Crystallographic Textures of Steels

Why are crystallographic textures important ?

Many important materials, such as metallic alloys, engineering and function ceramics, many biological materials and also some polamyers assume a polycrystalline structure.

Since the individual properties of the overall polycrystalline material depend on those of the constituent single crystals then also most directionally dependent (tensorial) parameters characterizing

the polycrystalline state depends on the overall distribution of the orientation distribution (texture) of these crystals.

Certain properties such as fracture toughness, electrical conductivity, diffusion, superconductivity, crystal plasticity, mechanical twinning etc of the crystals can be very strongly directionally

dependent, hence the crystallographic orientation distribution of the crystallites within the polycrystalline aggregate, referred to as crystallographic texture, plays an important role among these

parameters. When all possible orientations of the crystallites occur with equal frequency, the orientation dependence may disappear on the average.

This means that in such specific cases the entire polycrystal may appear as an isotropic material. However, the occurrence of polycrystalline materials with entirely random orientation distributions is a very rare exception. Instead most materials inherit very strong crystallographic textures due to specific underlying mechanisms related to nucleation, growth, crystal plasticity and recrystallization as well as grain growth. Most of these mechanisms are crystallographic dependent and hence lead to strong crystallographic textures as a result of synthesis and processing.

Crystallographic texture and sheet forming operations

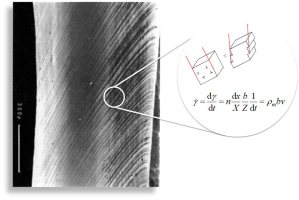

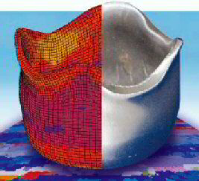

Engineering polycrystalline sheet steels often exhibit significant elastic-plastic anisotropy at the single crystal level that can be attributed to the presence of crystallographic textures.

In the early industrial practice such crystallographic textures were long seen as a property of polycrystals which was inherited from the preceding processing steps without conducting particular anisotropy optimization. This means that textures were originally accepted as an inevitable side-effect of materials processing which was hard to avoid and hece it was often accepted as it was.

In contrast, modern industrial process design aims at optimizing microstructures and properties during production, i.e. its goal consists in exploiting metallurgical mechanisms such as crystal plasticity, recrystallization, grain growth, and phase transformation for the design of well tailored crystallographic textures with respect to certain desired anisotropy properties of the final product.

How can crystallographic textures of steels be grouped ?

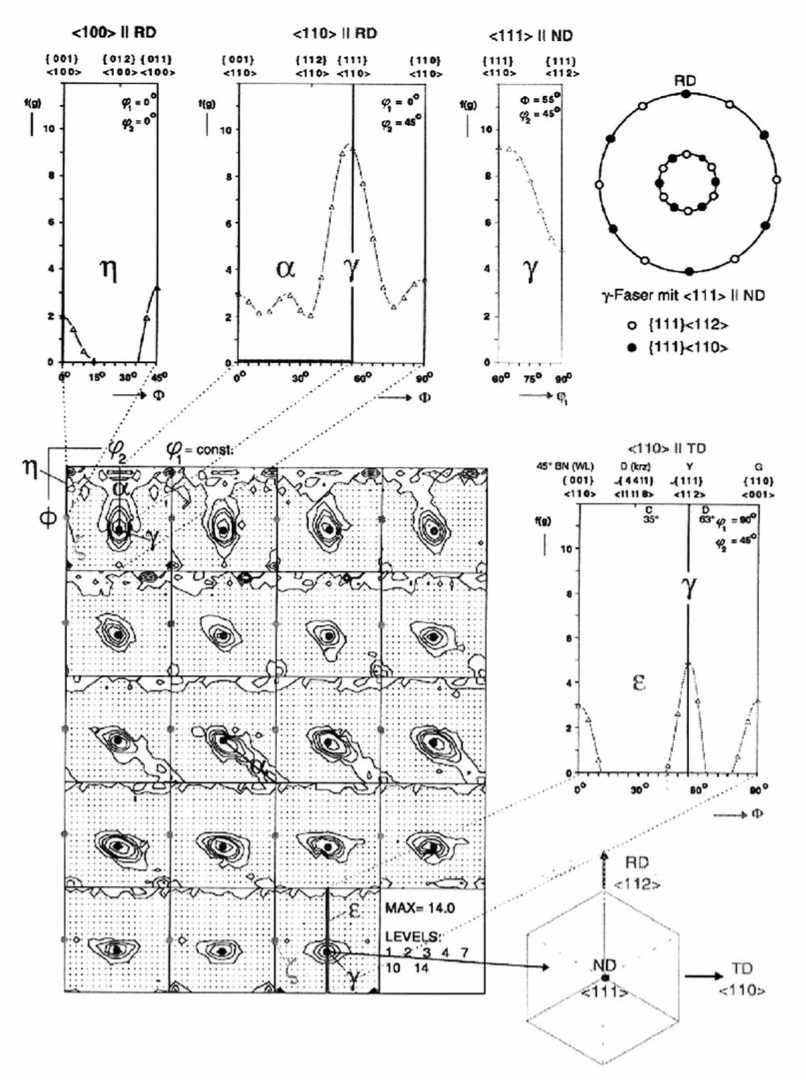

The rolling and recrystallization textures of the different types of bcc steels often show great similarities, but also exhibit characteristic differences which, e.g. depend upon starting texture, microstructure and condition of precipitations. In this paper this behaviour will be discussed for three examples belonging to three entirely different types of steels.

More specific, the rolling and recrystallization texture development of bcc steels is discussed for three examples belonging to three different types of steels, namely deep drawing steels (e.g. low carbon steel), ferritic stainless steels (e.g. Fe16%Cr) and electrical steels (e.g. Fe3%Si).

steel research 62 (1991) No. 12, page 567

Overview textures steels.pdf

PDF-Dokument [1.2 MB]

Crystallographic textures of soft deep drawing FeC steels

Deep-drawing steels (e.g, low-carbon steel): Here the most important property is a good deformability in deep drawing. This behaviour is favoured by a texture formed in such a way that during deep drawing the material flow occurs from the width and not from the thickness of the sheet and that it is equal for different directions in the sheet plane, i.e. by materials with the high r-value and a low Delta- r value (r is the Lankfort parameter). Both properties can be achieved by a texture which after recrystallization consists of a homogeneous strong fibre texture with a {111} plane parallel to the sheet plane.

Crystallographic textures of ferritic stainless FeCr steels

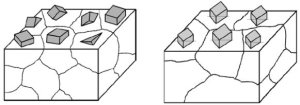

Ferritic stainless steels (e.g. Fe16%Cr): Here again the requirements for deep drawability should be fulfilled, but additionally the ridging which often occurs in Cr-steels should be suppressed. This again means a {111} fibre texture but also a topologically random arrangement of crystallites should be achieved).

Materials Science and Technology 9 (1993) 302-312.

Raabe Mater Science Techn Ferritic Stain[...]

PDF-Dokument [2.0 MB]

Crystallographic textures and roping / ridging in ferritic stainless steels

The macrotextures and microtextures of the ferritic stainless steel hot band material has a very strong influence on the further evolution of the snsuing textures formed during the downstream cold rolling and recrystallizaton of the ferritic stainless steel sheets. Any modification of the initial inerited hot band texture and microstructure for instance by means of 45° ND cross-rolling led to an improvement of the macro and micro-textures in the finally recrystallized sheets. These modifications entailed an enhanced planar anisotropy and less severe ridging. The correlation of local riding profiles taken from tensile specimens with half thickness and corresponding EBSD orientation maps reveal that elongated orientation colonies formed close to the sheet center are responsible for ridging in cold rolled and recrystallized ferritic stainless steel sheet.

steel research int. 76 (2005) No. 11 page 797

stainless-steel-steel research int. 76 ([...]

PDF-Dokument [5.5 MB]

Crystallographic textures of electrical soft magnetic FeSi steels

Electrical steels (e.g, Fe3%Si transformer steels): For the use of these steels in transformers high magnetic permeability for magnetization in rolling direction is required which can be obtained by a <100> direction parallel to the rolling direction. Technologically this can be achieved by forming a very sharp Goss texture {011}<100> by secondary recrystallization.

Which types of hot rolling textures of steels exist?

The crystallographic textures of hot rolled steels can be classified into three fundamental groups of textures. The first group comprise pure Fe, some weakly bonded B2 and DO3 structured

intermetaues and closely related alloys such as ferritic low carbon and microalloyed interstitial free steels. The second group

includes highly alloyed corrosion-resistant ferritic stainless steels and Fe-Si transformer steels (also referred to as electrical steels). Typcial examples are steels with 11-20 wt.% Cr and / or

with up to 3.4 wt.% Si as well as body centered cubic transition metals such as Ta, Mo, V, W, Mo and Nb which do not undergo any phase transformation during hot rolling. The third group comprises

stable and instable austenitic stainless steels for instance on the basis of higher amounts Cr and Ni or Mn as well as duplex steels.

steel research vol 74 (2003) NO. 5, page 327

steel research vol 74 2003 overview roll[...]

PDF-Dokument [2.6 MB]

steel research 66 (1995) NO.5 page 222

Raabe steel research vol 66 (1995) 222 s[...]

PDF-Dokument [1.3 MB]