3D Printing of Metals: Laser Additive Manufacturing (LAM) via Selective Laser Melting (SLM) and Laser Metal Deposition (LMD)

Additive Manufacturing (AM) is a revolutinary metallurgical production method capable of producing highly complex parts directly from a computer file and raw material.

Its high potential lies in its ability to manufacture customised products with individualisation, complexity and weight reduction for free.

For metallurgical 3D priniting the Laser-assisted Additive Manufacturing (LAM) methods prevail.

Advantages of Additive Manufacturing for metals: Geometry

The advantage of the additive manufacturing method, which allows almost unlimited object geometries to be produced, means that complex internal structures - e.g. cooling channels with a free-form three-dimensional shape - and undercuts can also be created, which is why corresponding processes are used today in toolmaking and medical technology. The comparatively few boundary conditions to be met in terms of design with this technology relate in particular to the avoidance of internal inclusions, the maintenance of sufficient wall thicknesses and the consideration of surface quality.

Advantages of Additive Manufacturing for metals: Filigree Design

The filigree structures that can be produced efficiently with additive manufacturing processes are particularly suitable for lightweight construction, which is why such processes are playing an increasingly important role in the aerospace industry and in the production of engines and turbomachinery.

Advantages of Additive Manufacturing for metals: Indvidualized Design

In many industries, a trend towards product individualization can now be observed. For production, this means a greater variety of variants with simultaneously decreasing numbers of units within a single production series, which is why the economic advantages of mass production (economies of scale) are not being realized with regard to these production technologies; customer-specific product requirements can therefore hardly be implemented in an economic form. Highly individualized mass goods therefore require manufacturing processes that are cost-effective and close to the final contour, i.e. without expensive post-processing steps. Additive manufacturing fulfils such criteria and enables individual or small series production with almost unlimited creative freedom.

Advantages of Additive Manufacturing for metals: Time advantage

The elimination of tools and the completely digitalized process chain up to the actual product manufacture mean that in additive manufacturing, the time from the design of an object on the computer to its completion is significantly shorter than in conventional processes. The high integrated production and manufacturing speed means that additive manufacturing processes have been used in prototype construction ("rapid prototyping") for some time; for example, it enables the rapid provision of spare parts, possibly combined with decentralized production. This makes additive manufacturing devices, so-called 3D printers, interesting for private users as well, since individual, possibly complex parts can be produced according to individual needs without having to rely on lengthy manufacturing processes consisting of many individual steps.

Two main methods are used in the field of Laser Additive Manufacturing:

Laser Additive Manufacturing (LAM):

Selective Laser Melting (SLM) & Laser Metal Deposition

Laser Additive Manufacturing is a technique that enables producing complex parts and products directly on the basis of a digital computer model file and raw material powders. Its extremely high potential for manufacturing and metallurgy lies in its unique ability to manufacture customised products with individualisation, complexity and weight reduction for free. Up to now, this potential cannot be fully realised because no materials tailor-made for these unique processes exist. Our interest lies in merging expertise on the process design side with advanced materials design and characterization to develop novel tailor-made materials suitable for and exploiting the unique characteristics of Laser Additive Manufacturing, together with their respective optimized manufacturing technology. As a result, new materials will be available for the field of Laser Additive Manufacturing that can be processed without costly post treatments and that exceed the properties of their conventional counterparts. At the same time, Laser Additive Manufacturing enables a new and accelerated approach to rapid alloy design.

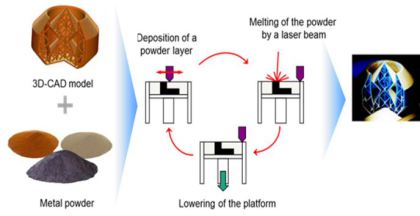

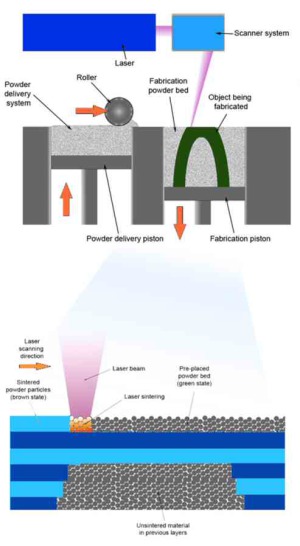

Selective Laser Melting (SLM) uses a laser to melt powdered metal in chamber of inert gas or vacuum.

When a layer is finished, the powder bed is moved downward, and an automated roller adds a new metal poweder layer which is melted to form the next cross section of the

model.

SLM is a metal additive manufacturing technique similar to Selective Laser Sintering (SLS).

A main difference between them being that SLS sinters the material, i.e heating to below the melting point until the particles merge with one another, while SLM melts the material, creating

a melt pool in which material is consolidated before cooling to form a solid structure.

Also, in SLM each new layer synthesis leads to a heat treatment of the already solidified layer beneath it.

Why is additive manufacturing of interest?

Additive manufacturing allows objects to be created in almost any three-dimensional shape. In such a manufacturing process, a wide variety of materials can be processed. The spectrum ranges from

plastics through metals and organic fabrics to ceramics. The production of an object takes place by repeated application of the material used according to a previously defined computer-aided object

description.

Additive manufacturing therefore offers a comparatively simple way of producing objects with a filigree inner structure or complex shape. In addition, additive technologies make it possible to tailor

individualized, customer-specific products quickly and cost-efficiently without great effort and expense.

Due to such advantages, additive manufacturing has already become firmly established in many different fields of application, such as toolmaking, medical technology or aerospace. Nevertheless, the

new technology is only at the beginning of its possibilities. Numerous processes, processes and materials for further fields of application are currently still under development, but are likely to

change the culture of industrial production profoundly and sustainably in the future.

What are the individual process steps in additive manufacturing?

i) Structure of the digital object description. First, a digital model is created that meets all the requirements of the end product (eg material properties, weight, stability, surface finish). Subsequently, the digital model is transferred to an exchange data format.

ii) Planning and computer-aided simulation of the additive manufacturing process. Location and orientation of the object to be manufactured within the workspace are defined. In

addition, the manufacturing strategy is defined (energy input, type of material order, support structures, etc.).

iii) Additive object fabrication and post-processing. The object is produced according to the planning defined in the digital model. Depending on the material, different

manufacturing processes are used (eg powder bed melting, strand-laying processes or binder printing). Subsequent to the manufacturing process, the post-processing (eg removal of the support

structures, post-processing or coating of the surfaces) takes place.

iv) examination of the quality of the object. Due to the individualized production, the comprehensibility and control of the additive production is of great importance, as well as

the documentation of the achieved object quality. The quality of an additive manufactured product depends strongly on the course of the manufacturing process. Quality control includes, for example,

compliance with geometric accuracy, ensuring functionality and ensuring surface quality.

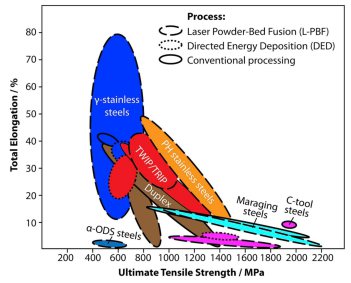

Steels in additive manufacturing: processing, microstructures and properties

A large number of different steels are being processed by Additive Manufacturing (AM) methods. The different microstructure features and phases (austenite, ferrite, martensite) and the various precipitation phases (intermetallic precipitates, carbides) leverage a wide variability in microstructure and properties. This is true for AM-produced steels just as it is for conventionally-produced steels. However, steels are subjected during AM processing to time-temperature profiles which are very different from the ones encountered in conventional process routes, and hence the resulting microstructures differ strongly as well. This includes a very fine and highly morphologically and crystallographically textured microstructure as a result of high solidification rates as well as non-equilibrium phases in the as-processed state. Such a microstructure, in turn, necessitates additional or adapted post-AM heat treatments and alloy design adjustments. In this review, we give an overview over the different kinds of steels in use in fusion-based AM processes and present their microstructures, their mechanical and corrosion properties, their heat treatments and their intended applications. This includes austenitic, duplex, martensitic and precipitation-hardening stainless steels, TRIP/TWIP steels, maraging and carbon-bearing tool steels and ODS steels. We identify areas with missing information in the literature and assess which properties of AM steels exceed those of conventionally-produced ones, or, conversely, which properties fall behind. We close our review with a short summary of iron-base alloys with functional properties and their application perspectives in Additive Manufacturing.

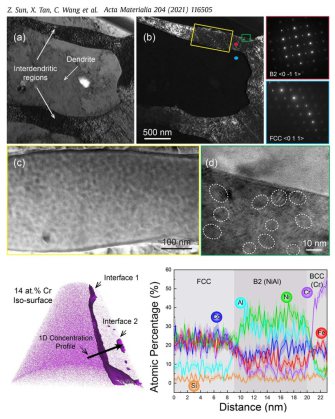

Additive manufacturing of a high-entropy alloy

One major hindrance that alloy design for additive manufacturing (AM) faces nowadays is hot tearing. Contrary to the previous works which either try to reduce solidification range or introduce

grain refinement, the current work presents a new approach of employing segregation engineering to alter the

residual stress states at the interdendritic and grain boundary regions and consequently prevent hot tearing. Here, in situ Al alloying is introduced into an existing hot-cracking susceptible

high-entropy alloy CoCrFeNi. It is found that within a certain range of compositions, such as Al 0.5 CoCrFeNi, the hot crack

density was drastically decreased.

Acta Materialia 204 (2021) 116505

Acta Mater 2020 hot tearing grain bounda[...]

PDF-Dokument [5.9 MB]

An application case for aerospace parts: Selective laser melting of Ti-6Al-4V

Microstructure, phase composition and intrinsic heat treament during building during selective laser melting (SLM) of Ti-6Al-4V play important roles for the parts's final mechanical performance.

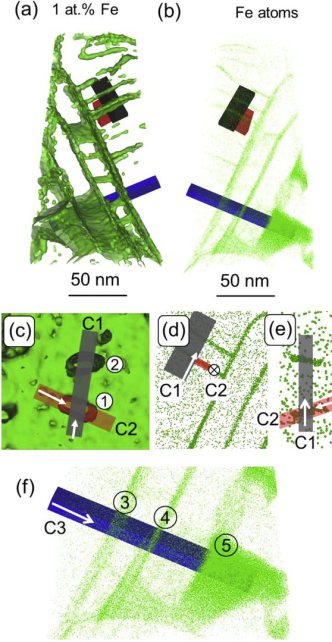

In this project we studied the microstructure evolution in SLM Ti-6Al-4V in the as-built condition and after sub-transus heat treatments between 400°C and 800°C focusing on

elemental partitioning and the role of lattice defects on precipitation of the BCC beta phase. With SLM parameters corresponding to low volume energy density the as-built microstructure

consisted of acicular martensite and showed a higher density of lattice defects than that synthesized under high energy building conditions. High energy X-ray synchrotron diffraction indicated

the presence of ~2 wt.% beta phase. Moreover, atom-probe tomography revealed enrichments in beta-stabilizers at one and two-dimensional lattice defects. These fine enriched one-dimensional

columnar and planar features are identified as precursors of the beta-phase, revealing the role of lattice defects for beta precipitation. Upon annealing at 400°C and 530°C, the thin beta-films

began to fragment into beta platelets and nanoparticles, whereas annealing at 800°C led to a coarse-lamellar alpha/beta-microstructure. Moreover, a2- Ti3Al was found in the 400°C annealed

condition. In line with the microstructure changes, Vickers hardness increased upon annealing at temperatures up to 530°C and dropped when coarsening occurred at higher temperatures.

Substantial element partitioning occurred during thermally driven martensite

decomposition, which was significantly stronger for Fe than for V.

Acta Materialia 167 (2019) 136-148

AMT64 Acta 2019 lattice defects partitio[...]

PDF-Dokument [4.2 MB]

Additive manufacturing of non-weldable nickel-base superalloys

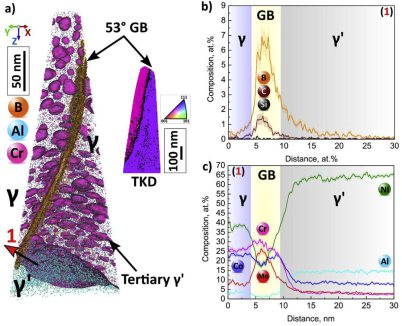

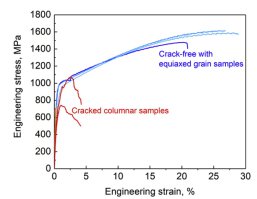

The mechanisms that lead to hot cracking in parts build by additive manufacturing (AM) of non-weldable nickel-based superalloys are still unclear. We thus run several projects to obtain better

understanding of the root causes of hot cracking which is an impediment to designing engineering parts for safety-critical applications.In these projects we deploy a near-atomic-scale approach to

investigate the details of the compositional decoration of grain boundaries in the coarse-grained, columnar microstructure in parts built from a non-weldable nickel-based superalloy by selective

electron-beam melting. The progressive enrichment in Cr, Mo and B at grain boundaries over the course of the AM-typical successive solidification and remelting events, accompanied by solid-state

diffusion, causes grain boundary segregation induced liquation. This

observation is consistent with thermodynamic calculations. We demonstrate that by adjusting build parameters to obtain a fine-grained equiaxed or a columnar microstructure with grain width

smaller than 100 mm enables to avoid cracking, despite strong grain boundary segregation. We find that the spread of critical solutes to a higher total interfacial area, combined with lower

thermal stresses, helps to suppress interfacial liquation.

Acta Materialia 177 (2019) 209

Acta Mater 2019 Atomic-scale grain bound[...]

PDF-Dokument [5.9 MB]

Synthesis and stabilization of a new phase regime in a Mo-Si-B based alloy by laser-based additive manufacturing

Mo-Si-B alloys are potential creep resistant materials for accessing harsh loading scenarios beyond Ni-based superalloys due to their excellent mechanical performance at ultra-high

temperatures (>1200°C). Here, we report on the fabrication through laser additive manufacturing of a Mo rich Mo-Si-B alloy with and without dispersion of oxide (La2O3) particles. The major

phase in the solidified material is dendritic a-Mo. The inter-dendritic regions contain a mixture of the Mo5Si3 (T1) þ Mo5SiB2 (T2) phases, and not the expected equilibrium Mo3Si þ Mo5SiB2

(T2) phases. This combination of phases is shown to

yield improved high temperature creep resistance but was only accessible through by addition of Nb, W or Ti that substitute Mo in the intermetallic phases. Whereas here it is attributed to the

large undercooling in the small melt pool produced during laser processing. We show that this phase mixture, upon

annealing, is stable at 1200°C for 200 h. We also demonstrate successful dispersion of oxide particles mainly in the inter-dendritic regions leading to a high indentation fracture toughness of

~18 MPa√m at room temperature. Toughening originates from crack trapping in the ductile a-Mo and the formation of micro-cracks and crack deflection in the vicinity of oxide particles.

Acta Materialia 151 (2018) 31

Makineni Mo-Si-B additive manufacturing [...]

PDF-Dokument [2.6 MB]

Overview of steels in additive manufacturing

A high number of steels has been processed by Additive Manufacturing (AM) methods. The different microstructure components and phases (austenite, ferrite, martensite) and the various

precipitate phases (intermetallic precipitates, carbides) convey a huge variability in microstructure and properties to this

class of alloys. This is true for AM-produced steels just as it is for conventionally-produced steels. However, steels are subjected during AM processing to time-temperature profiles which are

very different from the ones encountered in conventional process routes, and hence the resulting microstructures differ strongly as well. This includes a very fine and highly

morphologically and crystallographically textured microstructure as a result of high solidification rates as well as non-equilibrium phases in the as-processed state. Such a microstructure,

in turn, necessitates additional or adapted post-AM heat treatments and alloy design adjustments. This review provides an overview over the different kinds of steels in use in fusion-based AM

processes and present their microstructures, their mechanical and corrosion properties, their heat treatments and their intended applications. This includes austenitic, duplex, martensitic and

precipitation-hardening stainless steels, TRIP/TWIP steels,

maraging and carbon-bearing tool steels and ODS steels.

Laser additive manufacturing production of oxide- and nitride-dispersion-strengthened materials through atmospheric reactions in liquid metal deposition

Despite being extremely attractive compounds for strengthening, oxides and nitride particles have found only limited use in metallic materials design, as obtaining appropriate size and

dispersion up to nownecessitates production

by time- and cost-intensive powder metallurgy processes. Here we present an alternative production method, based on the oxide and nitride formation during liquid-metal-deposition procedures in

oxygen and/or nitrogen containing atmospheres. Rapid solidification of the small liquid zone suppresses floatation and agglomeration of particles, while subsequent thermo-mechanical

treatments densify the material and aids particle dispersion. The in-situ particle formation coupled to the high deposition rates ensures a drastically shortened production chain. The

feasibility of the method is exemplarily demonstrated on austenitic stainless steel and commercially available deposition techniques as used in additive manufacturing, performed without

shielding gas but instead at air. Evenwithout substantial optimisation of processes and material, N2 vol.% of hard and stable Cr2N particles with sizes down to 80 nm could be evenly

dispersed, resulting in pronounced strengthening at both roomtemperature and 700°C without significant loss in ductility.

Materials and Design 111 (2016) 60-69

Materials and Design 111 (2016) 60 Addit[...]

PDF-Dokument [4.0 MB]

Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting

Materials produced by selective laser melting (SLM) experience a thermal history that is markedly different from that encountered by conventionally produced materials. In particular, a very high cooling rate from the melt is combined with cyclical reheating upon deposition of subsequent layers.

Using atom-probe tomography (APT), we investigated how this conventional thermal history influences the phase-transformation behavior of maraging steels

(Fe–18Ni–9Co–3.4Mo–1.2Ti) produced by SLM. We found that despite the “intrinsic heat treatment” and the known propensity of maraging steels for rapid clustering and precipitation, the

material does not show any sign of phase

transformation in the as-produced state. Upon aging, three different types of precipitates, namely (Fe,Ni,Co)3(Ti,Mo), (Fe,Ni,Co)3(Mo,Ti), and (Fe,Ni,Co)7Mo6 (l phase), were observed as well

as martensite-to-austenite reversion around regions of the retained austenite. The concentration of the

newly formed phases as quantified by APT closely matches thermodynamic equilibrium calculations.

Jägle et al. (2014) 29 17 Laser additive[...]

PDF-Dokument [489.4 KB]

Comparison of Maraging Steel Micro- and Nanostructure Produced Conventionally and by Laser Additive Manufacturing

Maraging steels are used to produce tools by Additive Manufacturing (AM) methods such as Laser Metal Deposition (LMD) and Selective Laser Melting (SLM). Although it is well established that dense

parts can be produced by AM, the influence of the AM process on the microstructure - in particular the content of retained and reversed austenite as well as the nanostructure, especially the

precipitate density and chemistry, are not yet explored. In this specific project, we study these features using microhardness measurements, Optical Microscopy, Electron Backscatter Diffraction

(EBSD), Energy Dispersive Spectroscopy (EDS), and Atom Probe Tomography (APT) in the as-produced state and during ageing heat treatment. We find that due to microsegregation, retained austenite

exists in the as-LMD- and as-SLM-produced states but not in the conventionally-produced material. The hardness in the as-LMD-produced state is higher than in the conventionally and SLM-produced

materials, however, not in the uppermost layers. By APT, it is confirmed that this is due to early stages of precipitation induced by the cyclic re-heating upon further deposition—i.e., the

intrinsic

heat treatment associated with LMD. In the peak-aged state, which is reached after a similar time in all materials, the hardness of SLM- and LMD-produced material is slightly lower than in

conventionally-produced material due to the presence of retained austenite and reversed austenite formed during ageing.

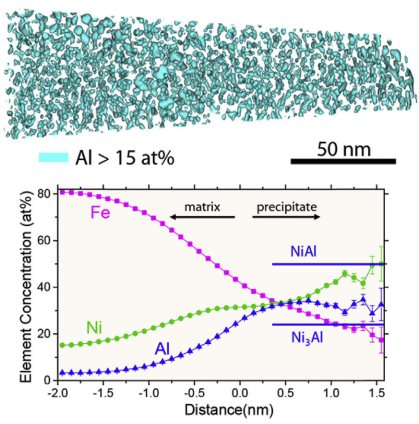

Exterme nanoprecipitation in an Fe-19Ni-xAl maraging steel by intrinsic heat treatment during laser metal deposition

Due to the layer-by-layer build-up of additively manufactured parts, the deposited material experiences a cyclic re-heating in the form of a sequence of temperature pulses. In the current

work, this “intrinsic heat treatment (IHT)” was exploited to induce the precipitation of NiAl nanoparticles in an Fe-19Ni-xAl (at%)

model maraging steel, a system known for rapid clustering. We used Laser Metal Deposition (LMD) to synthesize compositionally graded specimens. This allowed for the efficient screening of

effects associated with varying Al contents ranging from 0 to 25 at% and for identifying promising concentrations for further studies. Based on the existence of the desired martensitic

matrix, an upper bound for the Al concentration of 15 at% was defined. Owing to the presence of NiAl precipitates as observed by Atom Probe Tomography (APT), a lower bound of 3e5 at% Al was

established. Within this concentration window, increasing the Al concentration gave rise to an increase in hardness by 225 HV due to an exceptionally high number density of 1025 NiAl

precipitates per m3, as measured by APT. This work demonstrates the possibility of exploiting the IHT of the LMD process for the production of samples that are precipitation strengthened

during the additive manufacturing process without need for any further heat treatment.

Acta Materialia 129 (2017) 52-60

Acta Mater 2017 Additive Manufacturing M[...]

PDF-Dokument [2.4 MB]