What are TWIP High Entropy Alloys?

Preconditon for the design of twinning-induced plasticity high entropy alloys: drop the strict equimolar mixing rule!

Theoretical calculations have revealed that the strict rule of maximizing the configurational entropy is not a sufficent criterion to form massive solid

solutions. This opened the pathway towards designing non-equiatomic high entropy alloys. The plain

reason for this is that the shape of the entropy curve as a function of chemical composition assumes for most transition metal mixtures a rather flat course so that even larger compositional deviations from the originally

strict equiatomic alloying rule yield the quite similar entropy values as an equiatomic solid solution mix.

We refer to these materials as non-equiatomic high entropy alloys.

This thermodynamic relaxation of the originally quite strict high entropy alloy rule opens up a huge and very flexible alloying window for realizing true single phase states and it allows for corresponding property tuning via cimpositional modification for example of the stacking fault energy.

Reasons and alloy design approaches for deviating from equimolar composition for high entropy alloys

The devleopment of equi-atomic solutions is not in all cases the optimal design approach for solid high or medium entropy alloys.

There are several reasons to relax the constraint of using equi-atomic solid solutions among which the most important one are to avoid precipitates (if undesired) and to tune the stacking fault energy (for instance to enable TWIP or TRIP high entropy alloys).

The use of interstitial alloying elements in High and Medium Entropy Alloys

The high and medium entropy alloy design rules can be modified to additionally consider interstitial alloying elements, specifically solute C, N, O, H and B. Interstitial elements, specifically C and N, offer very interesting alloying options with respect to stabilizing fcc solid solutions as is also expressed by their effect on the valence electron concentration (VEC).

Yet, concentration of these interstitials must be well adjusted (to rather modest doses) as equiatomic fractions of C, N or B lead to massive formation of carbides, nitrides and borides, hence, the equiatomic composition rule makes not so much sense for the case of interstitials as the main design aim in this field lies in solid solution blending.

Mixing entropy changes in High Entropy Alloys as a function of small composition variations

Deviating from the classical multi-component concept means to use compositionally more lean and non-equiatomically alloys.

This approach should be considered under the umbrella of the High Entropy Alloy design approach owing to the fact that in many transition metal alloy solid solutions the shape of the configurational entropy as a function of chemical composition assumes a relatively flat and compositionally wide plateau in high dimensional phase diagrams.

This means that the entropy curve close to the maximum has in multicomponent alloys only a rather weak maximum and no steep changes, except for the case of very small concentrations (where the gain in configurational entropy upon composoition change can become near-infinite).

This fact suggests that entropy-based stabilization of massive solid solutions can also be achieved for non-equiatomic quinary and quaternary alloy compositions. This modifies the original high entropy alloying concept, where none of the alloying elements was meant to dominate, into a class of e.g. Fe-based or Ni-based or Ti- based materials.

This opening rule of the otherwise rather strict design rules allows for efficient tuning of the alloys' stacking fault energy, allowing the design of effective TRIP and TWIP High and Medium Entropy Allloys.

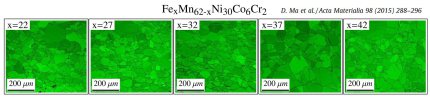

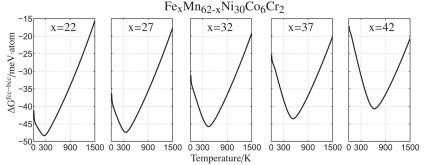

The aim of this study was to investigate the phase stability of non-equiatomic FeMnNiCoCr based high entropy alloys. Another aim is to systematically and critically assess the predictive capability of the CALPHAD approach for such high entropy alloy systems. We find that the CALPHAD simulations provide a very consistent assessment of phase stability yielding good agreement with experimental observations. These includethe equilibrium phase formation at high temperatures, the constituent phases after non-equilibrium solidification processes, unfavorable segregation profiles inherited from solidification together with the associated nucleation and growth of low temperature phases, and undesired martensitic transformation effects. Encouraged by these consistent theoretical and experimental

Acta Mater 98 (2015) 288 Non-Equiatomic [...]

PDF-Dokument [636.7 KB]

Twinning-induced plasticity high entropy alloys

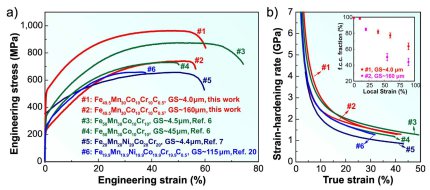

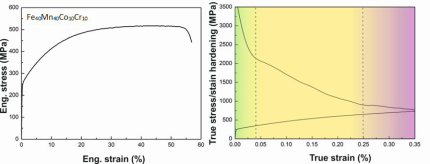

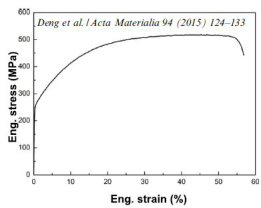

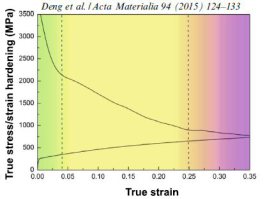

With this quite substantial additional compositional degree of freedom a hure realm of corresponding alloy variations can be explored to optimize the stacking fault energy and to transfer the excellent nanotwinning induced cryogenic mechanical behavior observed also to room temperature. We have demonstrated this approach via the design of a lean (i.e. in terms of Co, Cr and especially Ni content with respect to the equiatomic five-component alloy) twinning-induced plasticity high entropy alloy (TWIP-HEA), Fe40Mn40Co10Cr10 with excellent room temperature mechanical properties that are comparable to those of advanced TWIP steels.

Acta Materialia 94 (2015) 124: Here ee introduce a non-equiatomic Fe40Mn40Co10Cr10 high entropy alloy that is designed to undergo

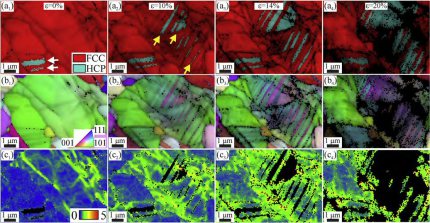

mechanically-induced twinning upon deformation at room temperature. Microstructure characterization shows a homogeneous fcc structured single phase solid solution in the as-cast, hot-rolled and homogenized states. Investigations of the deformation

substructures at specific strain levels with electron channeling contrast imaging (ECCI) combined with EBSD reveal a clear change in the deformation mechanisms of the designed alloy starting from dislocation slip to twinning as a function of strain.

Acta Materialia 94 (2015) 124 Twinning I[...]

PDF-Dokument [1.4 MB]

TWIP and TRIP High Entropy Alloys 2019 M[...]

PDF-Dokument [3.1 MB]

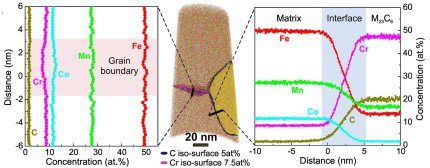

Interstitial TWIP high-entropy alloy

After our recent development of interstitial high-entropy alloys (iHEAs) we have studied and optimized these matierlals further to achieve alloys with an enhanced combination of strength and

ductility. In the current interstitial high entropy alloy these properties are attributed to dislocation hardening, deformation-driven athermal phase transformation from the face-centered cubic

(FCC) gamma matrix into the hexagonal close packed (HCP) ε phase, stacking fault formation, mechanical twinning and precipitation hardening. For gaining a better understanding of these

mechanisms as well as their interactions direct observation of the deformation process is required. For this purpose, an iHEA with nominal composition of Fe-30Mn-10Co-10Cr-0.5C (at. %) was

produced and investigated in our group via in-situ and interrupted in-situ tensile testing

in a scanning electron microscope (SEM) combining electron channeling contrast imaging (ECCI) and electron backscatter diffraction (EBSD) techniques. The results reveal that the iHEA is deformed

by formation and multiplication of stacking faults along {111} microbands. Sufficient overlap of stacking faults within microbands leads to intrinsic nucleation of HCP ε phase and

incoherent annealing twin boundaries act as preferential extrinsic nucleation sites for HCP ε formation. With further straining HCP ε nuclei grow into the adjacent deformed FCC gamma

matrix. Gamma regions with smaller grain size have higher mechanical stability against phase transformation. Twinning in FCC gamma grains with a size of ~10 mm can be activated at room

temperature at a stress below ~736 MPa.

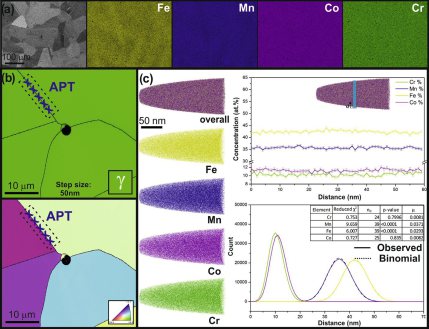

High-entropy alloys (HEAs) consisting of multiple principle elements provide an avenue for realizing exceptional mechanical, physical and chemical properties. We report a novel strategy for designing a new class of HEAs incorporating the additional interstitial element carbon. This results in joint activation of twinning- and transformation-induced plasticity (TWIP and TRIP) by tuning the matrix phase’s instability in a metastable TRIP-assisted dual-phase HEA. Besides TWIP and TRIP, such alloys benefit from massive substitutional and interstitial solid solution strengthening as well as from the composite effect associated with its dual-phase structure. Nanosize particle formation and grain size reduction are also utilized. The new interstitial TWIP-TRIP-HEA thus unifies all metallic stre

Li 2017 Scientific Reports Interstitial [...]

PDF-Dokument [2.8 MB]

strength ductility high entropy alloy al[...]

PDF-Dokument [4.0 MB]

Reducing alloy costs for TWIP and TRIP High and Medium Entropy Alloys

An important motivation for designing compositionally simplified high entropy alloys lies in reducing alloying costs. Any material that is being designed and meant to be used for specific applications must pass the critical test whether the respective alloying elements and their quantities are indeed required to reach a design target or not. If not, their respective alloying content can be reduced. Examples are typical bounds known for established commercial alloys such as a certain Cr and Mo content in stainless steels for achieving sufficient pitting and corrosion resistance; specific values of Ni and Al in superalloys required to arrive at the characteristic matrix – precipitate structure; a certain Cu content for precipitating Guinier-Preston zones in age hardening aluminum alloys; or a minimum required Nb or Ta content to stabilize elastically compliant bcc Ti alloys. In all these metallurgical examples the respective alloying elements are only added to the content that is required for achieving the aims described, but the alloying content is not increased beyond these values if not serving a specific thermodynamic, kinetic or property function. However, in cases where a near-maximum value of the configurational entropy can be realized at smaller alloying content, i.e. before reaching an equiatomic composition, no need exists to alloy further. In other words the presence of a long and flat compositional entropy plateau enables to exploit a wider mixing range and less consumption of expensive alloying ingredients when designing high entropy alloys.

Frontiers Materials 2018 TRIP-Assisted D[...]

PDF-Dokument [5.5 MB]

Combination of the TRIP-like phase transformation and twinning mechanisms (TWIP effect) in an interstitial High Entropy Alloy

In this project an interstitial high-entropy alloys (iHEAs) was studied which exhibits an enhanced combination of strength and ductility. These properties are attributed to dislocation hardening,

deformation-driven athermal phase transformation from the face-centered cubic (FCC) gamma matrix into the hexagonal close-packed (HCP) ε phase, stacking fault formation, mechanical twinning and

precipitation hardening. For gaining a better understanding of these mechanisms as well as their interactions direct observation of the deformation process is required. For this purpose, an

iHEA with nominal composition of Fe-30Mn-10Co-10Cr-0.5C (at. %) was produced and investigated via in-situ and interrupted in-situ tensile testing in a scanning electron microscope (SEM) combining

electron channeling contrast imaging (ECCI) and electron backscatter diffraction (EBSD) techniques. The results reveal that the iHEA is deformed by

formation and multiplication of stacking faults along {111} microbands. Sufficient overlap of stacking faults within microbands leads to intrinsic nucleation of HCP ε phase and incoherent

annealing twin boundaries act as preferential extrinsic nucleation sites for HCP ε formation. With further straining HCP ε nuclei grow into the adjacent deformed FCC gamma matrix. Gamma

regions with smaller grain size have higher mechanical stability against phase transformation. Twinning in FCC ggrains with a size of ~10 mm can be activated at room temperature at a stress

below ~736 MPa. With increasing deformation, new twin

lamellae continuously nucleate. The twin lamellae grow in preferred directions driven by the motion of the mobile partial dislocations. Owing to the individual grain size dependence of the

activation of the dislocation-mediated plasticity, of the athermal phase transformation and of mechanical twinning at the different deformation stages, desired strain hardening profiles can

be tuned and adjusted over the entire deformation regime by adequate microstructure design, providing excellent combinations of strength and ductility.

Acta Mater 2018 TWIP and TRIP effect in [...]

PDF-Dokument [789.8 KB]

Raabe_et_al-2015-steel_research_internat[...]

PDF-Dokument [1.8 MB]

How design a lean twinning-induced plasticity (TWIP) high entropy alloy with lower alloying costs

A high entropy alloy with mechanically-induced twinning upon deformation (TWIP effect) can be made with the composition Fe40Mn40Co10Cr10. It has FCC structure and is single phase.

Investigation of the deformation microstructures at specific strain levels with electron channeling contrast imaging (ECCI) and EBSD reveal a change in mechanisms from dislocation slip to twinning as a function of strain. This shows that despite decreased configurational entropy compared to that of an equiatomic, multi-phase Fe25Mn25Co25Cr25 alloy, a single phase microstructure is achieved. Also, in contrast to the equiatomic FeMnNiCoCr system where the deformation twins only appear at cryogenic temperatures, deformation twins form at room temperature. Despite the decreased contribution of solid solution strengthening, the tensile properties of this lean alloy at room temperature are found to be comparable to that of the well-studied five component FeMnNiCoCr system.

Acta Materialia 94 (2015) 124–133

Acta Materialia 94 (2015) 124 Twinning I[...]

PDF-Dokument [1.4 MB]

![Twinning-induced plasticity high entropy alloys (Acta Mater 94 (2015) 124): Deformation twins at 45% true strain in Fe40Mn40Co10Cr10 revealed by TEM: (a) dark field micrograph with beam direction [002]T; (b) selected-area diffraction pattern.](https://www.dierk-raabe.com/s/cc_images/cache_2478030294.jpg?t=1518767425)