In this project, we devise a novel class of nano-precipitation hardened ductile high strength martensitic and austenitic-martensitic steels (up to 1.5 GPa strength). The alloys are

characterized by a low carbon content (0.01 wt% C),

9–15 wt% Mn to obtain different levels of austenite stability, and minor additions of Ni, Ti, and Mo (1–2 wt%). The latter are required for creating precipitates during aging heat

treatment. Hardening in these materials is realized by combining the TRIP effect with a maraging treatment [transformation-induced

plasticity (TRIP); maraging: martensite aging through thermally stimulated precipitation of particles]. The TRIP mechanism is based on the deformation-stimulated

athermal transformation of metastable austenite (face centered cubic

Fe–Mn phase) into martensite (metastable body centered cubic or orthorhombic Fe–Mn phase) and the resulting matrix and martensite plasticity required to accommodate the transformation

misfit. The maraging treatment is based

on hardening the heavily strained martensite through the formation of small intermetallic precipitates (of the order of several nanometers). These particles act as highly

efficient obstacles against dislocation motion through the Orowan and Fine-Kelly mechanisms enhancing the strength of the material.

Acta Materialia 81 (2014) 487 Nano-twin [...]

PDF-Dokument [2.1 MB]

Acta Mater nanotwinned cyclic loaded sta[...]

PDF-Dokument [7.2 MB]

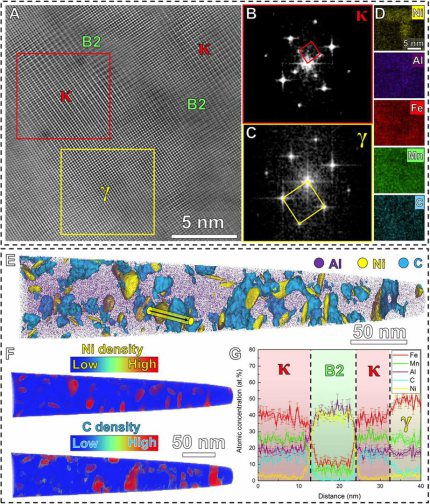

Ultrastrong lightweight compositionally complex steels via dual-nanoprecipitation

The design of steels with high strength, toughness, and ductility combined with low mass density is an important task for saving energy and reducing emissions at maintained safety levels in

multiple transportation applications. For example, reducing a vehicle’s weight translates linearly to a corresponding reduction in fuel consumption, with a rule of thumb value of 0.5 liters less

fuel per 100 kg of weight reduction. Although other lightweight materials, e.g., Al-alloys, Mg-alloys,

and carbon fiber composites, are available or under development, the unique combination of absolute strength, specific strength, ductility, toughness, and cost-effectiveness makes advanced

lightweight Fe-based steels particularly attractive for future key engineering applications.

In this context, the Fe-Mn-Al-C system has gained much attention since the addition of Al into the Fe-Mn-C system is effective to achieve both up to ~10% weight reduction and improved strength and

ductility compared to conventional steels. More specifically, Fe-Mn-Al-C steels with austenitic [face-centered cubic (FCC)] solid solution matrix and nanosized L'12 (ordered FCC) kappa-carbides reach

a tensile strength of ~1190 MPa (specific tensile strength of 183 MPa·cm3 g−1) at an elongation of ~30% under tensile loading. However, the shearing of the coherent kappa-carbides at high

stresses leads to local strain softening, which can cause strain localization.

Also, at grain boundaries, the Kappa-carbides become incoherent, promoting crack initiation, which leads to embrittlement, particularly at high Al and C contents (2). Thus, for further enhancing the

mechanical properties, non-shearable incoherent B2 (ordered body-centered cubic) particles, instead of kappa-carbides, have been introduced into Fe-Mn-Al-C–based austenitic steels. The

uniformly distributed hard B2 particles enable pronounced local strain hardening, since the dislocations must bow out and bypass them, leaving additional dislocation loops around the particles

behind, an effect referred to as Orowan strengthening. This mechanism leads to very high specific strength values of up to 233 MPa·cm3 g−1 for an alloy (referred to as high–specific strength steels

(HSSSs)) with 22 vol. % of B2 precipitates. Higher strength values require larger volume fractions of B2 particles, yet only at a significant expense of ductility, due to the intrinsically

brittle nature of the B2 intermetallic compound.

Because of these limitations of the existing alloy design concepts, we introduce here a new approach in which we strengthen a low-density solid solution matrix simultaneously by a

dual-nanoprecipitation system containing both kappa-carbides and B2 particles. Since the conventional thermodynamic working point is not accessible to realize this dual-precipitation strategy, we

designed a low-density (6.6 g/cm3) steel-type alloy, which uses merits of the recently introduced multi–principal element approach referred to as compositionally complex alloys (CCAs) or high-entropy

alloys (HEAs). More specifically, we propose here a new class of compositionally complex steels (CCSs) consisting of five principal elements including C in nonequiatomic ratios with Fe holding

the highest atomic fraction [48 atomic % (at. %)], and each element has an atomic fraction of no less than 5 at. %.