Non-Equiatomic High-Entropy Alloys: Compositionally Complex Alloys with High Strength and Ductility

What are non-equiatomic high-entropy alloys?

Conventional alloy design over the past centuries has been constrained by the concept of one or two prevalent base element. As a breakthrough of this restriction, the concept of high-entropy alloys (HEAs) containing multi-principal elements has drawn great attention over the last 15 years due to the numerous opportunities for investigations in the huge unexplored compositional space of multi-component alloys.

A large number of studies in this field have been motivated by the original HEA concept which suggested that achieving maximized configurational entropy via the equiatomic ratios of multiple principal elements could stabilize single-phase massive solid solution phases.

However, an increasing number of studies revealed that formation of single-phase solid solutions in HEAs shows a weak dependence on maximization of the configurational entropy through equiatomic ratios of elements, and it was even found that maximum entropy is not the most essential parameter when aiming at the design of multi-component alloys with superior properties. These findings have recently encouraged efforts to relax both, the unnecessary restrictions on the equiatomic ratio of multiple principal elements and also on the formation of single-phase solid solutions. In this context, non-equiatomic HEAs with single-, dual- or multi-phase structures have been proposed recently to explore the flexibility of HEAs design and overcome the limitations of the original HEA design concept. Also, deviating from the equimolar composition rule facilitates identifying compositions which allow avoiding the often brittle intermetallic phases.

Brief overview on strong and ductile non-equiatomic high-entropy alloys. JOM, Aug. 2017

Li 2017 JOM 2017 overview Non-Equiatomic[...]

PDF-Dokument [1.5 MB]

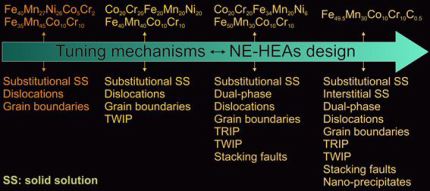

In this overview paper we present a brief review on recent developments in the field of strong and ductile non-equiatomic high-entropy alloys (HEAs). The materials reviewed are mainly based on massive transition-metal solute solutions and exhibit a broad spectrum of microstructures and mechanical properties. Three relevant aspects of such non-equiatomic HEAs with excellent strength–ductility combination are addressed in detail, namely phase stability-guided design, controlled and inexpensive bulk metallurgical processing routes for appropriate microstructure and compositional homogeneity, and the resultant microstructure–property relations. In addition to the multiple principal substitutional elements used in these alloys, minor interstitial alloying elements are also considered. We show that various groups of strong and ductile HEAs can be obtained by shifting the alloy design strategy from single-phase equiatomic to dual- or multiphase non-equiatomic compositional configurations with carefully designed phase instability. This design direction provides ample possibilities for joint activation of a number of strengthening and toughening mechanisms. Some potential research efforts which can be conducted in the future are also proposed.

What is the thermodynamic background for designing non-equiatomic high-entropy alloys?

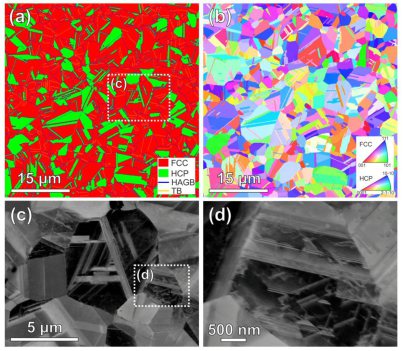

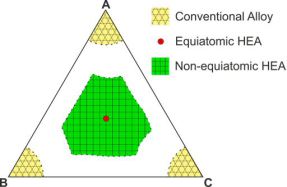

Thermodynamic investigations of non-equiatomic HEAs showed that the configurational entropy curve of these alloys is rather flat, indicating that a wide range of compositions aside from the equiatomic configuration assume similar entropy values. As schematically illustrated in the Figure, compared to the conventional alloys with one or two principal elements plus minor alloying components, and equiatomic HEAs with equimolar ratios of all alloy elements, the non-equiatomic HEAs greatly expand the compositional space that can be probed. Indeed, recent studies have revealed that outstanding mechanical properties exceeding those of equiatomic HEAs can be achieved by non-equiatomic alloys. As one of the possible pathways, a novel type of transformation-induced plasticity-assisted dual-phase (TRIP-DP) HEAs was developed. The two constituent phases in the alloy, i.e., the face-centered cubic (FCC) matrix and the hexagonal close-packed (HCP) phase, are compositionally equivalent and thus can be both referred to as high-entropy phases. This leads to a significantly improved strength-ductility combination compared to the corresponding equiatomic HEAs mainly due to the combination of massive solid-solution strengthening and the TRIP effect. The above findings indicate clearly that expanding the HEA design concept to non-equiatomic compositions has a great potential in pursuing more compositional opportunities for designing novel materials with exceptional properties.

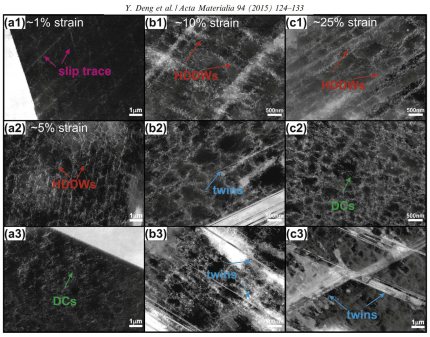

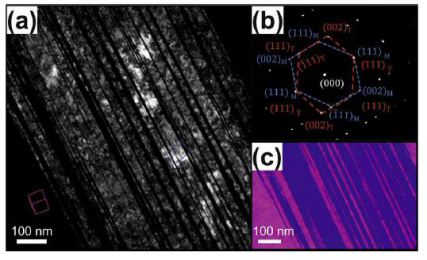

Here we introduce a non-equiatomic Fe40Mn40Co10Cr10 high-entropy alloy. The microstructure at different processing stages revealed a single homogeneous fcc phase as shown by XRD, EBSD, TEM and APT. The mechanical properties at room temperature were investigated by tensile testing and DIC. To understand the

mechanical properties, the deformed substructure at specific strain regions was further revealed by ECCI. We observed that the materials undergoes deformation-driven mechanical twinning (TWIP effect)

Acta Materialia 94 (2015) 124 Twinning I[...]

PDF-Dokument [1.4 MB]

Processing of bulk non-equiatomic high-entropy alloys

For the 3d transition metal HEAs, well-established bulk metallurgical processes are available to synthesize high-quality alloy sheets when the thermomechanical processing parameters are controlled

in a proper way. In our group we use a vacuum induction furnace to melt and cast the various transition metal HEAs. Except for the traditional casting setups, the recently developed combinatorial

approach, referred to as rapid alloy prototyping (RAP), can also be employed towards a rapid trend screening of suited alloy compositions. The RAP technique enables synthesis of five different alloys

with tuned compositions of an alloy system in one operation by using a set of five copper molds which can be moved stepwise inside the furnace.

In as-cast condition, the multiple principal elements are typically not homogeneously distributed in the bulk HEAs with their coarse dendritic microstructure owing to classical Scheil segregation

although X-ray diffraction (XRD) may suggest single- or dual-phase structures. Following casting, alloy plates are cut from the cast blocks and hot-rolled at 900 ℃ with a total thickness reduction of

50% to remove the dendritic microstructure and possible inherited casting defects. The hot-rolling temperature can be adjusted to higher values depending on the specific alloy compositions. Often,

even the hot-rolled HEAs show still some retained compositional inhomogeneity. The hot-rolled alloy sheets are thus homogenized at 1200 ℃ for more than 2 h followed by water-quenching. The

homogenization time should be extended according to the dimensions of the alloys sheets, i.e., the larger the alloy sheets, the longer the homogenization time. The homogenized HEA sheets generally

show homogeneous distribution of the multiple principal elements and no cracks or pores. For HEAs containing a high amount of Mn (e.g. >10 at. %), however, there would be a few inclusions enriched

in Mn which are very hard to be removed even with long-term homogenization.

TRIP Dual-Phase High-Entropy Alloy

Dual-phase high-entropy alloys (DP-HEAs) with transformation induced plasticity (TRIP) have an excellent strength-ductility combination. To reveal their strain-rate sensitivity and hence

further understand the corresponding deformation mechanisms, we investigated the tensile behavior and microstructural evolution of a typical TRIP-DP-HEA (Fe50Mn30Co10Cr10, at. %) under

different strain rates (i.e., 5 × 10−3 s−1, 1 × 10−3 s−1, 5 × 10−4 s−1 and 1 × 10−4 s−1) at room temperature. The strain rate range was confined to this regime in order to apply the digital

image correlation technique for probing the local strain evolution during tensile deformation at high resolution and to correlate it to the microstructure evolution. Grain size effects of

the face-centered cubic

(FCC) matrix and the volume fractions of the hexagonal-close packed (HCP) phase prior to deformation were also considered. The results show that within the explored strain rate regime the

TRIP-DP-HEA has a fairly low strain rate sensitivity parameter within the range from 0.004 to 0.04, which is significantly lower than that of DP and TRIP steels. Samples with varying grain

sizes (e.g., ∼2.8 and 38 µm) and starting HCP phase fractions (e.g., ∼25 and 72%) at different strain rates show similar deformation mechanisms, i.e., dislocation plasticity and

strain-induced transformation from the FCC matrix to the HCP

phase. The low strain rate sensitivity is attributed to the observed dominant displacive transformation mechanism. Also, the coarse-grained alloy samples with a very high starting HCP phase

fraction (∼72%) prior to deformation show very good ductility with a total elongation of ∼60%, suggesting that both, the initial and the transformed HCP phase in the TRIP-DP-HEA are ductile

and deform further via dislocation slip at the different strain rates which were probed.

Frontiers Materials 2018 TRIP-Assisted D[...]

PDF-Dokument [5.5 MB]

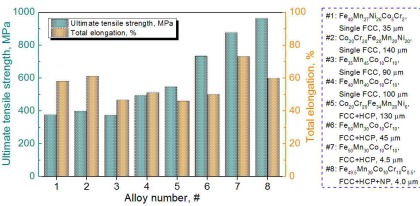

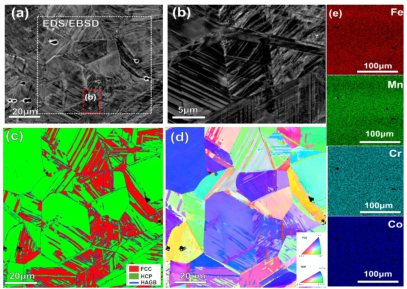

Interstitally alloyed non-equiatomic high-entropy alloys

Further progress along HEAs and dual phase (DP)-HEAs design pathway lead next to a new type of interstitially alloyed DP-HEA (DP-iHEA). The new interstially alloyed DP-iHEA showed further substantially improved strength while maintaining the excellent ductility of the DP-HEAs. This behavior was attributed to the fact that the DP-iHEAs unify all known strengthening mechanisms in one bulk material, e.g., massive interstitial and substitutional solid solution, the TRIP effect, twinning-induced plasticity (TWIP), multiple phases, nano-precipitates, the evolution of complex dislocation substructures due to the low stacking fault energy and grain boundaries.

Why can we and why should we deviate from equiatomic compositions in the design of High and Medium Entropy Alloys?

Developing massive equi-atomic solid solutions is not always the best approach for alloy design. There are several reasons to relax the rather tight constraint of using equi-atomic solid solutions:

1)

The high entropy design rules can be modified to additionally consider interstitial alloying elements, specifically solute C. Interstitial elements, specifically C and N, offer very interesting

alloying options with respect to stabilizing fcc solid solutions as is also expressed by their effect on the VEC. Similar aspects apply to B and even H (yes, as an alloy element). Equiatomic

fractions of C, N or B lead to carbides, nitrides and borides, hence, the equiatomic composition rule makes not so much sense as the main aim and art lies in solid solutiun blending.

2)

A second design idea, deviating from the classical multi-component concept, lies in using relatively lean and non-equiatomically portioned compositions. This is due to the fact that in many

transition metal alloy solid solutions the shape of the configurational entropy as a function of chemical composition assumes a relatively flat and compositionally wide plateau. This means that the

entropy curve has a weak maximum and no steep changes, except for the case of very small concentrations. This fact suggests that entropy-based stabilization of massive solid solutions can also

be achieved for non-equiatomic quinary and quaternary alloy compositions. This modifies the original high entropy alloying concept, where none of the alloying elements was meant to

dominate, into a class of e.g. Fe-based or Ni-based or Ti- based materials.

3)

Beyond the argument associated with the flat entropy curve there are other good reasons for designing compositionally simplified high entropy alloys: An obvious motive lies in reducing alloying costs. Any material that is being designed and meant to be used for specific applications must pass the critical test whether the respective alloying elements and their quantities are indeed required to reach a design target or not. If not, their respective alloying content can be reduced. Examples are typical bounds known for established commercial alloys such as a certain Cr and Mo content in stainless steels for achieving sufficient pitting and corrosion resistance; specific values of Ni and Al in superalloys required to arrive at the characteristic matrix – precipitate structure; a certain Cu content for precipitating Guinier-Preston zones in age hardening aluminum alloys; or a minimum required Nb or Ta content to stabilize elastically compliant bcc Ti alloys. In all these metallurgical examples the respective alloying elements are only added to the content that is required for achieving the aims described, but the alloying content is not increased beyond these values if not serving a specific thermodynamic, kinetic or property function. However, in cases where a near-maximum value of the configurational entropy can be realized at smaller alloying content, i.e. before reaching an equiatomic composition, no need exists to alloy further. In other words the presence of a long and flat compositional entropy plateau enables to exploit a wider mixing range and less consumption of expensive alloying ingredients when designing high entropy alloys.

4)

Another issue in realizing homogeneous massive crystalline solid solutions is not the maximization of the entropy but rather the avoidance of intermetallic phases. When aiming at stabilizing a single phase compositionally complex material it is from a thermodynamic standpoint more plausible to analyze the likelihood of intermetallic compounds in the multicomponent phase diagram rather than only analyzing the configurational entropy. It was recently observed that the entropy-maximized 25% equiatomic quaternary FeMnCoCr alloy (being close to the well-known Cantor alloy) surprisingly leads to a complex multiphase microstructure containing several intermetallic phases while the non-equiatomic material Fe40Mn10Co10Cr produces a homogeneous fcc single phase. This shows that a high entropy contribution to the stabilization of the matrix alone is often not sufficient to over-compensate enthalpy advantages of competing intermetallic phases. This might be also the reason why truly single phase high entropy phases have been realized only for a few compositions so far. Introducing a non-equiatomic mixing rule would provide a much larger compositional space for synthesizing high entropy alloys without intermetallic phases.

5)

Another set of advantages associated with lean multi-component compositions is a practical one, such as reducing variations in vapor pressure typically occurring in multi-component systems, less

segregation and improved casting properties.

6) A further aspect that should be realized is that XRD, EBSD and atom probe tomography analysis increasingly reveals that many of the high entropy alloys that have been studied so far are actually

not single phase materials but often contain intermetallic phases. A well investigated exception from this is the multi-component yet single phase fcc Cantor alloy FeMnNiCoCr. The occurrence of one

or often more intermetallic phases, sometimes with nanoscopic size or at grain boundaries, is not only a thermodynamic or kinetic issue. The presence of intermetallic phases typically deteriorates

mechanical key properties such as ductility, fatigue resistance and toughness. Alloys containing intermetallic phases, therefore, often reveal inferior properties compared to corresponding

single-phase alloys of similar, yet non- equiatomic composition. An additional point supporting non-equiatomic multi-component alloys in the form of high entropy steels is to better exploit fcc phase

stabilization and strain hardening effects associated with interstitial elements, specifically C which has been well studied in the context of TWIP steel systems.

7)

Another recently observed effect is that strain hardening in HEAs can come from cluster formation (and not from maximized solid solution), hence, also suggesting to relax the equiatomic

composition rule.

8)

For improved strain hardening such as TWIP and TRIP it makes more sense to optimize alloy composition for a specific range of the stacking fault energy and not for maximum entropy. The discovery of

several very strong and ductile TWIP and TRIP HEAs underpin this argument.

Developing Twinning Induced Non-Equiatomic High Entropy Alloys

In this paper we introduce a liquid metallurgy synthesized, non-equiatomic Fe40 Mn40 Co10 Cr10 high entropy alloy that is designed to undergo mechanically-induced twinning upon deformation at room temperature.

Acta Materialia 94 (2015) 124 Twinning I[...]

PDF-Dokument [1.4 MB]

Alloy Design Considerations for TWIP High Entropy Alloys

Our TWIP High Entropy Alloy design approach is based on the following considerations: the stacking fault energy of the equiatomic FeMnNiCoCr alloy was determined to be 25 mJ/m2 using a combination of density functional theory (DFT) calculations and X-ray diffraction (XRD) experiments. Reducing the Ni content would lower the stacking fault energy and increase the potential applicability of the alloy due to the decreased alloying contents and costs. However, the four component alloy system FeMnCoCr in absence of Ni (i.e. Fe25Mn25Co25Cr25) develops a multi-phase microstructure with a sigma phase rich in Cr. The Cr rich sigma phase has been observed before in several HEA systems such as FeNiCoCr, Co0.5CrFeMn1.5Ni, FeNiCoCr2, often when Cr is present along with Ni and Co.

Our recent observations demonstrate that equi-atomicity is not an essential requirement to ensure a single phase microstructure. Thus, to avoid the sigma phase and achieve a single fcc phase microstructure, we introduce the Fe40Mn40Co10Cr10 alloy with reduced Cr and Co content.

Metallurgical Synthesis of Twinning Induced Non-Equiatomic High Entropy Alloys

The non-equiatomic Fe40Mn40Co10Cr10 alloy was melted in a vacuum induction furnace from metals with purities above 99.8 wt.% and cast into a water-cooled copper mold and allowed for

furnace-cooling. Then the material was hot rolled at 900 °C to 50% thickness reduction, followed by

homogenization at 1200 °C for 2 h in Ar atmosphere and quenched in water.

The crystal structure of the alloy was analyzed using various techniques. X-ray diffraction measurements (Huber-2 goniometer) were conducted using Co ja radiation (k = 1.79 A). Secondary

electron (SE) imaging and electron backscatter diffraction (EBSD) were conducted in a 6500F JEOL field emission gun-scanning electron microscopy (FEG-SEM) equipped with an EDAX software and a

TSL OIM EBSD system.

Why should we relax the equiatomic composition rule in the design of High Entropy Alloys ?

1)

The high entropy design rules can be modified to additionally consider interstitial alloying elements, specifically solute C. Interstitial elements, specifically C and N, offer very interesting

alloying options with respect to stabilizing fcc solid solutions as is also expressed by their effect on the VEC. Similar aspects apply to B and even H (yes, as an alloy element). Equiatomic

fractions of C, N or B lead to carbides, nitrides and borides, hence, the equiatomic composition rule makes not so much sense as the main aim and art lies in solid solutiun blending.

2)

A second design idea, deviating from the classical multi-component concept, lies in using relatively lean and non-equiatomically portioned compositions. This is due to the fact that in many

transition metal alloy solid solutions the shape of the configurational entropy as a function of chemical composition assumes a relatively flat and compositionally wide plateau. This means that the

entropy curve has a weak maximum and no steep changes, except for the case of very small concentrations. This fact suggests that entropy-based stabilization of massive solid solutions can also

be achieved for non-equiatomic quinary and quaternary alloy compositions.

This modifies the original high entropy alloying concept, where none of the alloying elements was meant to dominate, into a class of e.g. Fe-based or Ni-based or Ti- based materials.

3)

Beyond the argument associated with the flat entropy curve there are other good reasons for designing compositionally simplified high entropy alloys:

An obvious motive lies in reducing alloying costs. Any material that is being designed and meant to be used for specific applications must pass the critical test whether the respective alloying

elements and their quantities are indeed required to reach a design target or not. If not, their respective alloying content can be reduced. Examples are typical bounds known for

established commercial alloys such as a certain Cr and Mo content in stainless steels for achieving sufficient pitting and corrosion resistance; specific values of Ni and Al in superalloys required

to arrive at the characteristic matrix – precipitate structure; a certain Cu content for precipitating Guinier-Preston zones in age hardening aluminum alloys; or a minimum required Nb or Ta content

to stabilize elastically compliant bcc Ti alloys.

In all these metallurgical examples the respective alloying elements are only added to the content that is required for achieving the aims described, but the alloying content is not increased beyond

these values if not serving a specific thermodynamic, kinetic or property function. However, in cases where a near-maximum value of the configurational entropy can be realized at smaller

alloying content, i.e. before reaching an equiatomic composition, no need exists to alloy further. In other words the presence of a long and flat compositional entropy plateau enables to exploit a

wider mixing range and less consumption of expensive alloying ingredients when designing high entropy alloys.

4)

Another issue in realizing homogeneous massive crystalline solid solutions is not the maximization of the entropy but rather the avoidance of intermetallic phases. When aiming at stabilizing a

single phase compositionally complex material it is from a thermodynamic standpoint more plausible to analyze the likelihood of intermetallic compounds in the multicomponent phase diagram rather than

only analyzing the configurational entropy.

It was recently observed that the entropy-maximized 25% equiatomic quaternary FeMnCoCr alloy (being close to the well-known Cantor alloy) surprisingly leads to a complex multiphase microstructure

containing several intermetallic phases while the non-equiatomic material Fe40Mn10Co10Cr produces a homogeneous fcc single phase. This shows that a high entropy contribution to the stabilization of

the matrix alone is often not sufficient to over-compensate enthalpy advantages of competing intermetallic phases. This might be also the reason why truly single phase high entropy phases have been

realized only for a few compositions so far. Introducing a non-equiatomic mixing rule would provide a much larger compositional space for synthesizing high entropy alloys without intermetallic

phases.

5)

Another set of advantages associated with lean multi-component compositions is a practical one, such as reducing variations in vapor pressure typically occurring in multi-component systems, less

segregation and improved casting properties.

6)

A further aspect that should be realized is that XRD, EBSD and atom probe tomography analysis increasingly reveals that many of the high entropy alloys that have been studied so far are actually not

single phase materials but often contain intermetallic phases. A well investigated exception from this is the multi-component yet single phase fcc Cantor alloy FeMnNiCoCr.

The occurrence of one or often more intermetallic phases, sometimes with nanoscopic size or at grain boundaries, is not only a thermodynamic or kinetic issue. The presence of intermetallic phases

typically deteriorates mechanical key properties such as ductility, fatigue resistance and toughness. Alloys containing intermetallic phases, therefore, often reveal inferior properties compared to

corresponding single-phase alloys of similar, yet non- equiatomic composition.

An additional point supporting non-equiatomic multi-component alloys in the form of high entropy steels is to better exploit fcc phase stabilization and strain hardening effects associated with

interstitial elements, specifically C which has been well studied in the context of TWIP steel systems.

7)

Another recently observed effect is that strain hardening in HEAs can come from cluster formation (and not from maximized solid solution), hence, also suggesting to relax the

equiatomic composition rule.

8)

For improved strain hardening such as TWIP and TRIP it makes more sense to optimize alloy composition for a specific range of the stacking fault energy and not for maximum entropy. The discovery of

several very strong and ductile TWIP and TRIP HEAs underpin this argument.

What is the cyclic stress-strain response of dual-phase high-entropy alloys?

The recently developed dual-phase high-entropy alloys are characterized by pronounced strain hardening and high ductility under monotonic loading owing to the associated transformation induced plasticity effect. Fatigue properties of high-entropy alloys have not been studied in depth so far. Our current study focuses on the low-cycle fatigue regime. Cyclic tests were conducted and the microstructure evolution was studied post-mortem. Despite deformation-induced martensitic transformation during cycling at given plastic strain amplitudes, intense strain hardening in the cyclic stress-strain response is not observed. This behavior is attributed to the planar nature of slip and partial reversibility of deformation.

Scripta Materialia 143 (2018) 63–67

High Entropy Alloy fatigue Response.pdf

PDF-Dokument [1.5 MB]

Combinatorial metallurgical design of high entropy alloys and non-equiatomic high entropy alloys

In this project, we use a combinatorial metallurgical synthesis approach, referred to as Rapid Alloy Prototyping, for the rapid compositional and mechanism oriented trend screening of metallurgically melted non-equiatomic CoCrFeMnNi and CoCrFeMn alloys.

The produced alloy compositions span over wide ranges for both systems: Fe(64x)Mnx-Ni27.7±1.3Co5.6±0.3Cr2.3±0.1 (x = 21/24/27/34/38) and

Fe(80y)MnyCo10±1Cr10±1 (y = 31/35/42, 45) (at.% throughout). These two systems were selected as they enable the investigation of the influence

of several parameters (e.g., configurational entropy, Ni content, and stacking fault energy) on the overall properties. To this end, it is of specific importance to assess the limits

of single solid solution formability.

In fact, the latter system allows investigating the transition from a single phase to a multiphase microstructure. In the current project, however, the focus is placed on one

non-equiatomic alloy from each alloy class, i.e., Fe40Mn27Ni26Co5Cr2

and Fe37Mn45Co9Cr9, respectively, demonstrating the selected overall characteristics of these two systems.

The proposal of configurational entropy maximization to produce massive solid-solution (SS)-strengthened, single-phase high-entropy alloy (HEA) systems has gained much scientific interest. Although most of this interest focuses on the basic role of configurational entropy in SS formability, setting future research directions also requires the overall property benefits of massive SS strengthening to be carefully investigated. To this end, taking the most promising CoCrFeMnNi HEA system as the starting point, we investigate SS formability, deformation mechanisms, and the achievable mechanical property ranges of different compositions and microstructural states.

High entropy alloys JOM 2014 Tasan et al[...]

PDF-Dokument [2.4 MB]

The role of the valence electron concentration fopr the design of new high entropy alloys

The empirically observed relevance of the valence electron concentration (VEC) for solid solutions has led to a corresponding design guideline, suggesting VEC < 6.87 for stable

body-centered cubic (bcc) and VEC > 8 for stable face-centered cubic (fcc) phases.

It should be considered in that context that different definitions for the valence electron concentration calculations exist in the literature. Sometimes also different valence numbers are used

specifically for some of the transition metals with d electrons.

Interestingly, these features do not only apply to High Entropy Alloys.

Many highly alloyed steels which can thus be considered as non-equiatomic Fe–Mn-based high-entropy steels have a VEC of 7–8 when only counting the substitutional elements. However, when

additionally counting the electrons provided by interstitial elements such as C and N, the high-entropy steels presented here reach even higher VECs. This observation suggests that for

synthesizing high entropy alloys with a stable fcc matrix, alloying and the associated electron donation provided by interstitial elements could become an interesting new design

variant.

What are High-Entropy Steels?

Massively alloyed multi-component alloys which are also referred to as high-entropy alloys represent a class of metallic materials containing typically five or more principal alloying elements in equiatomic or near equiatomic proportions. While early efforts in this direction were inspired from recipe guidelines devised originally for metallic glasses, the current work in this field aims at designing crystalline entropy-stabilized massive solid solution phases of equiatomic composition.

These original high-entropy or respectively multi-component alloy concepts outlined above serve as a starting point for designing compositionally complex yet non-equiatomically proportioned

Fe-based, viz. steel related materials.

The high-entropy design rules also apply to some extent for certain steel type alloys, however, we additionally consider interstitial alloying elements, specifically solute C, N and

B.

One should emphasize this point since corresponding massive solid solution effects associated with interstitial elements have not yet been considered in multicomponent transition metal alloys.

Interstitial elements, specifically C and N, offer very interesting alloying options with respect to stabilizing fcc solid solutions as is also expressed by their effect on the VEC.

A second design idea, deviating from the classical multi-component concept, lies in using relatively lean and non-equiatomically portioned compositions. This is due to the fact that in many

transition metal alloy solid solutions, the shape of the configurational entropy as a function of chemical composition assumes a relatively flat and compositionally wide plateau. This means

that the entropy curve has a weak maximum and no steep changes, except for the case of very small concentrations.

This fact suggests that entropy-based stabilization of massive solid solutions can also be achieved for non-equiatomic quinary and quaternary alloy compositions.

This modifies the original high entropy alloying concept, where none of the alloying elements were meant to dominate, into a class of Fe-based materials which we consequently refer here to as

high-entropy steels.

Beyond the argument associated with the flat entropy curve, there are other good reasons for designing compositionally simplified high-entropy alloys: An obvious motive lies in reducing alloying

costs. Any material that is being designed and meant to be used for specific applications must pass the critical test whether the respective alloying elements and their quantities are indeed

required to reach a certain design target or not. If not, their respective alloying content can be reduced.

Examples are typical bounds known for established commercial alloys such as a certain Cr and Mo content in stainless steels for achieving sufficient pitting and corrosion resistance; specific

values of Ni and Al in superalloys required to arrive at the characteristic matrix—precipitate structure; a certain Cu content for precipitating Guinier–Preston zones in age hardening

aluminum alloys; or a minimum required Nb or Ta content to stabilize elastically compliant bcc Ti alloys.

In all these metallurgical examples, the respective alloying elements are only added to the content that is required for achieving the aims described, but the alloying content is not increased

beyond these values if not serving a specific thermodynamic, kinetic, or property function. However, in cases where a near-maximum value of the configurational entropy can be realized at

smaller alloying content, i.e., before reaching an equiatomic composition, no need exists to alloy further. In other words, the presence of a long and flat compositional entropy plateau enables

to exploit a wider mixing range and less consumption of expensive alloying ingredients when designing high entropy alloys.

Another issue in realizing homogeneous massive crystalline solid solutions is not the maximization of the entropy but rather the avoidance of intermetallic phases. When aiming at stabilizing a

single-phase compositionally complex material, it is from a thermodynamic standpoint more plausible to analyze the likelihood of intermetallic compounds in the multi-component phase diagram

rather than only analyzing the configurational entropy.

Inspired by high-entropy alloys, we study the design of steels that are based on high

configurational entropy for stabilizing a single-phase solid solution matrix. The focus is

placed on the system Fe–Mn–Al–Si–C but we also present trends in the alloy system

Fe–Mn–Al–C. Unlike in conventional high-entropy alloys, where five or more equiatomically proportioned components are used, we exploit the flat configurational entropy plateau in transition metal mixtures, stabilizing solid solutions also for lean, non–equiatomic compositions. This renders the high-entropy alloying concept, where none of the elements prevails, into a class of Fe-based materials which we refer to as high-entropy steels.

Raabe_et_al-2015-steel_research_internat[...]

PDF-Dokument [1.8 MB]

![A twinning-induced plasticity (TWIP) high entropy alloy. Deformation twins at 45% true strain in Fe40Mn40Co10Cr10 revealed by TEM: (a) dark field micrograph with beam direction [002]T; (b) selected-area diffraction pattern; (c) orientation and phase mapping](https://www.dierk-raabe.com/s/cc_images/cache_2489131658.jpg?t=1603558755)