Some Basic Metallurgical and Engineering Considerations of Aircraft Aluminum Alloys

The evolution of aluminum alloys in aerospace engineering reflects a continuous optimization of the intrinsic trade-off between strength, corrosion and damage tolerance. Early designs, based on static tensile properties and elastic modulus, yielded to a modern paradigm rooted in Fracture Mechanics and Durability and Damage Tolerance (DaDT) principles.

I. Foundational Metallurgy and Early Failures

The foundation of high-strength aircraft aluminum rests on Dr. Alfred Wilm’s discovery of age-hardening in Al-Cu alloys (Duralumin). This process involves:

- Solution Heat Treatment (SHT): Dissolving solute atoms into the α-Al matrix above the solvus.

- Quenching: Rapidly locking the solute atoms and vacancies in a supersaturated solid solution.

- Ageing: Allowing precipitation strengthening via the nucleation and growth of coherent, semi-coherent, and finally incoherent precipitate phases, which interact with dislocations to increase yield strength.

The earliest structural failures, such as the catastrophic Stress-Corrosion Cracking (SCC) observed in the Al-Cu-Mg alloy of the USS Shenandoah in 1925, immediately highlighted the critical importance of corrosion mitigation, leading to the development of composite sheet materials, i.e. high-strength core clads with a pure (1xxx) aluminum layer on the outside, providing cathodic protection to the core alloy.

II. The Damage Tolerance Paradigm

The structural failures of the de Havilland Comet (1953-54) due to metal fatigue and the subsequent Aloha Airlines incident (1988), which exposed significant fatigue cracks followed by a fracture toughness failure, cemented the current DaDT design philosophy. Structural life is now assessed across three key phases:

- Fatigue Initiation: Primarily occurring at microstructural stress concentrators, including non-metallic inclusions, residual porosity (due to hydrogen or shrinkage), and coarse constituent particles (typically Fe- and Si-bearing intermetallics).

- Fatigue Crack Growth (FCG): The rate at which a crack propagates under cyclic stress (governed by the stress intensity factor range, ΔK). FCG is a paramount property for modern aerospace alloys.

- Final Fracture: Occurs when the crack reaches a critical size. This event is governed by the material's fracture toughness, which is inversely related to yield strength.

III. Microstructural Engineering for Performance

Material development since the 1960s has focused on optimizing the microstructure to enhance toughness and fatigue resistance:

- Purity Control: Alloys such as 7475 (high-purity 7075), 2124, 2524, and 2624 (high-purity 2024 variants) were developed by drastically reducing Fe and Si impurity levels. This minimizes the volume fraction and size of coarse intermetallic constituent phases that readily fracture under stress, initiate microvoids, and link cracks, thereby governing the dimple size and reducing toughness.

- Grain Structure: Controlling the texture and grain structure of wrought products is critical. Unrecrystallized microstructures are favored, particularly in extrusions and plate, as they typically offer the optimal combination of strength and toughness anisotropy.

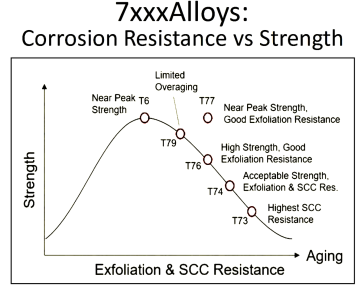

- Corrosion/Strength Trade-off (7xxx Alloys): The relationship between strength and corrosion resistance is managed via post-solution heat treatment aging (T-tempers):

- T6 Temper: Achieves near-peak strength but suffers from poor corrosion resistance.

- T7x Tempers (T74, T76, T77): Involve over-aging to a sub-peak strength regime. This drives coarsening of precipitates along grain boundaries, fundamentally changing the anodic/cathodic relationship and mitigating the susceptible path for intergranular corrosion and SCC, achieving the Highest SCC Resistance (e.g., T73) or a superior balance of Near Peak Strength and Good Exfoliation Resistance (e.g., T77).

IV. Advanced Alloys and Manufacturing Economics

Modern alloy development focuses on specific property enhancements:

- Al-Cu-Li Alloys (e.g., 2195, 2050): Provide an inherent advantage in specific strength (strength/density) and superior Fatigue Crack Growth (FCG) resistance.

- 7085-T7x: Specifically engineered for very thick-section applications (e.g., wing fittings) where its lower quench sensitivity ensures adequate strength uniformity across the cross-section.

Manufacturing efficiency is a major economic driver for aircraft builders, particularly for single-aisle jets. The process of machining large structural components (ribs, spars, stringers) from plate or extrusions often results in high material wastage, with "Buy/Fly" ratios reaching 10:1 to 20:1. This high cost of machining and scrap, coupled with the rising cost of advanced alloys, has provided a strong economic incentive for the aerospace industry to adopt carbon fiber composites for long-range, twin-aisle aircraft, especially where the weight savings justify the material cost. However, aluminum alloys, augmented by advanced joining techniques like Friction Stir Welding (FSW), are likely to remain dominant in the single-aisle jet market due to cost efficiency.

Specific Aluminium Alloys for Aerospace Applications

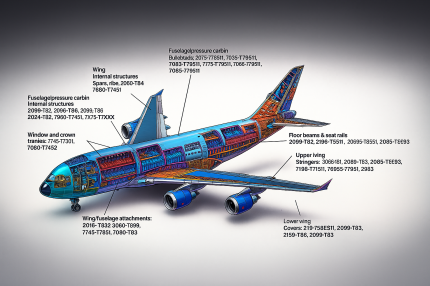

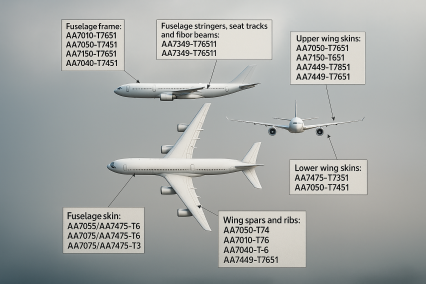

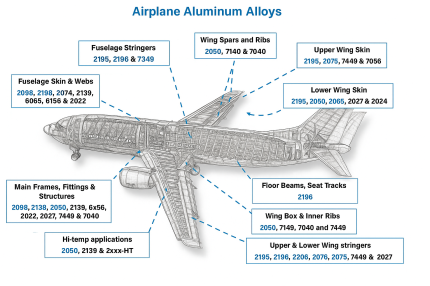

Aluminium alloys cover in most planes up to 80% of the material that is used. Its low mass density, high specific strength and good elastic stiffness, excellent ductility and high corrosion resistance, modest price and very good manufacturability (extrusion, roling, bending, welding, repairability, additive manfacturing) render aluminium alloys the most important aerospace materials. Therefore, aluminium alloys are the material of choice in multiple aerospace structural applications, e.g. the panels used for the entire outer fuselage, upper and lower wing skins, and wing stringers, etc.

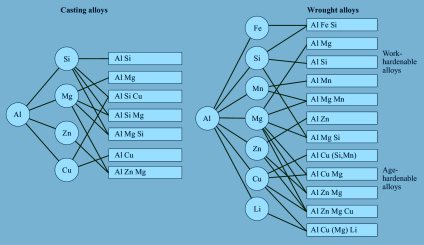

The most widely consumed aluminium alloys in aerospace industries are the Al-Cu alloys (2xxx series), Al-Zn alloys (7xxx series) and Al-Li alloys.

2xxx series alloys are mainly used where high damage tolerance and fracture toughness are essential features. AA2024 is one of the most commonly used Al alloys in fuselage structures due to its excellent damage tolerance at T3 condition. Yet, its limited yield strength ranges (345 MPa) and fracture toughness ( 37 MPa·m0.5) restrict its application and it has been replaced by AA2524-T3 in the fabrication of many aircraft such in the as Boeing 777 aircraft, which has 15% to 20% improved fracture toughness resulting in 30% to 40% weight reduction.

AA2224 and AA2324 provide enhanced strength and are used in the lower wing skin. AA2026 is considered an excellent replacement of AA2024 because of its better damage tolerance and fatigue resistance, as well as higher strength.

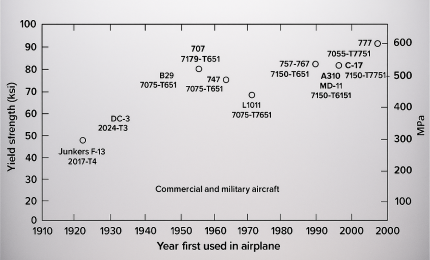

The advanced AA7xxx series alloys are widely applied in the aerospace components where high strength is the driving requirement, including upper wing skins, horizontal and vertical stabilizers and wing stringers. AA7075-T6 has been used as an airframe material since the 1940s because of its relatively high specific strength (204 kN·m/kg) and low price. However, the susceptibility to corrosion of this alloy reduced the life of the airframe components, which has led to its replacement by new AA7xxx series alloys in many applications. For example, AA7475 has higher yield strength (490 MPa) and a better combination of corrosion resistance and fracture toughness ( 33 MPa·m0.5), which makes it an ideal replacement for AA7075.

Another high performance alloy AA7050 is used in fuselage frames and bulkheads as a form of thick plate (the best thickness ranges from 76 mm to 152 mm), and the sheet materials are used to fabricate wing skins.

The yield stress of AA7055-T7751 can reach 620 MPa with high fracture toughness and corrosion resistance. The application of this alloy in components in the Boeing 777 reduced the airplane weight by 635 kg.

Al-Li alloys are advanced heat treatable lightweight aluminium alloys that can decrease the density by up to 10% by including 1% to 3% of lithium. The introduction of lithium also enhances the elastic modulus of the alloys by 6% for each percentage of lithium added.

Al-Li alloys are lighter and stiffer than other aerospace aluminium alloys, such as AA2090, AA2091, AA8090 and AA8091 (1.9%–2.7% lithium) and are about 10% lighter and 25% stiffer than AA2xxx and AA7xxx series alloys. AA2199 alloy sheet and plate have already been used in fuselage and lower wing components (e.g. AA2199 sheets are used in fuselage skins providing a structure lighter, better fatigue toughness, higher strength (400 MPa), better corrosion stress and exfoliation corrosion resistance than those made of AA2024). Extrusions of AA2099 could be an excellent replacement for conventional aerospace aluminium alloys for application to internal fuselage structures and lower wing stringers. AA2050 could replace conventional Al alloys where medium or high strength and damage tolerance are required to offer better lightweight performance. AA2198 could replace AA2024 and AA2524 for high damage tolerance applications (AA2198 can absorb 2 to 3 times of energy to fracture than AA2024). AA2060 and AA2055 alloys exhibit enhanced strength, fracture toughness and thermal stability that could replace the conventional aerospace aluminium alloys in fuselage and wing components applications. Application of AA2060-T8 reduced the structural mass by 14% in wing stringers and upper wing skin application, compared with that of the conventional material AA2024-T351. More details are in : L. Zhu, N. Li, P.R.N. Childs , Propulsion andPowerResearch2018;7(2):103–119