Simulation of recrystallization

The use of models for describing recrystallization phenomena with the aim of predicting crystallographic texture, microstructure, and mechanical properties in the context of materials processing is a challenging task. This judgment is motivated by the common observation that substantial changes in recrystallization can be stimulated by small modifications in the metallurgical state (e.g. chemical purity, thermodynamic state, crystallographic texture, microstructure inhomogeneity, microstructure inheritance from preceding process steps) or in the external boundary conditions (time, temperature fields, strain fields, joint thermal and mechanical constraints). This sensitivity of recrystallization is due to the fact that most of the metallurgical mechanisms involved during texture formation in the course of recrystallization such as grain nucleation, grain boundary mobility, or impurity drag effects are thermally activated. Typically these mechanisms follow exponential functions the arguments of which may depend on some of the parameters listed above and interact with each other in a nonlinear fashion. Similarly, the microstructural state of the deformed material from which recrystallization proceeds is often not well known or not well reproduced in models. Although various types of homogenization models of crystal deformation are nowadays capable of providing a decent picture of the average behavior of the material in the course of a thermomechanical process it are often the details and inhomogeneities in the deformed structure that strongly affect recrystallization so that even a good knowledge of averages does not generally solve the open questions pending in the field of recrystallization modeling. Moreover, in real industrial materials manufacturing processes typically encountered in physical metallurgy many of the influencing factors, be they of a metallurgical or of a processing nature, are usually neither exactly known nor sufficiently well defined to apply models which require a high degree of precision with regard to the input parameters. These remarks underline that the selection of an appropriate recrystallization multiscale model for the prediction of crystallographic texture, microstructure, and properties for a given process must follow a clear concept as to what exactly is expected from such a model and what cannot be predicted by it in view of the points made above. This applies in particular to cases where a model for the simulation of recrystallization textures is to be used in conjunction with real manufacturing processes. The main challenge of using multiscale process models for recrystallization, therefore, lies in selecting the right model for a well defined task, i.e. it must be agreed which microstructural property is to be simulated and what kind of properties should be subsequently calculated from these microstructure data. From that it is obvious that no model exists which could satisfy all questions that may arise in the context of recrystallization textures. Also one has to clearly separate between the aim of predicting recrystallization textures and microstructures on the one hand and the materials properties (functional or mechanical) on the other. While the first task may by pursued by formulating an appropriate recrystallization model within the limits addressed above, the second challenge falls into the wide realm of microstructure-property theory. This means that one should generally separate between the prediction of the microstructure and the prediction of some property from that particular microstructure. Typically through-process modelers are interested in the final materials properties in the first place rather than in the details of the microstructure of a recrystallized material. The modern attitude towards this discrepancy is the commonly accepted understanding that a decent description of materials properties requires the use of internal (i.e. of microstructurally motivated) parameters which can be coupled to suited microstructure-property laws. A typical example along that philosophy would be the grain size prediction via a recrystallization model and the subsequent application of the Hall-Petch law for the estimation of the yield strength. This webpage addresses exclusively the first question, more precisely, only models for primary static recrystallization will be tackled placing particular attention on the simulation of crystallographic textures.

Dierk Raabe Philosophical Magazine cellu[...]

PDF-Dokument [8.0 MB]

Annu. Rev. Mater. Res. 2002. volume 32:53-76

Annual Review Materials Research 2002 ce[...]

PDF-Dokument [1'005.7 KB]

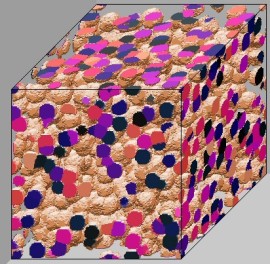

The paper is about cellular automaton models in materials science. It

gives an introduction to the fundamentals of cellular automata and reviews applications, particularly for those that predict recrystallization phenomena. Cellular automata

for recrystallization are typically discrete in time, physical space, and orientation space and often use quantities such as dislocation density and crystal orientation as state

variables. Cellular automata can be defined on a regular or nonregular two- or three-dimensional lattice considering the first, second, and third neighbor shell for the calculation of

the local driving forces. The kinetic transformation rules are usually formulated to map a linearized symmetric rate equation for sharp grain boundary segment motion. While deterministic

cellular automata directly perform cell switches by sweeping the corresponding set of neighbor cells in accord with the underlying rate equation, probabilistic cellular automata calculate

the switching probability of each lattice point and make the actual decision about a switching event by evaluating the local switching probability using a Monte Carlo step. Switches are in

a cellular automaton algorithm generally performed as a function of the previous state of a lattice point and the state of the neighboring lattice points. The transformation rules can be

scaled in terms of time and space using, for instance, the ratio of the local and the maximum possible grain boundary mobility, the local crystallographic texture, the ratio of the local

and the maximum-occurring driving forces, or appropriate scaling measures derived from a real initial specimen. The cell state update in a cellular automaton is made in synchrony for

all cells. The review deals, in particular, with the prediction of the kinetics, microstructure, and texture of recrystallization. Couplings between cellular automata and crystal plasticity

finite element models are also discussed.

Mater Sc Engin A 454–455 (2007) 433 CA a[...]

PDF-Dokument [1.2 MB]

ra_MC.pdf

PDF-Dokument [330.6 KB]

Computational Materials Science 34 (2005) 299-313

Comput Mater Sc Vol 34 (2005) 299 pinnin[...]

PDF-Dokument [1.3 MB]

This is a 2D cellular automaton simulation study on the evolution of the recrystallization texture in a 75% cold rolled interstitial free (IF) sheet steel. The model is applied to

experimentally obtained high resolution microtexture EBSD

data. The simulation is discrete in time and physical space. Orientation is treated as a continuous variable in Euler space. The dislocation density distribution is approximated from the Kikuchi

pattern quality of the experimental EBSD data. It is used for the calculation of the scalar driving force field required for the recrystallization simulation. Different models for

nucleation and for the influence of Zener-type particle pinning are presented and tested. Real time and space calibration of the simulation is obtained by using experimental input data for the

grain boundary mobility, the driving forces, and the length scale of the deformed microstructure as mapped by the high resolution EBSD experiments. The simulations predict the kinetics and

the evolution of microstructure and texture during recrystallization. Depending on

the ratio of the precipitated volume fraction and the average radius of the particles the simulations reveal three different regimes for the influence of particle pinning on the resulting

microstructures, kinetics and crystallographic textures.

CPFEM-RX.pdf

PDF-Dokument [306.5 KB]

Modelling Simul. Mater. Sci. Eng. 8 (200[...]

PDF-Dokument [865.7 KB]

MC.pdf

PDF-Dokument [198.0 KB]

Acta Materialia volume 58 (2010) 1152-1211

CPFEM_Acta_Overview_2009.pdf

PDF-Dokument [3.6 MB]

J. Strain Analysis Vol. 42

Overview Multiscale recrystallization mo[...]

PDF-Dokument [688.3 KB]

This paper discusses the most relevant multiscale models for predicting crystallographic textures formed during the primary static recrystallization of metals. Two main groups of

approaches are presented, namely those which spatially discretize the grains and the interface motion associated with recrystallization and those which treat these phenomena in an

Avrami-type statistical fashion. The article gives a concise review of the methods, placing

particular attention on their strengths and weaknesses in the context of process modelling, of conceptual aspects, and of the data sets required as input for practically applying the

models to the prediction of crystallographic textures in the course of metallurgical processes.

Acta Materialia 61 (2013) 5504-5517

Zheng et al Acta Materialia 2013 DP stee[...]

PDF-Dokument [2.1 MB]

The concurrent ferrite recrystallization and austenitic transformation during intercritical annealing of cold-rolled DP steels is investigated by cellular automaton (CA) modeling. The

simulations provide insight into the microstructural phenomena that result from the interaction of primary recrystallization and phase transformation. We find that the interaction between

ferrite recrystallization and austenite formation affects not only the transformation kinetics but also the morphology and spatial distribution of the austenite. From this we can interpret

experimental data of the observed temperature-dependent hardness and its dependence on the two metallurgical processes. The influence of the initial heating rate on subsequent isothermal

transformation kinetics and the microstructure evolution is also

obtained by the model.