Cellular automaton simulation methods for recrystallization in metals and crystallization in polymers

Raabe, D.

Cellular automata in materials science with particular reference to recrystallization simulation

(2002) Annual Review of Materials Science, 32, pp. 53-76.

Annu. Rev. Mater. Res. 2002 vol 32 p 53 [...]

PDF-Dokument [1.3 MB]

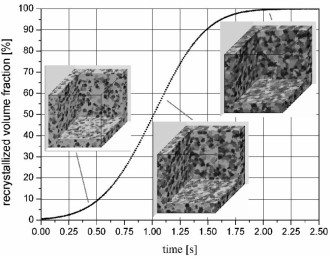

The paper is about cellular automaton models in materials science. It

gives an introduction to the fundamentals of cellular automata and reviews applications, particularly for those that predict recrystallization phenomena. Cellular automata

for recrystallization are typically discrete in time, physical space, and orientation space and often use quantities such as dislocation density and crystal orientation as state

variables. Cellular automata can be defined on a regular or nonregular two- or three-dimensional lattice considering the first, second, and third neighbor shell for the calculation

of the local driving forces. The kinetic transformation rules are usually formulated to map a linearized symmetric rate equation for sharp grain boundary segment motion.

While deterministic cellular automata directly perform cell switches by sweeping the corresponding set of neighbor cells in accord with the underlying rate equation, probabilistic cellular

automata calculate the switching probability of each lattice point and make the actual decision about a switching event by evaluating the local switching probability using a Monte Carlo

step. Switches are in a cellular automaton algorithm generally performed as a function of the previous state of a lattice point and the state of the neighboring lattice points. The

transformation rules can be scaled in terms of time and space using, for instance, the ratio of the local and the maximum possible grain boundary mobility, the local crystallographic

texture, the ratio of the local and the maximum-occurring driving forces, or appropriate scaling measures derived from

a real initial specimen. The cell state update in a cellular automaton is made in synchrony for all cells. The review deals, in particular, with the prediction of the

kinetics, microstructure, and texture of recrystallization. Couplings between cellular automata and crystal plasticity finite element models are also discussed.

Dierk Raabe overview recrystallization.p[...]

PDF-Dokument [4.3 MB]

Acta Materialia 61 (2013) 5504–5517:

The concurrent ferrite recrystallization and austenitic transformation during intercritical annealing of cold-rolled DP steels is investigated by cellular automa

Acta-Materialia-2013-recrystallization a[...]

PDF-Dokument [6.1 MB]

Cellular automaton simulation of post-dynamic austenite-to-ferrite transformation and reverse transformation in a low-carbon steel

Acta-Mater-reverse-CA-model-2012.pdf

PDF-Dokument [3.1 MB]

Acta Materialia 52 (2004) 2653 Raabe_CA_[...]

PDF-Dokument [680.2 KB]

Comput Mater Sc Vol 34 (2005) 299 pinnin[...]

PDF-Dokument [1.3 MB]

Phil Mag CA model RX 3.pdf

PDF-Dokument [7.3 MB]

Mater Sc Engin A 454–455 (2007) 433 CA a[...]

PDF-Dokument [1.2 MB]

Modelling Simul. Mater. Sci. Eng. 8 (200[...]

PDF-Dokument [865.7 KB]