Superalloys

Further typcial application fields are in heat exchangers, components for chemical reaction vessels, equipment for heat treatment and oil and gas-drilling

products.

Due to their ability to withstand deformation at high temperatures, they are

not veryductile and thus challenging to process.

To achieve the properties required to be classified as a superalloy, these materials usually contain nickel or cobalt as a matrix metal and higher fractions of various refractory alloying

elements.

Some examples of superalloy families are:

Cobalt – Based: Haynes, Hiperco, Stellite

Iron – Based: Astroloy

Nickel - Based: Hastelloy, Rene, Inconel, Waspaloy, Monel

Scripta Materialia 157 (2018) 62–66

1-s2.0-S1359646218304718-main.pdf

PDF-Dokument [1.9 MB]

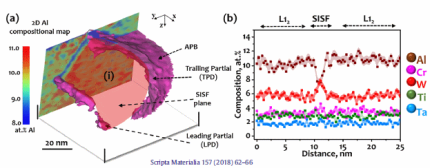

We report on the full three-dimensional compositional partitioning among the features of a planar imperfection comprising a superlattice intrinsic stacking fault (SISF) with its leading and

trailing partials, as well as the antiphase boundary (APB) in the wake of the trailing partial formed in the L12-ordered γ′ phase of a CoNibased single crystal superalloy. The partial

dislocations and the APB are found to be Cr/Co rich relative to the surrounding γ′ and richer inW/Ta/Ti compared to the γ matrix phase. Solute diffusionmechanisms are derived from

the compositional gradients in the vicinity of the imperfection

2018, Metallurgical and Materials Transactions A

METAL MATER TRAN oxidized carbides in su[...]

PDF-Dokument [6.5 MB]

Oxidized MC carbides which act as main crack initiation sites in a polycrystalline superalloy under thermal-mechanical fatigue (TMF) conditions at 850° C were studied. Microstructural observations in the TMF tested specimens were compared to findings from bulk samples exposed isothermally in air at 850° C for 30 hours in the absence of any external applied load. Carbides were found to oxidize rapidly after exposure at 850° C for 30 hours resulting in surface eruptions corresponding to oxidation products, from where micro-cracks initiated. Plastic deformation due to volume expansion of the often porous oxidized carbides led to high dislocation densities in the adjacent matrix as revealed by controlled electron channeling contrast imaging. The high dislocation density facilitated the dissolution kinetics of γ′ precipitates by segregation and diffusion of chromium and cobalt along the dislocations via pipe diffusion, resulting in the formation of soft recrystallized grains

How to overcome hot-cracking in additively-manufactured superalloys?

There are still debates regarding the mechanisms that lead to hot cracking in parts build by additive manufacturing (AM) of non-weldable nickel-based superalloys. This lack of in-depth

understanding of the root causes of hot cracking is an impediment to designing engineering parts for safety-critical ap-

plications. Here, we deploy a near-atomic-scale approach to investigate the details of the compositional decoration of grain boundaries in the coarse-grained, columnar microstructure in parts

built from a non-weldable nickel-based superalloy by selective electron-beam melting. The progressive enrichment in Cr,

Mo and B at grain boundaries over the course of the AM-typical successive solidification and remelting events, accompanied by solid-state diffusion, causes grain boundary segregation induced

liquation. This observation is consistent with thermodynamic calculations. We demonstrate that by adjusting build parameters to obtain a fine-grained equiaxed or a columnar microstructure

with grain width smaller than 100 mm enables to avoid cracking, despite strong grain boundary segregation. We find that the spread of critical solutes to a higher total interfacial area,

combined with lower thermal stresses, helps to suppress interfacial liquation.

Acta Mater 2019 Atomic-scale grain bound[...]

PDF-Dokument [5.9 MB]

Why do Nickel-base superalloys crack during additive manufacturing?

In this project a non weldable nickel-based superalloy was fabricated by powder bed-based selective electron beam melting (S-EBM). The as-built samples exhibit a heterogeneous microstructure

along the build direction. A gradient of columnar grain size as well as a significant gradient in the g0 precipitate size were found along the build direction. Microstructural defects such

as gas porosity inherited from the powders, shrinkage pores and cracks inherited from the S-EBM process were identified. The origins of those defects are discussed with a particular emphasis on

crack formation. Cracks were consistently found to

propagate intergranular and the effect of crystallographic misorientation on the cracking behavior was investigated. A clear correlation was identified between cracks and high angle grain

boundaries (HAGB). The cracks were classified as hot cracks based on the observation of the fracture surface of micro-tensile

specimens machined from as-built S-EBM samples. The conditions required to trigger hot cracking, namely, presence of a liquid film during the last stage of solidification and thermal stresses

are discussed within the framework of additive manufacturing. Understanding the cracking mechanism enables to provide guidelines to obtain crack-free specimens of non-weldable Ni-based

superalloys produced by S-EBM.

Acta Materialia 142 (2018) 82-94

Acta Mater 2017 Hot cracking Ni-based su[...]

PDF-Dokument [6.5 MB]

What is the role and influence of Ruthenium in Nickel-base superalloys?

Acta Materialia 95 (2015) 274-283

Effect of ruthenium on the precipitation of topologically close packed phases in Ni-based superalloys of 3rd and 4th generation

K. Matuszewski, R. Rettig, H. Matysiak, Z. Peng, I. Povstugar, P. Choi, J. Müller, D. Raabe, E. Spiecker, K.J. Kurzydłowski, R.F. Singer

Acta Materialia 95 (2015) 274 Ni base su[...]

PDF-Dokument [1.6 MB]

The precipitation of topologically close packed (TCP) phases is detrimental for the high temperature strength of high refractory Ni-based superalloys. The beneficial influence of Ru with

respect to this so called instability is nowadays well accepted. In the present paper the precipitation of topologically close

packed (TCP) phases is studied quantitatively in two experimental alloys (one Ru-free and one with addition of Ru) to clarify the mechanism of the Ru effect. It is confirmed that the TCP phase

precipitates undergo sequential phase transformation with the tetragonal r-phase precipitating first. Ru retards

the phase transformation and leads to decreased equilibrium volume fraction of TCP phases. The results clearly indicate that Ru decreases the driving force for TCP phase precipitation.

Investigations of crystallography and chemistry of the TCP/matrix interface point to an additional effect by increase of misfit

strain energy.

What is the role Rhenium in Nickel-base superalloys?

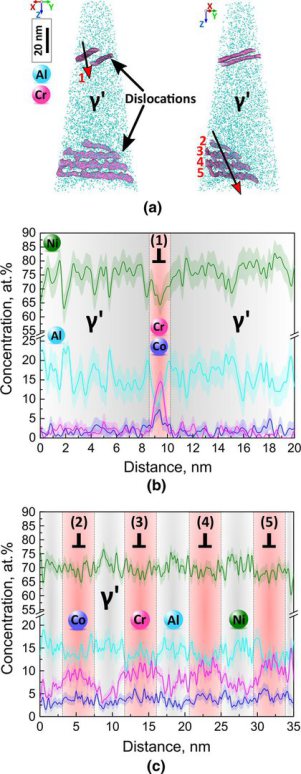

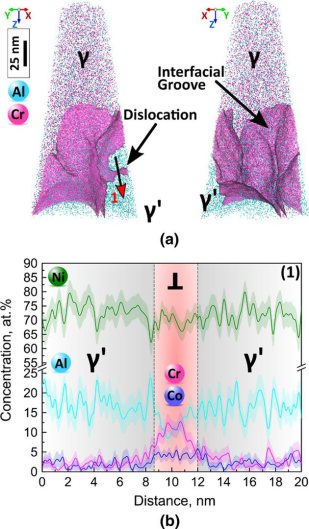

Correlative atom probe tomography and electron mocroscopy analysis shows that Re enriches to partial dislocations and imposes a drag effect on dislocation movement, thus reducing the creep strain rate and thereby improving creep properties.

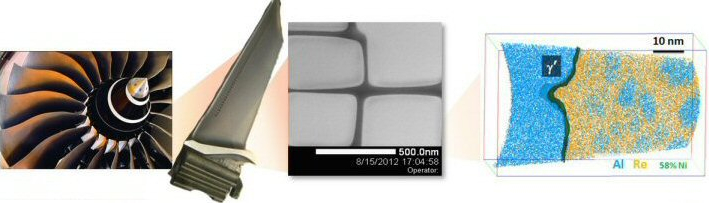

Single crystal Ni-based superalloys serve as essential material in gas turbines in aero engines and power plants due to their excellent high temperature creep, fatigue and oxidation resistance.

A unique turning point was the addition of only 3 wt.% Re in the second generation of single crystal Ni-based superalloys which almost doubled the creep lifetime.

Despite the significance of this improvement, the mechanisms underlying the so-called “Re effect” have remained controversial. Here, we provide direct evidence of Re enrichment

to crystalline defects formed during creep deformation, using combined transmission electron microscopy, atom probe tomography and phase field modelling.

By using Correlative atom probe tomography and electron mocroscopy analysis we have found that Re

enriches at partial dislocations and imposes a drag effect on dislocation movement, thus reducing the overall creep strain rate and thereby improving creep properties. These insights can guide

design of

better superalloys, a quest which is key to reducing CO2 emissions in air-traffic.

What is the background of the Rhenium effect in Nickel-base superalloys?

One of the limiting factors to further enhancing the efficiency and reliability of modern gas turbine engines is the capability of the material used for engine components to sustain an

extremely harsh operation environment, i.e., involving

high temperature gradients (700–1200 °C) and severe stresses (100–800 MPa).

Decades of research and alloy development have resulted in Ni-based superalloys which are characterised by an excellent combination of resistance to high temperature creep, i.e., to plastic

deformation under load at elevated temperature over long periods of time, as well as resistance to high temperature oxidation.

The excellent mechanical properties of Ni-based superalloys originate from their microstructure. Ni-based superalloys have a characteristic two-phase microstructure comprising a disordered γ

matrix phase with a face-centred cubic (FCC) structure and coherently embedded γ′ precipitates that exhibit an FCC-based L12-ordered structure. Ni-based superalloys often contain ten or more

elements in proportions that have been finely tuned to adjust the precipitate shape by misfit engineering, their volume fraction, as well as the overall mechanical properties. Specifically, W

and Re are added to strengthen the γ matrix phase. Al, Ta and Ti are used as stabilisers for γ′ precipitates and the elements Cr and Mo for high temperature corrosion and oxidation

resistance.

The addition of only 3 wt% Re results in a dramatic improvement in the lifetime of the alloy. It significantly lowers the minimum creep rate that can be reached and the creep-to-rupture ratio can

be doubled across different temperature

ranges4–6. Varying the amount of Re, up to ~6 wt%, also in combination with up to ~ 3 wt% Ru, has led to the development of new generations of superalloys with improved creep

properties.

These benefits are unfortunately offset by raising the alloy’s density and cost, as Re and Ru are expensive rare elements present in trace quantities in the earth’s crust. Thus, efforts are being

made to find suitable alternatives to replace part or all of the rare elements in the alloy composition without compromising the alloy’s original properties.

Creep deformation is associated with defects such as dislocations and planar faults, e.g., anti-phase boundaries (APBs), superlattice intrinsic stacking faults (SISFs), superlattice extrinsic

stacking faults (SESF) and complex stacking faults (CSFs) in the γ/γ′ microstructure depending on the deformation conditions.

These planar faults are generated when mobile dislocations in the γ matrix cut through the γ′ precipitates during creep, which is referred to as the γ′ shearing process. Several recent studies

have shown that their local atomic structure is different compared to the surrounding lattice, which is often accompanied by a change in the local composition. Segregation of solutes to

dislocations (resulting in Cottrell atmospheres) and to SFs (Suzuki segregation) have been observed by TEM and atom probe tomography (APT) analysis. As pointed out by Barba et al. and Smith

et al., depending on the type of solute, the properties of superalloys can be affected by solute segregation, e.g., segregation-assisted plasticity, or phase- transformation-induced

strengthening. More specifically, in a single-crystal prototype Ni-based superalloy, Cr and Co enrichment to the APB lowers its energy, facilitating APB-based cutting of γ′14. On the other hand,

if SFs are decorated by Ta and Nb, local phase transformation (γ′ to η phase) is favoured, resulting in reduced precipitate shearing.

Similar segregation engineering has been used for tailoring mechanical properties of Fe-5 at% Mn maraging steels and medium Mn steels.

Despite these efforts, the mechanism(s) underlying the influence of Re on creep deformation remain unclear and a topic of on-going debate, hindering further rational design of new

alloys.

So far, it has been proposed that the Re effect is rooted in three possible sources: (i) solid solution strengthening of the γ phase

due to the large atomic size of Re, (ii) slowest d-shell diffusion element in Ni, slowing down dislocation motion, and (iii) the formation of Re clusters within γ acting as strong obstacles to

dislocation movement.

Of these three, mechanism (iii) is the most controversial. Blavette found evidence for small Re clusters in γ using a one-dimensional atom probe. On the other hand, more recent observations

based on atom probe tomography (APT) show no Re clustering, discounting as such the possible role of Re clustering in improving the creep properties of Ni-based superalloys.

Clearly, further studies are necessary to clarify the possible contribution of Re clustering to the Re effect.

The primary objective of our atom probe analysis is to advance the understanding of Re effect by exploring Re interaction with structural defects, namely dislocations and SFs in γ′, during creep

deformation of single crystal Ni-based superalloys.

To this end, observations from advanced scanning transmission electron microscopy (STEM) and near-atomic resolution APT are combined with phase field (PF) modelling of Re enrichment to dislocations during creep. Experimental observations and modelling imply that Re is dragged by dislocations during creep, contributing to the observed effect of Re on creep behaviour. These results suggest the possibility of alloy design through control of solute partitioning to defects.

Can Atom Probe Tomography data be used for molecular dynamics simulations ?

Atom probe informed simulations of dislocation–precipitate interactions reveal the importance of local interface curvature

A. Prakash, J. Guenole, J. Wang, J. Müller, E. Spiecker, M.J. Mills, I. Povstugar, P. Choi, D. Raabe and E. Bitzek

Acta Materialia 92 (2015) 33 Atom probe [...]

PDF-Dokument [1.8 MB]

The interaction of dislocations with precipitates is an essential strengthening mechanism in metals, as exemplified by the superior high-temperature strength of Ni-base superalloys. Here we use atomistic simulation samples generated from atom probe tomography data of a single crystal superalloy to study the interactions of matrix dislocations with a gamma' precipitate in molecular dynamics simulations. It is shown that the precipitate morphology, in particular its local curvature, and the local chemical composition significantly alter both, the misfit dislocation network which forms at the precipitate interface, and the core structure of the misfit dislocations. Simulated tensile tests reveal the atomic scale details of many experimentally observed dislocation–precipitate interaction mechanisms, which cannot be reproduced by idealized simulation setups with planar interfaces. We thus demonstrate the need to include interface curvature in the study of semicoherent precipitates and introduce as an enabling method atom probe tomography-informed atomistic simulations.

Acta Materialia 78 (2014) 78-85

Acta Mater 2014 Co base superalloy atom [...]

PDF-Dokument [768.8 KB]

Acta Materialia 78 (2014) 78-85:

Ni-base superalloys are nowadays the key engineering materials for high-temperature parts in aircraft engines and stationary turbines for power generation. The excellent creep resistance of these

alloys is provided by a microstructure consisting of coherent cuboidal gamma' (L12) precipitates dispersed in a gamma (face-centered cubic (fcc)) matrix. Since the recent discovery of the ternary

gamma' Co3(Al, W) intermetallic phase by Sato et al. [1], Co-base superalloys with a similar type of microstructure have emerged as a promising alternative to Ni-based alloys, with a potential to

exhibit even better properties. In particular, Co–Al–W based alloys may be less prone to freckling formation [2] and possess higher melting temperatures than Ni-based superalloys [3,4], but they

still exhibit lower creep resistance, mainly due to a lower c0 solvus temperature. In order to compete with their Ni-based counterparts and to achieve commercialization, various properties of gamma'

-strengthened Co-based superalloys must be further understood and optimized. Knowledge-based alloy design is necessary to

optimize the thermal stability, gamma /gamma' lattice misfit, volume fraction of the gamma' phase and thus the mechanical properties at elevated operating temperatures.

Here, elemental partitioning and hardness in Ti- and Ta-containing Co-base superalloys, strengthened by γ′-Co3(Al, W) precipitates, have been studied by local measurements. Using atom probe

tomography, we detect strong partitioning of W (partitioning coefficients from 2.4 to 3.4) and only slight partitioning of Al (partitioning coefficients ⩽1.1) to the γ′-Co3(Al, W) phase. Al

segregates to the γ/γ′ phase boundaries, whereas W is depleted at the γ side of the boundaries after aging at 900 °C and slow air cooling. This kind of Al segregation and W depletion is much less

pronounced when water quenching is applied. As a result, these effects are considered to be absent at high temperatures and therefore should not influence the creep properties. Ti and Ta additions

are found to strongly partition to the γ′ phase and greatly increase the γ′ volume fraction. Our results indicate that the alloying elements Al, W, Ti and Ta all occupy the B sublattice of the A3B

structure (L12 type) and affect the partitioning behavior of each other. Nanoindentation measurements show that Ta also increases the hardness of the γ′ phase, while the hardness of the γ channels

remains nearly constant in all alloys. The change in hardness of the γ′ phase can be ascribed to the substitution of Al and W atoms by Ti and/or Ta.

Acta Materialia 79 (2014) 216-233

Interfacial dislocation motion and interactions in single-crystal superalloys

Acta 2014 dislocations single-crystal su[...]

PDF-Dokument [1.1 MB]

The early stage of high-temperature low-stress creep in single-crystal superalloys is characterized by the rapid development of interfacial dislocation networks. Although interfacial motion and dynamic recovery of these dislocation networks have long been expected to control the subsequent creep behavior, direct observation and hence in-depth understanding of such processes has not been achieved. Incorporating recent developments of discrete dislocation dynamics models, we simulate interfacial dislocation motion in the channel structures of single-crystal superalloys, and investigate how interfacial dislocation motion and dynamic recovery are affected by interfacial dislocation interactions and lattice misfit. Different types of dislocation interactions are considered: self, collinear, coplanar, Lomer junction, glissile junction, and Hirth junction. The simulation results show that strong dynamic recovery occurs due to the short-range reactions of collinear annihilation and Lomer junction formation. The misfit stress is found to induce and accelerate dynamic recovery of interfacial dislocation networks involving self-interaction and Hirth junction formation, but slow down the steady interfacial motion of coplanar and glissile junction forming dislocation networks. The insights gained from these simulations on high-temperature low-stress creep of single-crystal superalloys are also discussed.

Acta Materialia 61 (2013) 3709-3723

discrete-dislocation-modeling-superalloy[...]

PDF-Dokument [2.9 MB]

Creep of single-crystal superalloys is governed by dislocation glide, climb, reactions and annihilation. Discrete three-dimensional (3D) dislocation dynamics (DDD) simulations are used to study the evolution of the dislocation substructure in a gamma/gamma' microstructure of a single-crystal superalloy for different climb rates and loading conditions. A hybrid mobility law for glide and climb is used to map the interactions of dislocations with the gamma' cube precipitates. The focus is on the early stages of creep, where dislocation plasticity is confined to narrow gamma channels. With enhancing climb mobility, the creep strain increases, even if the applied resolved shear stress is below the critical stress required for squeezing dislocations into the gamma channels. The simulated creep microstructure consists of long dislocations and a network near the corners of the gamma' precipitate in the low-stress regime. In the high-stress regime, dislocations squeeze into the gamma channels, where they deposit dislocation segments at the gamma/gamma' interfaces. These observations are in good agreement with experimentally observed dislocation structures that form during high-temperature and low-stress creep.

Darius Tytko, Pyuck-Pa Choi, Jutta Klöwer, Aleksander Kostka, Gerhard Inden, Dierk Raabe

Acta Materialia 60 (2012) 1731-1740

Microstructural evolution of a Ni-based superalloy (617B) at 700°C studied by electron microscopy and atom probe tomography

Acta Materialia 60 (2012) 1731 Ni supera[...]

PDF-Dokument [1.3 MB]

We report on the microstructural evolution of a polycrystalline Ni-based superalloy (Alloy 617B) for power plant applications at a service temperature of 700 C. The formation of secondaryM23C6-carbides close to grain boundaries (GBs) and around primary Ti(C,N) particles is observed upon annealing at 700 C, where gamma' is found to nucleate heterogeneously at M23C6 carbides. Using atom probe tomography, elemental partitioning to the phases and composition profiles across phase and grain boundaries are determined. Enrichments of B at gamma/M23C6 and gamma'/M23C6 interfaces as well as at grain boundaries are detected, while no B enrichment is found at gamma/gamma' interfaces. It is suggested that segregation of B in conjunction with c0 formation stabilizes a network of secondary M23C6 precipitates near GBs and thus increases the creep rupture life of Alloy 617B. Calculations of the equilibrium phase compositions by Thermo-Calc confirm the chemical compositions measured by atom probe tomography.

Alireza B. Parsa, Philip Wollgramm, Hinrich Buck, Christoph Somsen, Aleksander Kostka, Ivan Povstugar, Pyuck-Pa Choi, Dierk Raabe, Antonin Dlouhy, Julian Müuller, Erdmann Spiecker, Kathrin Demtroder, Jüurgen Schreuer, Klaus Neuking and Gunther Eggeler

ADVANCED ENGINEERING MATERIALS 2015, 17, No. 2, page 216

Advanced Scale Bridging Microstructure Analysis of Single Crystal Ni-Base Superalloys

Adv Eng Mat 2015 vol 17 page 216 Scale B[...]

PDF-Dokument [707.6 KB]

Here, we show how conventional and advanced mechanical, chemical, and microstructural methods can be used to characterize cast single crystal Ni-base superalloy (SX) plates across

multiple length scales. Two types of microstructural heterogeneities are important, associated with the cast

microstructure (dendrites (D) and interdendritic (ID) regions – large scale heterogeneity) and with the well-known gamma/gamma' microstructure (small scale heterogeneity). Using electron

probe micro-analysis (EPMA), we can show that elements such as Re, Co, and Cr partition to the dendrites while ID regions

contain more Al, Ta, and Ti. Analytical transmission electron microscopy and atom probe tomography (APT) show that Al, Ta, and Ti partition to the g0 cubes while g channels show higher

concentrations of Co, Cr, Re, and W. We can combine large scale (EPMA) and small-scale analytical methods (APT) to

obtain reasonable estimates for g0 volume fractions in the dendrites and in the ID regions. The chemical and mechanical properties of the SX plates studied in the present work are homogeneous,

when they are determined fromvolumes with dimensions, which are significantly larger than the dendrite spacing. For

the SX plates (140mmx100mmx20mm) studied in the present work this holds for the average chemical composition as well as for elastic behavior and local creep properties.We highlight the

potential of HRTEM and APT to contribute to a better understanding of the role of dislocations during coarsening of the gamma' phase and the effect of cooling rates after high temperature

exposure on the microstructure.

Acta Materialia 109 (2016) 151-161

On the origin of creep dislocations in a Ni-base, single-crystal superalloy: an ECCI, EBSD, and dislocation dynamics-based study

Ram et al Ni base superalloy creep dislc[...]

PDF-Dokument [2.2 MB]

This work investigates the origin of creep dislocations in a Ni-base, single crystal superalloy subject to creep at an intermediate stress and temperature. Employing high angular resolution

electron backscatter diffraction (HR-EBSD), electron channeling contrast imaging under controlled diffraction conditions

(cECCI) and discrete dislocation dynamics (DDD) modelling, it is shown that low-angle boundaries which correspond to dendrite boundaries or their residues after annealing are not the major

sources of creep dislocations. At the onset of creep deformation, they are the only active sources. Creep dislocations are emitted from them and percolate into the dislocation-depleted

crystal. However, the percolation is very slow. As creep deformation proceeds, before the boundary-originated dislocations move further than a few micrometers away from their source

boundary, individual dislocations that are spread throughout the undeformed microstructure become active and emit avalanches of creep dislocations in boundary-free regions, i.e. regions

farther than a few micrometer away from boundaries. Upon their activation, the density of creep dislocations in boundary-free regions soars by two orders of magnitude; and the entire

microstructure becomes deluged with creep dislocations. The total area of boundary-free regions is several times the total area of regions covered by boundary-originated creep

dislocations. Therefore, the main sources of creep dislocations are not low-angle boundaries but individual, isolated dislocations in boundary-free regions.