Reprints on TWIP Steels

High-manganese steels have received much interest in recent years due to their outstanding mechanical properties combining high strength and ductility. This property profile is attributed to their high strain hardening capacity.

High-manganese steels are typically austenitic steels, i.e. they are face-centered cubic (fcc) alloys, with a high Mn content (above 20% wt.%) and additions of elements such as carbon (<1 wt.%),

silicon (<3 wt.%) and aluminum (<10 wt.%).

This steel grade exhibits different hardening mechanisms, such as transformation-induced plasticity (TRIP), twinning-induced plasticity (TWIP) or microband-induced plasticity (MBIP). The activation of these mechanisms is strongly dependent on the stacking fault energy. TRIP is observed in very low stacking fault steels (below 20 mJ m-2) and is associated with the transformation of austenite (fcc phase) into e-martensite (hexagonal close-packed phase), which in turn further acts as nucleus of a'-martensite (body-centered cubic or tetragonal phase). TWIP is observed in medium stacking fault energy steels (20–40 mJ m-2) and is characterized by the formation of deformation twins with nanometer thickness. MBIP has been recently reported in steel grades with high stacking fault energy (ca. 90 mJ m-2) and is attributed to the formation of microbands, which are in-grain shear zones that are confined by geometrically necessary boundaries or conventional grain boundaries. These microstructure features (e-martensite plates, deformation twins and microbands) lead to a remarkable variety of strain hardening phenomena as they all act as effective obstacles for dislocation glide. High-manganese TWIP steels are characterized by a hierarchical microstructure refinement that includes complex dislocation and twin substructures, and their interactions. Although there are some previous studies on the strain hardening behavior in TWIP steels, the details of the underlying kinetics of the substructure evolution and its correspondence to the stress–strain and strain hardening evolution is not yet fully understood.

An ultrafine-grained 304 austenitic 18 wt.% Cr–8 wt.% Ni stainless steel with a grain size of 270 nm was synthesized by accumulative rolling (67% total reduction) and annealing (550°C, 150 s). Tensile testing reveals an extremely high yield strength of 1890 ± 50 MPa and a tensile strength of 2050 ± 30 MPa, while the elongation reaches 6 ± 1%.

Acta Materialia 97 (2015) 305 UFG stainl[...]

PDF-Dokument [2.1 MB]

The stacking fault and interfacial energies of three transformation- and twinning-induced plasticity steels (TRIP/TWIP) (Fe–22/25/ 28Mn–3Al–3Si wt.%) were determined by experimental and theoreti

TWIP steel Mn stacking fault energy aust[...]

PDF-Dokument [2.4 MB]

This work is about the development and application of a multiscale dislocation density-based constitutive model for the strain-hardening behavior in twinning-induced plasticity (TWIP) steels. The appr

TWIP-model-experiments-Acta-Nov-2013.pdf

PDF-Dokument [1.8 MB]

We investigated the hydrogen embrittlement of a Fe–18Mn–1.2%C (wt.%) twinning-induced plasticity steel, focusing on the influence of deformation twins on hydrogen-assisted cracking.

Acta-Mater-hydrogen-induced-cracking-201[...]

PDF-Dokument [4.0 MB]

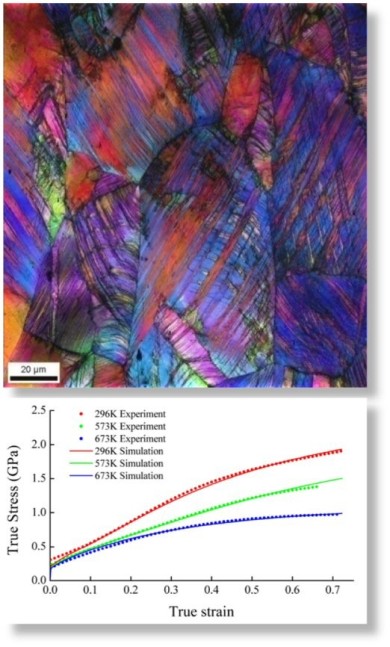

Study on the dislocation and twin substructure during strain hardening of an Fe–22 wt.% Mn–0.6 wt.% C TWIP steel

Acta 59 (2011) ECCI-Fe-Mn-C.pdf

PDF-Dokument [2.5 MB]

Study of internal stresses in a TWIP steel analyzing transient and permanent softening during reverse shear tests

J Mater Sc reverse shear tests TWIP.pdf

PDF-Dokument [416.6 KB]

Grain size and texture effects on deformation twinning in a Fe–22 wt.% Mn–0.6 wt.% C TWIP steel

Gutierrez-Urrutia et al. Mater-Sc-Engin-[...]

PDF-Dokument [2.1 MB]

ECCI: Electron channeling contrast imaging of twins and dislocations in twinning-induced plasticity steels under controlled diffraction conditions in a scanning electron microscope

ScriptaMater61(2009)737-740.pdf

PDF-Dokument [422.5 KB]

Study of deformation twinning and planar slip in a TWIP steel by Electron Channeling Contrast Imaging in a SEM

Reprint-TWIP-MSF.702-703.523.pdf

PDF-Dokument [2.3 MB]

Hydrogen-induced cracking

Hydrogen-embrittlement-Scripta_Fe-Mn-C-H[...]

PDF-Dokument [710.9 KB]

Here we study the influence of grain size on the strain hardening of two Fe–22Mn–0.6C (wt.%) twinning-induced plasticity steels with average grain sizes of 3 and 50 um, respectively. The grain siz

Scripta 2012-Viewpoint-High-Mn.pdf

PDF-Dokument [797.9 KB]

Reeh_AM_2012-ab-initio-elastic-modul.pdf

PDF-Dokument [887.1 KB]

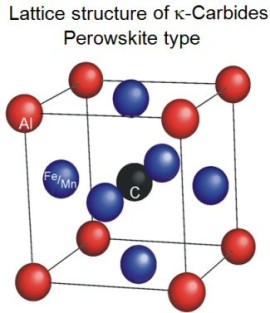

Here we study the structure and chemical composition of the kappa-carbide formed as a result of isothermal transformation in an Fe–3.0Mn–5.5Al–0.3C alloy using transmission electron microscopy a

APT weight reduced kappa scripta viewpoi[...]

PDF-Dokument [1.0 MB]