What are High Entropy Alloys and why are they interesting?

Since the early bronze age, humans have been tuning the properties of materials by adding alloying elements. For example, a few percent by weight of copper was added to silver to produce sterling silver for coinage a thousand years ago, because pure silver was too soft. Examples from the modern era include steels that consist primarily of iron alloyed with carbon and chromium for strength and corrosion resistance, respectively, and copper alloyed with beryllium to make it strong and non-sparking for use in explosive environments.

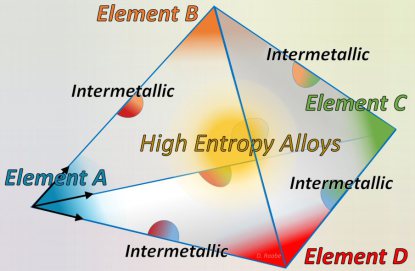

With few exceptions, the basic alloying strategy of adding relatively small amounts of secondary elements to a primary element has remained unchanged over millennia. This means that composition adjustment of metallic alloys has long been used to lend desirable properties to materials. Typically, in classical metallurgical alloys such as steels or Aluminium alloys, it involves the addition of relatively small amounts of secondary elements to a primary element (e.g. Fe plus C or Al plus Cu). For the past decade and a half, however, a new alloying strategy that involves the combination of multiple principal elements in high concentrations to create new materials called high-entropy alloys has been emerging. High-entropy alloys have greatly expanded the compositional space for alloy design. The multidimensional compositional space that can be tackled with this approach is practically limitless, and only very small compositional regions have been investigated so far. Nevertheless, a few high-entropy alloys have already been shown to possess good mechanical, magnetic and invar properties, exceeding in part those of some conventional alloys, and more such high-entropy alloys are likely to be discovered in the future.

Combinatorial synthesis and probing approaches to discover new High Entropy Alloys

Combinatorial approaches based on high-throughput synthesis and characterization of multiple alloy compositions, have been frequently used in metallurgy to rapidly determine phase diagrams in

multi-component spaces and screen physical and mechanical properties. At least portions of the available compositional space can be surveyed by the fabrication and subsequent characterization of many

alloy variants simultaneously.

Among the different combinatorial methods, four approaches have proven particularly useful for HEAs: bulk rapid alloy prototyping (Springer), diffusion couples and diffusion multiples (Zhao), laser

and electron additive manufacturing of compositionally graded samples (Knoll), and combinatorial thin-film materials libraries (Ludwig).

Rapid alloy prototyping is a combinatorial bulk processing approach in which secondary specimens can be cut from processed sheets, for example for uniaxial tensile testing. The method essentially

comprises fast bulk processing steps such as slab or strip casting, hot rolling, homogenization, cold rolling and recrystallization. Each casting can in itself be compositionally homogeneous or

contain chemical gradients along the casting direction, introduced for instance by gradually blending a base alloy during an ongoing continuous casting process. This approach has the advantage of

providing homogeneous bulk samples with representative microstructures, but is slow compared to thin film combinatorial methods, which can routinely synthesize multiple thin-film materials libraries

by depositing thin-film composition gradients across a substrate in a single multi-target sputter experiment. Diffusion multiples in which specimens with different compositions are brought together

at elevated temperatures to produce chemical gradients across their interfaces and compositionally graded additive manufacturing methods are located between rapid alloy prototyping and thin-film

methods and provide access to mesoscopic and millimeter-sized specimens for subsequent property assessment.

Metallographic or XRD characterization of these miniature samples should then be used to yield important information about the phases and microstructures present. For small-scale combinatorial

samples, nano- and micro-indentation testing can be used for probing the hardness of the alloys. Disadvantages of small-scale combinatorial methods include limited product size, sometimes too

small for a comprehensive screening of functional and/or mechanical properties (such as strain hardening, ductility or fracture toughness), and resulting materials that are too artificial in terms of

microstructure, morphology, size, distribution and orientation of the phases present. Nevertheless, such combinatorial approaches can be valuable in eliminating impractical materials, such as

hopelessly brittle alloys, and thus can play a key role in reducing the number of alloys to be considered in larger-scale evaluations, such as uniaxial tensile or fracture toughness tests, which are

performed on more realistic product forms.

Alloying in metallurgical research has long been used to equipp materials with desirable properties. Compositoinal alloy design usually involves the addition of relatively small amounts of secondary elements to a primary element and subject the material then to often complex processing pathways for microstructure tuning. The chemical and microstructural design must go hand in hand because compositional variation allows to access the tuning of the occurrence and behaviour of certain lattice defects such as for instance the stacking-fault energy. Through this approach, thermodynamically guided strain-hardening engineering can be accomplished, enabling the activation of beneficial strain-hardening features, including stack-

ing faults, reactions among partial dislocations, complex dislocation

Nature Materials Reviews Aug 2019 High-e[...]

PDF-Dokument [2.4 MB]

Nature, June 2016

Li et al Nature June 2016 Metastable hig[...]

PDF-Dokument [6.0 MB]

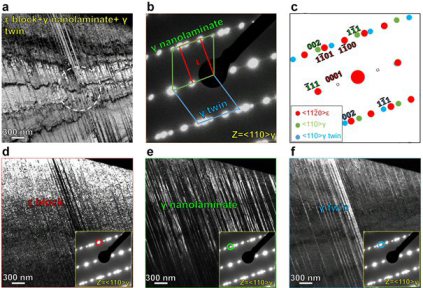

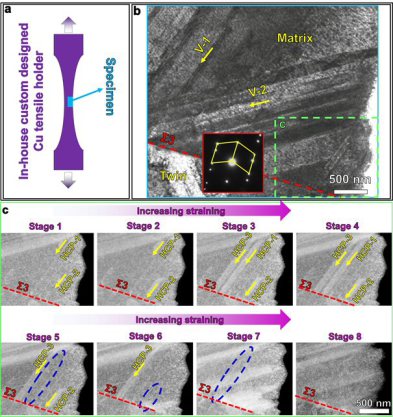

Bidirectional transformation (B-TRIP) enables hierarchical nanolaminate dual-phase high-entropy alloys

Microstructural length scale refinement is among the most efficient approaches to strengthen metallic materials. Conventional methods for refining microstructures generally involve grain size reduction via heavy cold working, compromising the material’s ductility. Here we report a fundamentally new approach that allows load-driven formation and permanent refinement of a hierarchical nanolaminate structure in a novel high-entropy alloy containing multiple principal elements. This is achieved by triggering both, dynamic forward transformation from a faced-centered cubic (FCC) γ matrix into a hexagonal close-packed (HCP) ε nanolaminate structure and the dynamic reverse transformation from ε into γ. We refer to this new mechanism as Bidirectional Transformation Induced Plasticity effect (B-TRIP), which is enabled through a near-zero yet positive stacking fault energy of γ. Modulation of directionality in the transformation is triggered by local dissipative heating and local micromechanical fields. The simple thermodynamic and kinetic foundations for the B-TRIP effect render this approach generally suited for designing metastable strong and ductile bulk materials with hierarchical nanolaminate substructures.

Bidirectional TRIP effect High Entropy A[...]

PDF-Dokument [1.6 MB]

Here we introduce a new class of high-entropy alloys (HEAs), i.e., quinary (five-component) dual-phase (DP) HEAs revealing transformation-induced plasticity (TRIP), designed by using a quantum mechanically based and experimentally validated approach.

Acta Materialia 2017 Ab initio design qu[...]

PDF-Dokument [4.9 MB]

https://www.nature.com/articles/s41467-019-10012-7

Oh_et_al-2019-Nature_Communications.pdf

PDF-Dokument [1.5 MB]

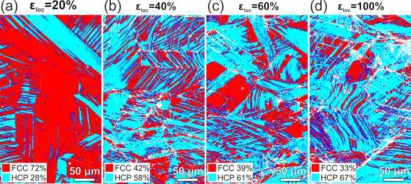

High-entropy alloys (HEAs) consisting of multiple principle elements provide an avenue for realizing exceptional mechanical, physical and chemical properties. We report a novel strategy for designing a new class of HEAs incorporating the additional interstitial element carbon. This results in joint activation of twinning- and transformation-induced plasticity (TWIP and TRIP) by tuning the matrix phase’s instability in a metastable TRIP-assisted dual-phase HEA. Besides TWIP and TRIP, such alloys benefit from massive substitutional and interstitial solid solution strengthening as well as from the composite effect associated with its dual-phase structure. Nanosize particle formation and grain size reduction are also utilized.

Li_et_al-2017-Scientific_Reports interst[...]

PDF-Dokument [3.0 MB]

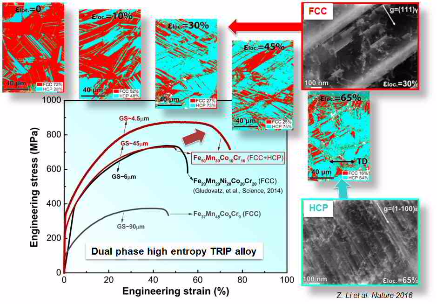

This is a systematic microstructure oriented mechanical property investigation for a newly developed class of transformation-induced plasticity-assisted dual-phase high-entropy alloys (TRIP-DP-HEAs) with varying grain sizes and phase fractions. The DP-HEAs in both, as-homogenized and recrystallized states consist of a face-centered cubic (FCC) matrix containing a high-density of stacking faults and a laminate hexagonal close-packed (HCP) phase.

Acta Materialia 2017 TRIP dual phase hig[...]

PDF-Dokument [5.8 MB]

The strength and formability of metals can deteriorate when they contain hydrogen, leading to unpredictable failure, an effect called hydrogen embrittlement. Here we

report that hydrogen in an equiatomic CoCrFeMnNi high-entropy alloy (HEA) leads not to catastrophic weakening, but instead increases both, its strength and ductility. While HEAs originally aimed at entropy-driven phase stabilization, hydrogen blending acts opposite as it reduces phase stability. This effect, quantified by the alloy’s stacking fault energy, enables nanotwinning which increases the material’s work-hardening. These results turn a bane into a boon: hydrogen does not generally act as

a harmful impurity, but can be utilized for tuning beneficial hardening mechanisms.

Luo_et_al-2017-Scientific_Reports.pdf

PDF-Dokument [2.6 MB]

Microstructural length-scale refinement is among the most efficient approaches to strengthen metallic materials. Conventional methods for refining microstructures generally involve grain size reduction via heavy cold working, compromising the material’s ductility. Here, a fundamentally new approach that allows load-driven formation and permanent refinement of a hierarchical nanolaminate structure in a novel high-entropy alloy containing multiple principal elements is reported. This is achieved by triggering both, dynamic forward transformation from a faced-centered-cubic γ matrix into a hexagonal-close packed ε nanolaminate structure and the dynamic reverse transformation from ε into γ. This new mechanism is referred to as the “bidirectional transformation induced plasticity” (B-

Bidirectional TRIP effect in High Entrop[...]

PDF-Dokument [5.4 MB]

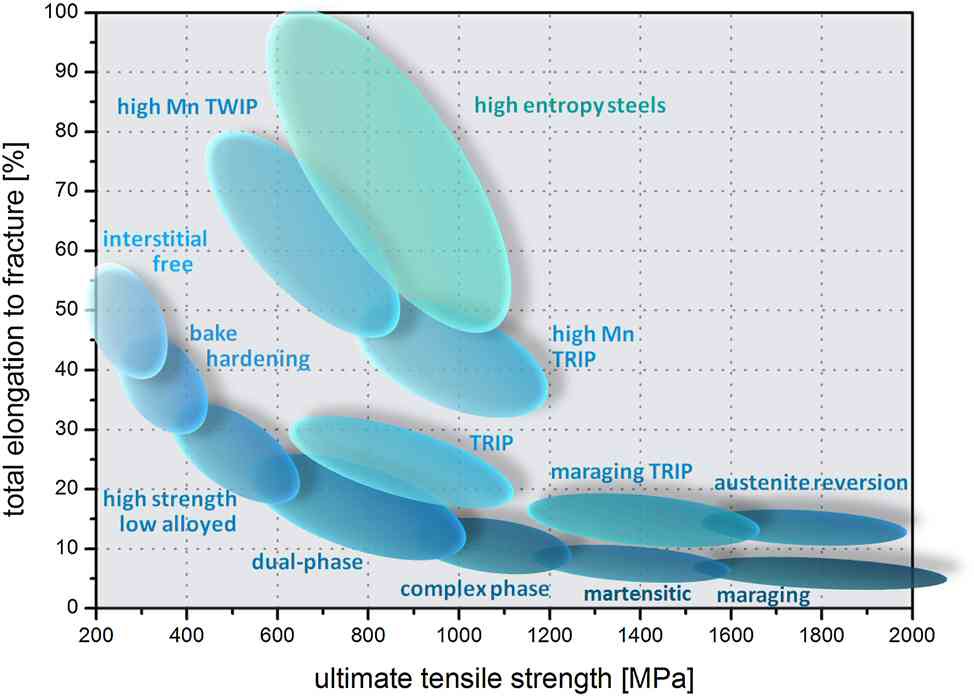

Why do we develop new alloys ?

Metals have been mankind’s most essential materials for thousands of years; however, their use is affected by ecological and economical concerns. Alloys with higher strength and

ductility could alleviate some of these concerns by reducing weight and improving energy efficiency. However, most metallurgical mechanisms for increasing strength lead to ductility

loss, an effect referred to as the strength–ductility trade-off. Here we present a metastability-engineering

strategy in which we design nanostructured, bulk high-entropy alloys with multiple compositionally equivalent high-entropy phases.

What are High Entropy Alloys ?

Currently there is no generally consistent definition of High Entropy Alloys. Yeh originally defined High Entropy Alloys as metallic blends consisting at least 5 elements with atomic concentrations between 5 and 35 atomic percent. It was later suggested though that this definition could be expanded. Otto et al. suggested that only alloys that form a solid solution with no intermetallic phases should be considered true high-entropy alloys, as the formation of ordered phases decreases the entropy of the system. Other author groups have described 4-component alloys as high-entropy alloys while others have suggested that alloys meeting the other requirements of High Entropy Alloys, but with only 2–4 elements or a value of the mixing entropy between R and 1.5R should be considered as 'medium-entropy' alloys.

Why should the original High Entropy Alloy design rules be developed further ?

High-entropy alloys were originally proposed to benefit from phase stabilization through configurational entropy maximization. Yet, in our current work, motivated by recent work that relaxes the strict restrictions on high-entropy alloy compositions by demonstrating the weakness of this connection, the concept is overturned. We decrease phase stability to achieve two key benefits: interface hardening due to a dual-phase microstructure (resulting from reduced thermal stability of the high-temperature phase; and transformation-induced hardening (resulting from the reduced mechanical stability of the room-temperature phase. This combines the best of two worlds: extensive hardening due to the decreased phase stability known from advanced steels and massive solid-solution strengthening of high-entropy alloys. In our transformation-induced plasticity-assisted, dual-phase high-entropy alloy (TRIP-DP-HEA), these two contributions lead respectively to enhanced trans-grain and inter-grain slip resistance, and hence, increased strength. Moreover, the increased strain hardening capacity that is enabled by dislocation hardening of the stable phase and transformation-induced hardening of the metastable phase produces increased ductility. This combined increase in strength and ductility distinguishes the TRIP-DP-HEA alloy from other recently developed structural materials. This metastabilityengineering

strategy should thus usefully guide design in the near-infinite compositional space of high-entropy alloys.

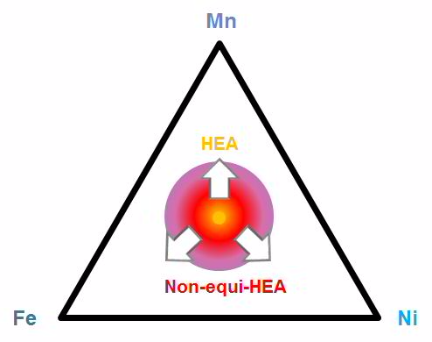

Why do we develop non-equi-compositional High Entropy Alloys?

High-entropy alloys (HEAs) are of high interest due to their inherent immense compositional variability enabling design of novel materials with interesting or even so far entirely undiscovered mechanical and / or functional properties. HEAs were originally proposed to contain multiple principal elements in equimolar or near-equimolar ratios with maximized configurational entropy to stabilize single-phase structures. Following this concept, many types of single-phase HEAs have been developed with different crystal structures such as face-centered cubic (FCC), body-centered cubic (BCC) and hexagonal close-packed (HCP).

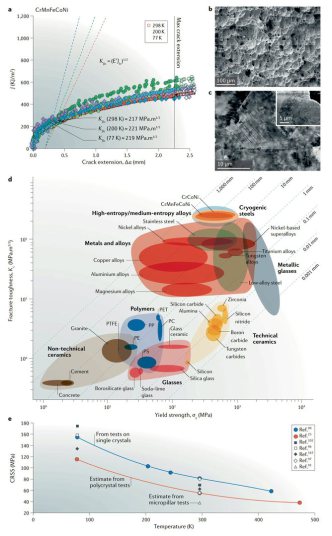

Particularly, the CoCrFeMnNi HEA with single FCC phase at room temperature exhibits excellent mechanical properties under various temperatures, specifically at very low (so called cryogenic) temperatures.

More recently, based on the fact that maximized configurational entropy is not the sole factor to determine phase stability of HEAs, and due to the demand for further improving mechanical properties of HEAs, a novel design strategy has been proposed to introduce the transformation-induced plasticity (TRIP) effect into HEAs. The resulting alloys consist of a high-entropy dual-phase (DP) structure and reveal both, exceptional strength and ductility. The new alloys (see papers above) combine the massive substitutional solid-solution strengthening effect inherent in HEAs with the TRIP effect known from certain high strength steels. This leads to improved strength and ductility compared to the above-mentioned single-phase HEAs. However, the new alloy design concept, i.e., TRIP-DP-HEAs, had before only been realized for the quaternary FeMnCoCr system. Hence, it is promising to explore also quinary systems with more components and presumably larger solid-solution strengthening which can undergo TRIP.

The TRIP phenomenon is mainly determined by the value of the stacking fault energy (SFE), i.e. the energy carried by the interruption of the normal stacking sequence. The SFE is a key atomistic quantity determining whether a material reveals transformation or twinning induced plasticity (TWIP). A low SFE results into decreased cross-slip and dislocation climb. It also can affect the dislocation core properties and hence influence their mobility. The SFE, which is related to the thermal HCP-FCC phase stability, is directly accessible by atomistic simulations and therefore a central quantity linking theory and experiment. Challenges associated with SFE simulations for HEAs are that: i) small changes of the order of a few ~mJ/m2 can be decisive for the dominant deformation mechanism (TRIP vs. TWIP), ii) SFEs are strongly temperature dependent, and iii) the large configuration space due to the inherent multi-element character of HEAs. For designing alloys with optinal SFE, enabling eitehr the TRIP or TWIP effects, require tuning alloy composition also outside of the original HEA design rules.

High entropy alloys: design, metallurgy, synthesis, properties

Metallic alloys are often based on one or two major alloying elements with one constituent being the principal (solvent) element and the other constituents in small proportion (solutes) acting as alloying elements for tuning the desired properties. A new class of alloys referred to as 'High Entropy Alloys (HEA)' has been suggested which is defined as having at least five principal elements in equi-atomic or near equi-atomic ratios. The initial rationale behind this design concept is to maximize the configurational entropy of mixing with the aim to stabilize a solid solution based alloy with high hardness, strength and stability at high temperatures. Formation of ordered intermetallics and dissociation into multiple phases is usually not desired. Zhang et al. studied the solid solution phase formation rules for HEAs and stated that for high entropy solid solution the absolute value of the enthalpy of mixing should lie between -2.685×δ -2.54 <ΔHmix< -1.28×δ + 5.44 kJ/mol. This relation establishes a phenomenological link between the mixing enthalpy and the atomic size parameter (δ). The authors also suggested that δ should be less than 4.6 and the mixing entropy (ΔSmix) should be greater than 1.61 R, where R is the gas constant. Sheng et al. studied the effect of valence electron concentration (VEC) on the stability of bcc or fcc solid solutions in HEAs. Based on the calculations for different HEA compositions, it was reported that for alloys with VEC ≥ 8 fcc phases are stable and bcc phases are reported to be stable for VEC ≤ 6.87.

Several studies have been carried out on hexanary alloy systems such as AlCoCrCuFeNi due to their favorable combination of high hardness, compressive strength and

resistance to softening even at 800 °C. Many reports have shown that HEAs produced by conventional metallurgical processing routes such as casting tend to form solid solution phases

either with face-centered cubic (fcc) or body-centered cubic (bcc) structures or mixtures of both. Singh et al. studied the microstructure of a multi-component AlCoCrCuFeNi HEA in

the as-cast and splat-quenched condition using transmission electron microscopy (TEM) and atom probe tomography

(APT). They observed that the splat-quenched alloy had an imperfectly ordered bcc phase whereas the conventionally cast alloy formed multiple bcc and fcc phases with a dendritic

microstructure within the same alloy. Within these phases local compositional fluctuations and segregations within the dendrites for the same and similar compositions were observed at nanometer scale

by APT. The splat-quenched equi-atomic AlCoCrCuFeNi HEA exhibited better soft magnetic properties than the as-cast material. It was shown that the

Cr-Fe-Co rich regions in the as-cast alloy underwent spinodal decomposition upon ageing which improved the magnetic properties.

Nanostructured single phase solid solution formation in HEAs synthesized by mechanical alloying has been reported recently.

The advantage of powder processing is that the alloys containing low/high melting point elements as constituents can be produced economically compared to other processing routes such as casting.

Varalakshmi et al. studied the phase formation in nanocrystalline AlCrCuFeTiZn HEA from binary to hexanary compositions using X-ray diffraction (XRD), scanning electron microscopy

(SEM) and TEM. The alloy in the as-milled condition exhibited a single bcc phase with crystallite size of about 10 nm. The high entropy solid solution was stable even after annealing at 800 °C for 1

hr and also possessed very high hardness of about 2 GPa. Similar results were obtained for different hexanary alloy systems such as AlCoCuNiTiZn and CoCrFeMnNiW [13]. Also, dissociation into multiple

phases during sintering of mechanical alloyed AlCoCrCuFe and CoCrCuFeNi HEA powders have been reported, where the mixing enthalpy was found to play an important role in the

segregation of a Cu-rich fcc phase. However, detailed studies on the microstructure evolution and phase formation in nanocrystalline HEAs have not yet been conducted. Moreover, the stability of

nanocrystalline phases at high temperatures has not yet been well understood.

converter atomic percent to weight perce[...]

Microsoft Excel-Dokument [64.0 KB]

From High-Entropy Alloys to High-Entropy Steels

Dierk Raabe, Cemal Cem Tasan, Hauke Springer, Michael Bausch

steel research int. 86 (2015) No. 10 pages 1127-1138

Raabe steel research int. vol 86 (2015) [...]

PDF-Dokument [1.8 MB]

Entropy 2016, 18, 321; doi:10.3390/e18090321

Lattice Distortions in the FeCoNiCrMn Hi[...]

PDF-Dokument [1.1 MB]

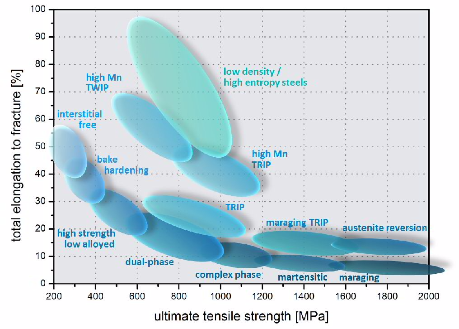

What are High Entropy Steels ?

Inspired by high-entropy alloys, we study the design of steels that are based on high configurational entropy for stabilizing a single-phase solid solution matrix. The focus is placed on the system Fe–Mn–Al–Si–C but we also present trends in the alloy system Fe–Mn–Al–C. Unlike in conventional high-entropy alloys, where five or more equiatomically proportioned components are used, we exploit the flat configurational entropy plateau in transition metal mixtures, stabilizing solid solutions also for lean, non–equiatomic compositions. This renders the high-entropy alloying concept, where none of the elements

prevails, into a class of Fe-based materials which we refer to as high-entropy steels. A point that has received little attention in high-entropy alloys is the use of

interstitial elements. Here, we address the role of C in face-centered cubic solid solution phases. High-entropy steels reveal excellent mechanical properties, namely, very high ductility

and toughness; excellent high rate and low-temperature ductility; high strength of up to 1 GPa; up to 17% reduced mass density; and very high strain hardening. The

microstructure stability can be tuned by adjusting the stacking fault energy. This enables to exploit

deformation effects such as the TRIP, TWIP, or precipitation determined mechanisms.

What are non-equiatomic High Entropy Alloys? Rapid alloy screening and property-oriented design

The High Entropy Alloy (HEA) concept has attracted significant interest in recent years due to the novelty of the underlying alloy design principle and the promising mechanical properties of the massive solid solution microstructures [1,2]. In general, the concept inherits the idea of producing bulk crystalline alloys composed of multiple components being added in proportions that are far beyond their binary solid solubility limits, yet yielding a single phase solid solution [3,4]. While in some cases the solid solutions formed possess simple crystal structures such as face-centered cubic (fcc) and body centered cubic (bcc) [5,6] and fulfill the expectations of combining high strength with good ductility [7], these successful cases constitute only a very small fraction of the

significant efforts to experimentally obtain such single phase solid solutions. The underlying reason for such limited success is the very nature of the proposed alloy

design strategy, which relies completely on the maximization of the configurational entropy [8– 11]. The original HEA approach thus imposes the

constraint of achieving this through equiatomic ratios of multiple alloying

principal elements [1,12]. A limiting criterion of this type has failed to produce consistently the desired single phase solid solution forming compositions, resulting in the emergence of

only a handful of equiatomic HEAs forming single phase solid solutions [3,13]. The most well-known of these is the equiatomic CoCr-FeMnNi introduced by

Cantor et al. [3,14–16] which forms a single

fcc phase solid solution and exhibits excellent room temperature

and cryogenic mechanical properties [17,18]. The present work aims at exploring the inherent flexibility involved in HEA design which would enable to overcome the limitations of HEA

design concept. Following such an objective three distinct non-equiatomic single phase HEAs namely, Fe40Mn27Ni26Co5Cr2, Fe40Mn40Co10Cr10 and Fe37Mn45Co9Cr9 (all in at%) were introduced

by the authors recently [19–21], which exhibit exceptional stability and tensile properties. In all of these cases, even though the major constituents of the proposed

non-equiatomic HEA are primarily the same as that of the alloy proposed by Cantor et al., the constituent proportions differ quite significantly, thus deviating from the existing HEA

design principles. In spite of the deviation, random single phase solid solution microstructures are successfully achieved. The recent investigation of Otto et al. demonstrated the weak dependence of

single phase solid solution formability on configurational entropy [22]. Also, other works revealed that the configurational entropy curve of such

materials assumes a rather flat shape so that a wide range of compositions outside of the equiatomic structure yield similar entropy values [19–21]. These results clearly show

that alloy design approaches expanding towards non-equiatomic

compositions have a great potential in opening up the applicability of HEAs for future applications as sketched in Fig. 1. To demonstrate the significance of this concept, we i)

introduce a series of such non-equiatomic high entropy alloys with varied chemical compositions; ii) demonstrate that a single phase solid solution is achieved in each of the

introduced cases; iii) validate the stability of all those single phase solid solutions at elevated temperatures; and iv) investigate the mechanical properties in terms of bulk

hardness and by tensile testing.

More specific, the high entropy alloy (HEA) concept has triggered a renewed interest in alloy design, even though some aspects of the underlying thermodynamic concepts are still under debate.

This study addresses the shortcomings of this alloy design strategy with the aim to open up new directions of HEA research targeting specifically non-equiatomic yet massively alloyed

compositions. We propose that a wide range of massive single phase solid solutions could be designed by including non-equiatomic variants. It is demonstrated by introducing a set of novel

non-equiatomic multi-component CoCrFeMnNi alloys produced by metallurgical rapid alloy prototyping. Despite the reduced configurational entropy, detailed characterization of these materials

reveals a strong resemblance to the well-studied equiatomic single phase HEA:

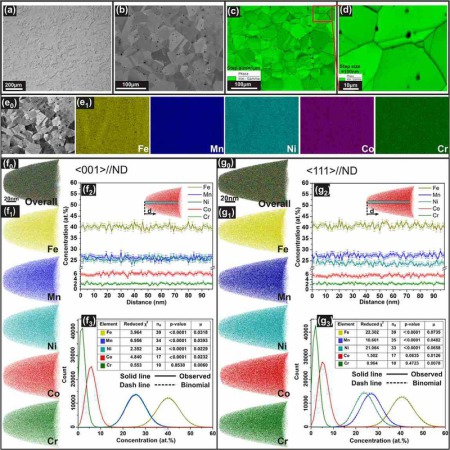

The microstructure of these novel alloys exhibits a random distribution of alloying elements (confirmed by Energy-Dispersive Spectroscopy and Atom Probe Tomography) in a single

face-centered-cubic phase (confirmed by X-ray Diffraction and Electron Backscatter Diffraction), which deforms through planar slip (confirmed by Electron-Channeling Contrast Imaging) and

leads to excellent ductility (confirmed by uniaxial tensile tests). This approach widens the field of HEAs to non-equiatomic multi-component alloys since the concept enables to tailor the

stacking fault energy and associated transformation phenomena

which act as main mechanisms to design useful strain hardening behavior.

K.G. Pradeep, C.C. Tasan, M.J. Yao, Y. Deng, H. Springer, D. Raabe

Materials Science & Engineering A 648 (2015) 183-192

Non-equiatomic high entropy alloys: Approach towards rapid alloy screening and property-oriented design

Mater Science Engin A648 (2015) 183–192 [...]

PDF-Dokument [3.8 MB]

Why develop non- equimolar and multi- phase derivatives of the Cantor alloy?

Based on the equimolar Cantor alloy, related variants with fewer alloying elements or non-equimolar compositions have been developed. One of

the rationales was to reduce the stacking- fault energy to promote TWIP and/or TRIP and, thus, to realize materials with superior strain-hardening

potential.

One effective approach has been to simply remove elements from the Cantor alloy, the most notable examples being the equiatomic, medium- entropy alloy CrCoNi and the related ultrastrong alloy

VCoNi. These single- phase FCC alloys appear to be similar to the five-element Cantor alloy, only with enhanced

strength and ductility, and toughness. At 77 K, CrCoNi (with 5–50-μm grain size) displays tensile strengths approaching 1.4 GPa, tensile ductilities of ~90% and fracture toughness values of ~270

MPa.m1/2 at crack initiation and exceeding 400 MPa.m1/2 for crack growth. Its lower stacking-fault energy and higher yield strength (compared with the Cantor alloy) allows

it to reach the twinning stress more easily, resulting in profuse nano- twinning, even at room temperature.

The twin boundaries act to arrest dislocations that impinge upon them and promote strength, yet the boundaries themselves act as pathways for the glide of partial dislocations, thus promoting ductility. Significant increases in the yield strength of the single-phase CrCoNi alloy to values exceeding 1 GPa have been achieved by cold work followed by partial recrystallization, albeit at the sacrifice of tensile ductility (which decreased to 20–30%). Precipitation of a second phase with the L12 crystal structure can also enhance the yield strength of CrCoNi (to ~800 MPa, somewhat lower than that obtained by cold work) while maintaining a tensile ductility in excess of 40%. However, because the precipitate type, volume fraction and size distribution have not been optimized, there is room to further enhance the strength–ductility combination of CrCoNi-based alloys.

Another approach involved developing a non- equiatomic Fe40Mn40Co10Cr10 HEA that deformed by planar dislocation slip early on and by mechanical

twinning at larger strains (>10%) at room temperature. In the equimolar Cantor alloy, such TWIP has only been observed under cryogenic conditions or after the application of very

high strains, as discussed before.

A group of novel, non- equiatomic, multi- component CrMnFeCoNi alloys that form planar slip substructures at strains <2% and complex cell structures with high dislocation- density

walls at higher strains (up to 45%) was also developed.

The development of metastable high-entropy dual-phase alloys help to overcome the strength–ductility trade-off

Here we present a metastability-engineering strategy in which we design nanostructured, bulk high-entropy alloys with multiple compositionally equivalent high-entropy phases. High-entropy alloys

were originally thought to benefit from phase stabilization through entropy maximization. Yet here, motivated by recent work that relaxes the strict restrictions on high-entropy alloy compositions by

demonstrating the weakness of this connection, the concept is overturned. We decrease phase stability to achieve two key benefits: interface hardening due to a dual-phase microstructure (resulting

from reduced thermal stability of the high-temperature phase); and transformation-induced hardening (resulting from the reduced mechanical stability of the room-temperature phase). This produces two

desirable strength characteristics: extensive hardening of advanced steels due to decreased phase stability and massive solid-solution strengthening of high-entropy alloys3. In our

transformation-induced, plasticity-assisted, dual-phase high-entropy alloy (TRIP-DP-HEA), ductility is also improved through an increased strain hardening capacity enabled by sequentially activated

dislocation hardening of the stable phase and transformation-induced hardening of the metastable phase. This combined increase in strength and ductility distinguishes the TRIP-DP-HEA alloy from other

recently developed structural materials (such as those with lamella structures or intermetallic phases). This metastability-engineering strategy should thus usefully guide design in the near-infinite

compositional space of high-entropy alloys.

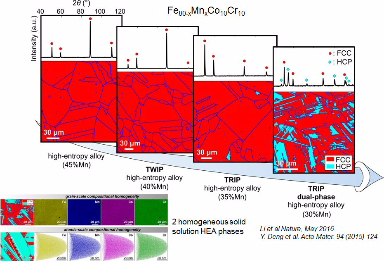

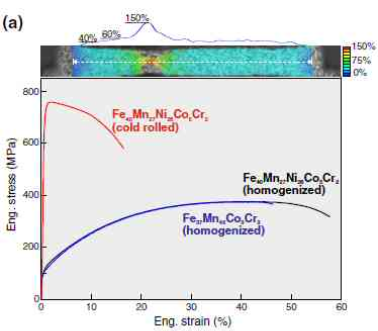

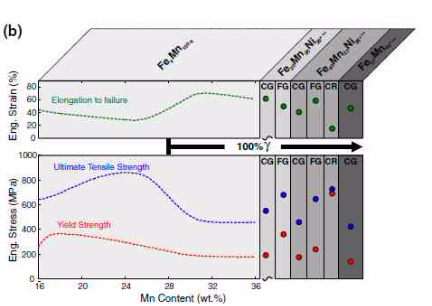

To realize the TRIP-DP-HEA concept, we switch from the equiatomic Fe20Mn20Ni20Co20Cr20 (atomic per cent, at%) system to the non-equiatomic Fe80 -xMnxCo10Cr10 (at%) system, which exhibits partial

martensitic transformation of the face-centred cubic (f.c.c.) to hexagonal close-packed (h.c.p.) phase upon cooling from the high-temperature single-phase region. This change enables development of a

dual-phase microstructure in which both phases obtain the maximum benefit of the solid-solution strengthening effect and one phase, owing to the decreased stacking fault energy, undergoes

deformation-induced displacive transformation. The partial martensitic transformation during quenching is the only possible approach that can lead to the formation of a DP-HEA with phases of

identical chemical composition (that is, high-entropy phases). The alloys were synthesized with varying Mn contents in a vacuum induction furnace using pure metals, hot-rolled to 50% thickness at 900

°C, homogenized at 1,200 °C for 2 h in an Ar atmosphere, and water-quenched. Further grain refinement was achieved by cold-rolling (to 60% thickness) and 3-min annealing at 900 °C in an Ar

atmosphere.

Microstructure characterization down to 30-nm resolution reveals that the Fe80- xMnxCo10Cr10 (at%) system indeed demonstrates the targeted change in phase stability. A single f.c.c. phase structure

was obtained when the Mn content was 45 at% and 40 at% (Fe35Mn45Co10Cr10 and Fe40Mn40Co10Cr10, respectively). These two alloys demonstrate a transition in the deformation mechanisms from

dislocation-dominated plasticity in the former to twinning-induced plasticity in the latter, confirming the targeted stability trend realized by tuning the stacking fault energy. A further decrease

to 35 at% Mn leads to traces of hexagonal close-packed (h.c.p.) phase. Finally, a decrease to 30 at% Mn (Fe50Mn30Co10Cr10) successfully produces the desired dual-phase microstructure with ~28% h.c.p.

phase.

Nature, May 2016

Li et al - Nature - 2016 - Metastable hi[...]

PDF-Dokument [6.0 MB]

Phase stability of non-equiatomic CoCrFeMnNi high entropy alloys

As outlined above High entropy alloys (HEA) are multicomponent (5 or more) massive solid solutions with an equiatomic or a near equiatomic composition. The original ideal of investigating multicomponent alloys in equal or near-equal proportions represents a new alloy exploration strategy. Instead of starting from a corner of a phase diagram with one prevalent base element, it has been suggested that new materials could be identified by directly producing equiatomic compositions with multiple components. The term ‘‘high entropy alloys’’ was introduced by Yeh et al., based on the hypothesis that the high mixing entropy would stabilize the solid solution phase over competing intermetallic and elemental phases. A well-studied HEA is the Cantor alloy i.e. Co20Cr20Fe20Mn20Ni20 (at.%) which develops a single phase fcc solid solution. Recently, it has been shown that a non-equiatomic composition of this alloy system also exhibits a single phase fcc solid solution irrespective of its slightly lower mixing entropy. The objective of this study is two-fold. One focus is the prediction and analysis of the phase stability of this alloy system i.e. FexMn62ÿxNi30Co6Cr2 (at.%, x = 22, 27, 32, 37, and 42), while varying the Fe and Mn contents, and maintaining the compositions of Cr, Co and Ni constant. The configurational entropy of these alloys ranges from 1.295 to 1.334 kB/atom (kB is the Boltzmann constant) which yields 80–83% of that in equiatomic composition (1.6094 kB/atom) as shown in Fig. 1. Another focus is to explore the feasibility of using the CALPHAD (CALculation of PHAse Diagrams) method for future knowledge based approaches to the design of HEAs. Compared with other approaches for designing HEAs (e.g. empirical rules, or ab initio based methods), the CALPHAD method provides an optimal balance between efficiency and accuracy. On the other hand, most multicomponent systems are not fully covered by the available CALPHAD databases. Instead, current CALPHAD simulations of multicomponent systems are based on the extrapolation from binary, ternary, and, (perhaps) quaternary systems. Hence, the accuracy of the corresponding predictions yielded by using a CALPHAD approach needs to be critically evaluated.

The objective of this study is to experimentally and theoretically investigate the phase stability of non-equiatomic FexMn62ÿxNi30Co6Cr2 based high entropy alloys, where x ranges from 22 to 42 at.%. Another aim is to systematically and critically assess the predictive capability of the CALPHAD approach for such high entropy alloy systems. We find that the CALPHAD simulations provide a very consistent assessment of phase stability yielding good agreement with experimental observations. These include the equilibrium phase formation at high temperatures, the constituent phases after non-equilibrium solidification processes, unfavorable segregation profiles inherited from solidification together with the associated nucleation and growth of low temperature phases, and undesired martensitic transformation effects. Encouraged by these consistent theoretical and experimental results, we extend our simulations to other alloy systems with equiatomic compositions reported in the literature. Using these other equiatomic model systems we demonstrate how systematic CALPHAD simulations can improve and accelerate the design of multicomponent alloy systems.

Acta Materialia 98 (2015) 288-296

Phase stability of non-equiatomic CoCrFeMnNi high entropy alloys

Duancheng Ma, Mengji Yao, K.G. Pradeep, Cemal C. Tasan, Hauke Springer, Dierk Raabe

Acta Mater 98 (2015) 288 Non-Equiatomic [...]

PDF-Dokument [636.7 KB]

Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one

Acta Materialia vol 100 (2015) pages 90-97

Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one

Duancheng Ma, Blazej Grabowski, Fritz Körmann, Jörg Neugebauer, Dierk Raabe

Acta Materialia 100 (2015) 90 Ab initio [...]

PDF-Dokument [528.5 KB]

High entropy alloy (HEA) refers to a multi-component (5 or more) single-phase solid-solution alloy in or near an equi-atomic composition [1–3]. The basic idea behind HEAs is an

exploration of phase diagrams which are not confined to regions of a single major base element as in conventional alloy design. The aim of the new concept is a development of new alloy

systems with novel mechanical and functional properties [1–4]. The term ‘‘high entropy” refers to the high configurational entropy which is deemed to be responsible for the stability

of the single solid solution phase over competing intermetallic and elemental phases

[1,2]. The configurational entropy is however only one out of various contributions to the Gibbs free energy and it is the latter that

determines phase stabilities. It is therefore of crucial importance to also investigate the role of (1) the formation enthalpy and (2) other entropy contributions.

The role of the formation enthalpy has been recently addressed by [5]. The authors showed that among various multi-component alloys with equal ideal configurational entropy only one was

sufficiently stabilized to form a single-phase solid-solution. In all other multi-component alloys studied in Ref. [5], the formation enthalpy was dominant over the configurational

entropy resulting in the

formation of intermetallic phases. The impact of entropy contributions other than the configurational one on the phase stability of HEAs has so far only scarcely been addressed. Rather,

with reference to the first core effect, it has been implicitly assumed that entropic contributions related to atomic vibrations, electronic and magnetic excitations are negligible in

determining phase

stabilities in HEAs.

In the present paper we employ ab initio based simulations to investigate the validity of the latter assumption for the prototype HEA CoCrFeMnNi [6–10]. In particular, we study the phase

stability between hcp, fcc, and bcc structures by calculating the free energies of the respective crystal structures at T = 0 K as well as at finite temperatures, including a detailed

analysis of the balance between the different entropy contributions (vibrational, electronic, magnetic

as well as configurational).

More specific we investigate the thermodynamic properties of the prototype equi-atomic high entropy alloy (HEA) CoCrFeMnNi by using finite-temperature ab initio methods. All relevant free energy contributions are considered for the hcp, fcc, and bcc structures, including electronic, vibrational, and magnetic excitations. We predict the paramagnetic fcc phase to be most stable above room temperature in agreement with experiment. The corresponding thermal expansion and bulk modulus agree likewise well with experimental measurements. A careful analysis of the underlying entropy contributions allows us to identify that the originally postulated dominance of the configurational entropy is questionable. We show that vibrational, electronic, and magnetic entropy contributions must be considered on an equal footing to reliably predict phase stabilities in HEA systems.

A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility

M.J. Yao, K.G. Pradeep et al.: Scripta Materialia 72–73 (2014) 5-8

A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility

2014_Article_Scripta_FeMnNiCoCr.pdf

PDF-Dokument [1.4 MB]

High-entropy alloys (HEAs) are multi-component systems based on the novel alloy design

strategy of configurational entropy (CE) maximization. This strategy aims at a reduction of Gibbs free energy by the increase in CE, to design phases with simple

structures, rather than brittle ordered intermetallics typical of many multi-component systems.As a result of multiple alloy components creating strong lattice distortion,

HEAs are promising candidates for many potential applications with expectedly high solid-solution strengthening and excellent resistance to high-temperature softening.

To this end, HEAs were initially defined to consist of at least five principal elements of concentrations between 5 and 35 at.%, in order to maximize the CE and facilitate the

formation of solid solutions. Recent reports, however, have questioned such a dominant role of the CE independent of the mixing enthalpy, and have stressed that the Gibbs free energy

is decisive for phase formation, even in cases of increased CE. While the role of the CE is still under debate, it is interesting to note that the majority of the introduced HEAs still

follow the original concentration design criterion, i.e. near-equiatomic ratios, while non-equiatomic

HEAs have rarely been investigated. On the other hand, although many HEAs have been designed and studied recently, their tensile test performance was rarely documented. Instead,

mechanical properties were often characterized in terms of compression tests or hardness. In fact, with the exception of a very recent work reporting good ductility, most of the

HEAs designed to date have very limited tensile ductility, often not exceeding a few percent of strain prior

to fracture. In this context it appears essential to better understand whether the limited ductility is arising from processing issues (e.g. due to consolidation problems

during mechanical alloying), characterization issues (e.g. due to undetected intermetallic phase formation) or due to any unknown intrinsic limitations of such

multi-component systems with strong solid-solution hardening.

This study aims at improving our understanding on these points, namely: (i) the role ofCE in the phase formation, and (ii) the true tensile behavior of HEAs. For this purpose we

introduce a novel Fe40Mn27Ni26Co5Cr2 (at.%) HEA, which offers several advantages in the context mentioned above:

More specific, here a non-equiatomic FeMnNiCoCr alloy is introduced and characterized at multiple scales employing various characterization techniques (e.g. atom probe tomography, electron channeling contrast imaging, electron backscatter diffraction, etc.) to elucidate (i) the role of configurational entropy and (ii) the intrinsic tensile ductility of high-entropy alloys. Results reveal that the new material is a true high-entropy alloy with a stable random solid solution despite its comparably low configurational entropy, and that it has excellent tensile ductility irrespective of the substantial lattice distortion.

A twinning-induced plasticity high entropy alloy

Acta Materialia 94 (2015) 124-133: Design of a twinning-induced plasticity high entropy alloy, Y. Deng, C.C. Tasan, K.G. Pradeep,H. Springer, A. Kostka, D. Raabe

Acta Materialia 94 (2015) 124 Twinning I[...]

PDF-Dokument [1.4 MB]

During the past years, the high entropy alloy (HEA) concept has attracted extensive research attention owing to its promising mechanical properties. This new

alloy design strategy aims at the maximization of the entropy of mixing with the purpose of producing massive solid solution, single phase microstructures. The heavy lattice distortion and

the sluggish diffusion introduced as a result of

mixing multiple components in equal proportions are proposed to jointly contribute to high thermal stability and good mechanical properties (which can be greatly adjusted by a potential

cocktail (multi-phase) effect). In order to

achieve that, the initially proposed design criterion was based on the presence of at least five elements in equiatomic or near equiatomic concentrations. However, among various HEAs

that have been designed according to these criteria (e.g. AlCoCrCuFeNi, AlCrFeMnNi, FeMnNiCoCr), most show multi-phase microstruc-

tures and exhibit varied properties (wear resistance, corrosion resistance, high strength, etc). While multiphase HEAs promote fundamental investigations of phase separation in massive

solid solutions, and enlarge the achievable property

(and hence application) spectrum, they essentially do not provide proof-of-principle observations for the original concept described above. The only alloy system that develops a single fcc

solid solution upon conventional casting is

FeMnNiCoCr system. Hence, this most successful example of the HEA concept has been extensively investigated focusing on different aspects such as vacancy motion, optimization of

mechanical properties by thermomechanical treatments, texture evolution and deformation mechanisms. However, setting the striking stability of the single fcc solid solution aside, the

equiatomic FeMnNiCoCr alloy

shows significant similarities in terms of mechanical behavior to conventional fcc steels with low stacking fault energy. In fact, under quasi-static uniaxial tensile loading, the room

temperature mechanical performance of FeMnNiCoCr HEA is well-comparable to those of simple binary Fe–Mn alloys. On the other hand, Gludovatz et al. recently reported that the

equiatomic FeMnNiCoCr alloy out-performs all conventional alloys under cryogenic conditions. The fracture toughness values measured by compact tension test at cryogenic temperatures

down to 77 k were found to exceed 200 MPa m^1/2 at crack initiation and 300 MPa m^1/2 for stable crack growth. The underlying deformation mechanism that determines these excellent

properties is nanotwinning, which was however

not observed at ambient temperatures. Recently, we have shown through non-equiatomic HEA design, that the maximization of configurational entropy is not a strict criterion that

determines massive solid solution formation, and that it can form over a wide range of compositions. The reason for this is that the shape of the entropy curve as a function of

chemical composition is for most transition metal mixtures very flat so that even larger compositional deviations from the equi-atomic alloying rule yield the same entropy as the an

equi-atomic mixing. This thermodynamic relaxation of the originally quite strict high entropy alloy rule opens a wide alloying window for realizing true single phase states and

corresponding property tuning. Therefore, composition variations can be explored to optimize the stacking fault energy and to transfer the excellent nanotwinning induced cryogenic mechanical

behavior to room temperature. We demonstrate this approach via the design of a lean (i.e. in terms of Co, Cr and especially Ni content with respect to the equiatomic

five-component alloy) twinning-induced plasticity high entropy alloy (TWIP-HEA), Fe40Mn40Co10Cr10 with excellent room temperature mechanical properties that are comparable to those of

advanced TWIP steels.

More specific in this paper we introduce a liquid metallurgy synthesized, non-equiatomic Fe40Mn40Co10Cr10 high entropy alloy that is designed to undergo

mechanically-induced twinning upon deformation at room temperature. Microstructure characterization, carried out using SEM, TEM and APT shows a homogeneous fcc structured single phase solid solution in the as-cast, hot-rolled and homogenized states. Investigations of the deformation substructures at specific strain levels with electron channeling contrast imaging (ECCI) combined with EBSD reveal a clear change in the deformation mechanisms of the designed alloy starting from dislocation slip to twinning as a function of strain. Such twinning induced plasticity has only been observed under cryogenic conditions in the equiatomic FeMnNiCoCr high entropy alloy. Thus, despite the decreased contribution of solid solution strengthening, the tensile properties of the introduced lean alloy at room temperature are found to be comparable to that of the well-studied five component FeMnNiCoCr system.

Atomic-scale compositional characterization of a high-entropy alloy using atom probe tomography

Acta Materialia 61 (2013) 4696-4706

K.G. Pradeep, N. Wanderka, P. Choi, J. Banhart, B.S. Murty, D. Raabe

Atomic-scale compositional characterization of a nanocrystalline AlCrCuFeNiZn high-entropy alloy using atom probe tomography

Acta Materialia 61 (2013) 4696–4706 High[...]

PDF-Dokument [719.0 KB]

We have studied a nanocrystalline AlCrCuFeNiZn high-entropy alloy synthesized by ball milling followed by hot compaction at 600 C for 15 min at 650 MPa.

X-ray diffraction reveals that the mechanically alloyed powder consists of a solid-solution body-centered cubic (bcc) matrix

containing 12 vol.% face-centered cubic (fcc) phase. After hot compaction, it consists of 60 vol.% bcc and 40 vol.% fcc. Composition analysis by atom probe tomography (APT) shows that the material is not a homogeneous fcc–bcc solid solution but instead a composite of bcc structured Ni–Al-, Cr–Fe- and

Fe–Cr-based regions and of fcc Cu–Zn-based regions. The Cu–Zn-rich phase has 30 at.% Zn a-brass composition. It segregates

predominantly along grain boundaries thereby stabilizing the nanocrystalline microstructure and preventing grain growth. The

Cr- and Fe-rich bcc regions were presumably formed by spinodal decomposition of a Cr–Fe phase that was inherited from the hot compacted state. The Ni–Al phase remains stable even after hot

compaction and forms the dominant bcc matrix phase. The crystallite sizes are in the range of 20–30 nm as determined by transmission electron microscopy. The hot compacted

alloy exhibited very high hardness of 870 ± 10 HV. The results reveal that phase decomposition rather than homogeneous mixing is prevalent

in this alloy. Hence, our current observations fail to justify the present high-entropy alloy design concept. Therefore, a strategy guided more by structure and thermodynamics for

designing high-entropy alloys is encouraged as a pathway towards exploiting the solid-solution and stability idea inherent in this concept.

Phase Stability, Deformation Mechanisms, and Mechanical Properties of the CoCrFeMnNi High-Entropy Alloy System

JOM, Vol. 66, No. 10, 2014:

High entropy alloys JOM 2014 Tasan et al[...]

PDF-Dokument [2.4 MB]

The proposal of configurational entropy maximization to produce massive

solid-solution (SS)-strengthened, single-phase high-entropy alloy (HEA) systems has gained much scientific interest. Although most of this interest

focuses on the basic role of configurational entropy in solid solution formability, setting future research directions also requires the overall property benefits of

massive solid solution strengthening to be carefully investigated. To this end, taking the most promising CoCrFeMnNi HEA system as the starting point, we

investigate solid solution formability, deformation mechanisms, and the achievable mechanical property ranges of different compositions and

microstructural states. A comparative assessment of the results with respect to room temperature behavior of binary Fe-Mn alloys reveals only limited benefits of massive

solid solution formation. Nevertheless, the results also clarify that the compositional requirements in this alloy system to stabilize the

face-centered cubic (fcc) solid solution are sufficiently relaxed to allow considering nonequiatomic compositions and exploring improved strength–ductility

combinations at reduced alloying costs.

What can we learn from massive solid solution steels on optimal HEA design ?

Below I list some 'blueprint' papers regarding strain hardening design in massive solid solution steels with FCC lattice structure. We try to systematically transfer these FCC strain hardening mechanisms to HEA, i.e. for example through an compositional alloy adjustment with the aim of designing an ideal value for the stacking fault energy. This strategy allows us to create high entropy alloys with face centered cubic structure with reduced stacking fault energies which enables activation of either twinning induced plasticity or transformation induced plasticity. Some of the governing papers where we learned how to do this for the case of massive solid solution steels with face centered cubic lattice structure are given below:

Acta Materialia 60 (2012) 5791-5802

2012-Acta FeMnAlC-multi-strain-hardening[...]

PDF-Dokument [1.8 MB]

We investigate the kinetics of the deformation structure evolution and its contribution to the strain hardening of a Fe–30.5Mn–2.1Al–1.2C (wt.%) steel during tensile deformation by means of

transmission electron microscopy and electron channeling contrast imaging combined with electron backscatter diffraction. The alloy exhibits a superior combination of strength and ductility

(ultimate tensile strength of 1.6 GPa and elongation to failure of 55%) due to the multiple-stage strain hardening. We explain this behavior in terms of dislocation substructure refinement

and subsequent activation of deformation twinning. The early hardening stage is fully determined by the size of the dislocation substructure, namely, Taylor lattices, cell blocks and dislocation

cells. The high carbon content in solid solution has a pronounced effect on the evolving dislocation substructure. We attribute this effect to the reduction of the dislocation cross-slip

frequency by solute carbon. With increasing applied stress, the cross-slip frequency increases. This results in a gradual transition

from planar (Taylor lattices) to wavy (cells, cell blocks) dislocation configurations. The size of such dislocation substructures scales inversely with the applied resolved stress. We do not

observe the so-called microband-induced plasticity effect. In the present case, due to texture effects, microbanding is not favored during tensile deformation and, hence, has no effect on strain

hardening.

Acta Materialia 61 (2013) 494-510

Acta Materialia 61 (2013) 494 Strain har[...]

PDF-Dokument [1.8 MB]

We present a multiscale dislocation density-based constitutive model for the strain-hardening behavior in twinning-induced plasticity (TWIP) steels. The approach is a physics-based strain

rate- and temperature-sensitive model which reflects microstructural investigations of twins and dislocation structures in TWIP steels. One distinct advantage of the approach is that the model

parameters, some of which are derived by ab initio predictions, are physics-based and known within an order of magnitude. This allows more complex microstructural

information to be included in the model without losing the ability to identify reasonable initial values and bounds for all parameters. Dislocation cells, grain size and twin volume fraction

evolution are included. Particular attention is placed on the mechanism by which new deformation twins are nucleated, and a new formulation for the critical twinning stress is presented. Various

temperatures were included in the parameter optimization process. Dissipative heating is also considered. The use of physically justified parameters enables the identification of a

universal parameter set for the example of an Fe–22Mn–0.6C TWIP steel.

Materials Science and Engineering A 527 (2010) 3552

MSE-A_2010_TWIP.pdf

PDF-Dokument [2.1 MB]

We investigate the effect of grain size and grain orientation on deformation twinning in a Fe–22 wt.% Mn–0.6 wt.% C TWIP steel using microstructure observations by electron channeling

contrast imaging (ECCI) and electron backscatter diffraction (EBSD). Samples with average grain sizes of 3m and 50m

were deformed in tension at room temperature to different strains. The onset of twinning concurs in both materials with yielding which leads us to propose a Hall–Petch-type relation for the

twinning stress using the same Hall–Petch constant for twinning as that for glide. The influence of grain orientation

on the twinning stress is more complicated. At low strain, a strong influence of grain orientation on deformation twinning is observed which fully complies with Schmid’s law under the assumption

that slip and twinning have equal critical resolved shear stresses. Deformation twinning occurs in grains oriented

close to 111//tensile axis directions where the twinning stress is larger than the slip stress. At high strains (0.3 logarithmic strain), a strong deviation from Schmid’s law is observed.

Deformation twins are now also observed in grains unfavourably oriented for twinning according to Schmid’s law. We explain

this deviation in terms of local grain-scale stress variations. The local stress state controlling deformation twinning is modified by local stress concentrations at grain boundaries

originating, for instance, from incoming bundles of deformation twins in neighboring grains.

steel research int. 86 (2015) No. 9999

steel research int. 86 (2015) Raabe High[...]

PDF-Dokument [802.0 KB]

Inspired by high-entropy alloys, we study the design of steels that are based on high configurational entropy for stabilizing a single-phase solid solution matrix. The focus is placed on

the system Fe–Mn–Al–Si–C but we also present trends in the alloy system Fe–Mn–Al–C. Unlike in conventional high-entropy alloys, where five or more equiatomically proportioned components are

used, we exploit the flat configurational entropy plateau in transition metal mixtures, stabilizing solid solutions also for lean, non–equiatomic compositions. This renders the high-entropy

alloying concept, where none of the elements prevails, into a class of Fe-based materials which we refer to as high-entropy steels. A point that has received little attention in

high-entropy alloys is the use of interstitial elements. Here, we address the role of C in face-centered cubic solid solution phases.

High-entropy steels reveal excellent mechanical properties, namely, very high ductility and toughness; excellent high rate and low-temperature ductility; high strength of up to 1 GPa; up to

17% reduced mass density; and very high strain hardening. The microstructure stability can be tuned by adjusting the stacking fault energy. This enables to exploit deformation effects such

as the TRIP, TWIP, or precipitation determined mechanisms.