Role of the pellets in hydrogen-based direct reduction of iron oxides

Steel production causes a third of all industrial CO2 emissions due to the use of carbon-based substances as

reductants for iron ores, making it a key driver of global warming. Therefore, research efforts aim to replace these reductants with sustainably produced hydrogen. Hydrogen-based direct reduction (HyDR) is an

attractive processing technology, given that direct reduction (DR) furnaces are routinely operated in the steel industry but with CH4 or CO as reductants. Hydrogen diffuses considerably faster

through shaft-furnace pellet agglomerates than carbon-based reductants. However, the net reduction kinetics in HyDR remains extremely sluggish for high-quantity steel production, and the hydrogen consumption exceeds the

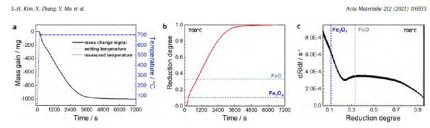

stoichiometrically required amount substantially. Thus, the present study focused on the improved understanding of the influence of spatial gradients, morphology, and internal microstructures of

ore pellets on reduction efficiency and metallization during HyDR. For this purpose, commercial DR pellets were investigated using synchrotron high-energy X-ray diffraction and electron microscopy in

conjunction with electron backscatter diffraction and chemical probing. Revealing the interplay of different phases with internal interfaces, free surfaces, and associated nucleation and growth

mechanisms provides a basis for developing tailored ore pellets that are highly suited

for a fast and efficient HyDR.

International Journal of Minerals , Metallurgy and Materials

Volume 29, Number 10, October 2022, Page 1901

https://doi.org/10.1007/s12613-022-2440-5

Hydrogen-based direct reduction of iron [...]

PDF-Dokument [3.8 MB]

We studied the role of the pellets in this process to gain further insights into

the influence of pellet morphology and its internal microstructure on the overall reduction efficiency and metallization.

For this purpose, commercial direct reduction (DR) pellets were investigated using synchrotron high-energy X-ray diffraction (HEXRD) and scanning electron microscopy in conjunction

with electron backscatter diffraction (EBSD) and

energy-dispersive X-ray spectroscopy (EDX). This approach revealed the microstructural morphology and spatial gradients of the phase transformations during the HyDR and the interplay

of different phases with the internal interfaces. The obtained results can guide the development of next-generation reactors and pellet feedstock that are better suited for a fast and

efficient HyDR to make ironmaking affordably carbon free.

https://doi.org/10.1016/j.actamat.2022.117899

1359-6454/©2022ActaMaterialiaInc

Acta Mater 2022 Chemo-mechanical phase-f[...]

PDF-Dokument [4.6 MB]

Steel is the most important material class in terms of volume and environmental impact. While it is a sustainability enabler, for instance through lightweight design, magnetic devices, and efficient turbines, its primary production is not. Iron is reduced from ores by carbon, causing 30% of the global CO 2 emissions in manufacturing, qualifying it as the largest single industrial greenhouse gas emission source. Hydrogen is thus attractive as alternative reductant.

Role of microstructure in hydrogen-based[...]

PDF-Dokument [1.3 MB]