Teaching, classes, information for students

New classes start summer semester 2022 at RWTH Aachen on Sustainable Materials Science and Green Metallurgy

Synposis for the new class on Sustainable Materials Science and Engineering

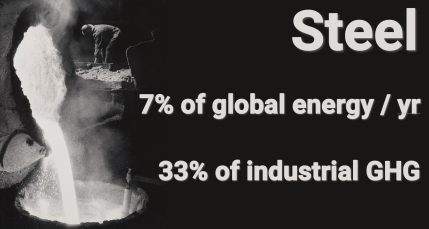

This new course is about the emerging field of sustainable materials science and engineering. The course deals with two aspects of sustainability in this field. The first one is the sustainability of metallurgical processes and the downstream manufacturing chain, which we refer to as direct sustainability effects (e.g. Hydrogen based metallurgical reduction methods). The second one covers sustainability improvement, enabled through the use of advanced materials. We refer to this second branch as, indirect sustainability (e.g. the use of solar cell materials). The motivation for this class is the huge environmental impact of materials and metallurgy. The global production of metals and metallurgical products stands for the gigantic number of about 8% of the total energy consumption on the planet. It is also responsible for about 30% of all industrial CO2 equivalent emissions. These contribute as greenhouse gas to global warming. Therefore, this class tackles the basics materials science aspects of these question, and sheds light on which solutions metallurgy and materials engineering can provide in that context.

A very first introduction can be found here.

An introductory overview paper can be found here.

Title of Course

Sustainable Materials Science and Green Metallurgy (V3, Ü1) (English)

Brief Introduction ot the topic on youtube:

Sustainable Metallurgy and Green Metals - A Green Metallurgy Introduction

Brief Introduction ot the topic in a publication:

Nature: Strategies for improving the sustainability of structural metals

Lecturer: D. Raabe

Start / first class in semester

Friday April 2022

Class room

seminar room, 1st floor,

OR

MET P11

Institut für Metallkunde und Metallphysik (IMM),

RWTH Aachen, Kopernikusstrasse 14, Aachen, Germany

Class Contents

This is an introductory class about sustainable metals and metallurgy, a field that is also referred to as green

metallurgy.

Engineering materials and particularly metallic alloys have enabled technological progress over millenia.

Metallic materials have a historic and enduring importance in our society. They have paved the path of human civilization with load-bearing applications that can be used under the harshest

environmental conditions, from the Bronze Age onwards. Only metallic materials encompass such diverse features as strength, hardness, workability, damage tolerance, joinability, ductility and

toughness, often combined with functional properties such as corrosion resistance, thermal and electric conductivity and magnetism.

The high and accelerating demand for load-bearing (structural) and functional metallic alloys in key sectors such as energy, construction, safety and transportation is resulting in predicted

production growth rates of up to 200 per cent until 2050.

Yet most of these metallic materials, specifically steel, aluminium, nickel and titanium, require a lot of energy when extracted and manufactured and these processes emit large amounts of

greenhouse gases and pollution.

The huge success of metallic products and industries also means that they has an important role in addressing the current environmental crisis.

The availability of metals (most of the elements used in structural alloys are among the most abundant), efficient mass producibility, low price and amenability to large-scale industrial production

(from extraction to the metal alloy) and manufacturing (downstream operations after solidification) have become a substantial environmental burden: worldwide production of metals leads to a total

energy consumption of about 53 exajoules (10^18 J) (8% of the global energy used) and almost 30% of industrial CO2-equivalent emissions (4.4 gigatons of carbon dioxide equivalent, Gt CO2eq) when

counting only steels and aluminium alloys (the largest fraction of metal use by volume)

This lecture gives an introductory overview of methods for improving the direct sustainability of structural metals, in areas including reduced-carbon-dioxide primary production, recycling, a hydrogen-based economy, scrap-compatible alloy design, contaminant tolerance of alloys and improved alloy longevity, for instance

throgh better corrosion resistance. The lecture also discusses the effectiveness and technological readiness of individual

measures and also show how novel structural materials enable improved energy efficiency through their reduced mass, higher thermal stability and better mechanical properties than currently

available alloys.

Old class material from last years on Micromechanics, tought at RWTH Aachen

Class Notes Micromechanics 2019

Raabe_MicroMech-intro-2019.pdf

PDF-Dokument [7.8 MB]

Class Notes Micromechanics 2017

PDF-Dokument [2.7 MB]

PDF-Dokument [5.3 MB]

PDF-Dokument [5.6 MB]

PDF-Dokument [3.6 MB]

PDF-Dokument [1.0 MB]

Raabe_micromechanics-polymers-and-bio-20[...]

PDF-Dokument [6.4 MB]

Micromechanicacs_Vorlesung_Def hex_2017_[...]

PDF-Dokument [4.2 MB]

Class Notes Micromechanics 2016

PDF-Dokument [2.8 MB]

PDF-Dokument [4.8 MB]

PDF-Dokument [3.9 MB]

PDF-Dokument [2.8 MB]

Class Notes Micromechanics 2015

D Raabe RWTH Aachen Max Planck Institut [...]

PDF-Dokument [8.3 MB]

D Raabe RWTH Aachen Max Planck Institut [...]

PDF-Dokument [6.2 MB]

Springer RWTH Aachen Max Planck Institut[...]

PDF-Dokument [7.2 MB]

C C Tasan RWTH Aachen Max Planck Institu[...]

PDF-Dokument [14.3 MB]

Jaya Balila Mechanical size effects-Expe[...]

PDF-Dokument [6.2 MB]

P Shantraj D Raabe RWTH Aachen Max Planc[...]

PDF-Dokument [1.5 MB]